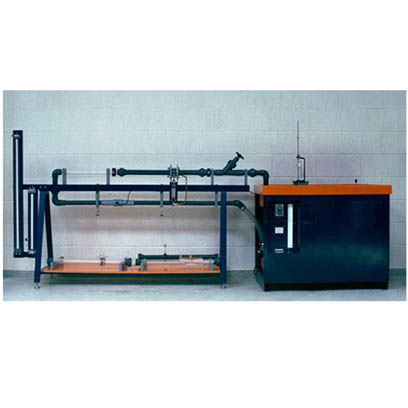

Compressive Flow Meter Demonstration

Categories: Thermodynamic LaboratoryDescription The Flow Meter Demonstration Unit is a self-contained facility to demonstrate the important characteristics of flow meters. The main elements are a service module and flow meter support s...

Product

Description

Description The Flow Meter Demonstration Unit is a self-contained facility to demonstrate the important characteristics of flow meters. The main elements are a service module and flow meter support stand. A self-priming centrifugal pump draws water from the sump tank in the service module and delivers it to a flow meter test pipe. Industrial-type flow meters mounted in test sections can be fitted into the test pipe quickly and easily. These meters have been chosen to give a variety of different metering principles and degrees of sophistication and accuracy. Some of the meters are calibrated directly in units of flow, while others involve the use of calibration charts. The pressure drop across each of the flow meters can be measured by using either the one-metre pressurised water manometer or the 0.5-metre mercury manometer supplied. Ported manometer connection valves ensure rapid bleeding of all manometer pipework. A facility exists to admit air into the hydraulic stream to demonstrate the effect on the meter’s accuracy. The discharge from the test section is controllable and is fed through a diffuser into the channel of the service module. A V-notch and rectangular notch weir can be fitted into the service module. An auxiliary channel (C9-15) accommodates the broad-crested and crump weirs, as well as the ‘H’ flume and Washington flume. Levels in the channel can be determined by using the hook and point gauge (H1). Water discharging from the flow meter on test is collected in a volumetric tank where the flow may be determined absolutely. This tank is stepped to accommodate high or low flow rates and incorporates a stilling baffle to reduce turbulence. A remote sight tube and scale connected to a tapping in the base of the volumetric tank enable an instantaneous indication of water level. Water is returned to the sump tank by a dump valve. The basic system incorporates a reference flow meter, which has been chosen for reliability and accuracy. This meter remains installed whereas other meters are selected from their storage position on the apparatus and tested as desired. In addition to being a valuable teaching aid, the apparatus brings to the laboratory a selection of instruments that can be used to support student project work. A full set of instructions is provided, including details for testing and comparison of flow meters. Specification A self-contained apparatus to demonstrate the characteristics of flow meters used in measurement of water flow through pipes or open channels Service module with reservoir, volumetric measuring tank and pump Reference turbine flow meter permanently fitted Metering devices available in various combinations to suit coursework Selection from 14 devices: Venturi Orifice Pitot Shunt gapmeter Swinging flap Volumetric rotary piston Electromagnetic Helical rotary Inferential multi-stream Current meter Broad-crested weir Crump weir ‘H’ flume Washington flume Quick and easy removal of test meters for evaluation and inspection Air entrainment facility

quick overview :

Description The Flow Meter Demonstration Unit is a self-contained facility to demonstrate the important characteristics of flow meters. The main elements are a service module and flow meter support stand. A self-priming centrifugal pump draws water from the sump tank in the service module and delivers it to a flow meter test pipe. Industrial-type flow meters mounted in test sections can be fitted into the test pipe quickly and easily. These meters have been chosen to give a variety of different metering principles and degrees of sophistication and accuracy. Some of the meters are calibrated directly in units of flow, while others involve the use of calibration charts. The pressure drop across each of the flow meters can be measured by using either the one-metre pressurised water manometer or the 0.5-metre mercury manometer supplied. Ported manometer connection valves ensure rapid bleeding of all manometer pipework. A facility exists to admit air into the hydraulic stream to demonstrate the effect on the meter’s accuracy. The discharge from the test section is controllable and is fed through a diffuser into the channel of the service module. A V-notch and rectangular notch weir can be fitted into the service module. An auxiliary channel (C9-15) accommodates the broad-crested and crump weirs, as well as the ‘H’ flume and Washington flume. Levels in the channel can be determined by using the hook and point gauge (H1). Water discharging from the flow meter on test is collected in a volumetric tank where the flow may be determined absolutely. This tank is stepped to accommodate high or low flow rates and incorporates a stilling baffle to reduce turbulence. A remote sight tube and scale connected to a tapping in the base of the volumetric tank enable an instantaneous indication of water level. Water is returned to the sump tank by a dump valve. The basic system incorporates a reference flow meter, which has been chosen for reliability and accuracy. This meter remains installed whereas other meters are selected from their storage position on the apparatus and tested as desired. In addition to being a valuable teaching aid, the apparatus brings to the laboratory a selection of instruments that can be used to support student project work. A full set of instructions is provided, including details for testing and comparison of flow meters. Specification A self-contained apparatus to demonstrate the characteristics of flow meters used in measurement of water flow through pipes or open channels Service module with reservoir, volumetric measuring tank and pump Reference turbine flow meter permanently fitted Metering devices available in various combinations to suit coursework Selection from 14 devices: Venturi Orifice Pitot Shunt gapmeter Swinging flap Volumetric rotary piston Electromagnetic Helical rotary Inferential multi-stream Current meter Broad-crested weir Crump weir ‘H’ flume Washington flume Quick and easy removal of test meters for evaluation and inspection Air entrainment facility

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.