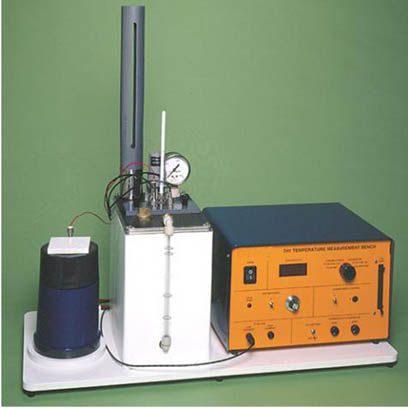

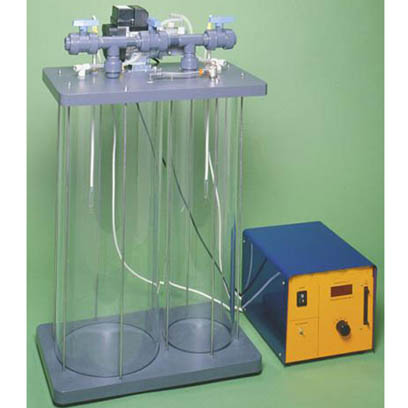

Computer Controlled Heat Exchanger Service Module For Teaching

Categories: Thermodynamic LaboratoryDescription This is a service unit, to allow the operation of one of the range of small-scale heat exchanger systems. It provides controlled cold water flow, bi-directional hot water flow and the ins...

Product

Description

Description This is a service unit, to allow the operation of one of the range of small-scale heat exchanger systems. It provides controlled cold water flow, bi-directional hot water flow and the instrumentation required to do a series of in-depth investigations into heat exchanger performance. The individual heat exchangers can be quickly changed over, to allow comparisons between different types of heat exchanger to be made. This is requires a user supplied personal computer for the operator interface. The computer connects the using a USB interface, providing a simple and straightforward installation and set-up procedure. Once the appropriate heat exchanger has been installed and setup, all other functions can be performed under computer control. Appropriate measures have been implemented so that in the case of a computer failure or communications breakdown, the system shuts itself down in a safe manner. Hardware Description The service unit provides two fluid streams to the heat exchanger, a hot water stream and a cold water stream. The hot water stream is heated in a vessel fitted with an electric heater. The heater is switched on and off by a solid state relay (SSR) which is under software control. A thermostat limits the maximum water temperature to 85°C for operator safety. A gear pump circulates water from the vessel, through the heat exchanger and back into the heater vessel. Both the pump speed and direction are under software control, allowing for co-current and counter-current investigations over a wide range of flow rates. The cold water stream is generated from a mains water supply. The flow through the heat exchanger is adjusted by a variable flow valve, again under software control. A manually adjustable pressure regulator is used to minimise the effect of mains pressure fluctuations. Conditioning circuits for up to 10 K-type thermocouples are included, (the thermocouples themselves are supplied with the heat exchangers). The instrumentation also includes flow meters to measure the flow rates of the two fluid streams. Switching on the unit puts it into ‘Standby’ mode. From this mode it is necessary for a regular series of pulses to be received from the software (via the built in USB interface) to fully power up the unit. This ensures that unless the control software is running, the heaters, the pump and the cold water control valve cannot be switched on. The unit also includes an emergency stop switch. All electrical circuits are located in a bench mounted ABS supporting base, and protected by a Residual Current Device for operator safety. The ABS base includes a drip tray and drain tap in case of water spillage or leakage. Specification Benchtop service unit, designed to accommodate a range of different small-scale heat exchangers Comprises hot water vessel, hot water recirculation pump, cold water control system, computer interface and all necessary instrumentation The hot water vessel is made from clear acrylic (for visibility) and includes a 2kW heater with thermostatic over-temperature cut-out and low water level detection. The hot water pump is bi-directional (to allow co-current and counter- current investigations without re-configuring the hardware) and the flow rate is under computer control The cold water system includes a manually adjustable pressure regulator and a flow control valve which is under computer control Flow rates for both fluid streams in excess of 5 l/min are achievable, but this may be restricted by some designs of heat exchanger. Up to 10 temperatures (K-type thermocouples) can be monitored using the service unit. Operating range, 0-75°C, resolution 0.1°C Two flow meters are included, operating range 0.2 to 9 l/min resolution 0.1 l/min All data is available to a (user-supplied) Windows PC, via a USB interface. This computer is also used to control the flow rates, hot water temperature, and hot water direction Full software for educational use is included A comprehensive instruction manual is included Key Features Small-scale, benchtop equipment Fast response times allow in-depth investigations in a short time Representative of industrial heat exchangers Multiple, industrially representative heat exchangers available All functions computer controlled, including reversing of one of the fluid streams for co-current and counter-current investigations

quick overview :

Description This is a service unit, to allow the operation of one of the range of small-scale heat exchanger systems. It provides controlled cold water flow, bi-directional hot water flow and the instrumentation required to do a series of in-depth investigations into heat exchanger performance. The individual heat exchangers can be quickly changed over, to allow comparisons between different types of heat exchanger to be made. This is requires a user supplied personal computer for the operator interface. The computer connects the using a USB interface, providing a simple and straightforward installation and set-up procedure. Once the appropriate heat exchanger has been installed and setup, all other functions can be performed under computer control. Appropriate measures have been implemented so that in the case of a computer failure or communications breakdown, the system shuts itself down in a safe manner. Hardware Description The service unit provides two fluid streams to the heat exchanger, a hot water stream and a cold water stream. The hot water stream is heated in a vessel fitted with an electric heater. The heater is switched on and off by a solid state relay (SSR) which is under software control. A thermostat limits the maximum water temperature to 85°C for operator safety. A gear pump circulates water from the vessel, through the heat exchanger and back into the heater vessel. Both the pump speed and direction are under software control, allowing for co-current and counter-current investigations over a wide range of flow rates. The cold water stream is generated from a mains water supply. The flow through the heat exchanger is adjusted by a variable flow valve, again under software control. A manually adjustable pressure regulator is used to minimise the effect of mains pressure fluctuations. Conditioning circuits for up to 10 K-type thermocouples are included, (the thermocouples themselves are supplied with the heat exchangers). The instrumentation also includes flow meters to measure the flow rates of the two fluid streams. Switching on the unit puts it into ‘Standby’ mode. From this mode it is necessary for a regular series of pulses to be received from the software (via the built in USB interface) to fully power up the unit. This ensures that unless the control software is running, the heaters, the pump and the cold water control valve cannot be switched on. The unit also includes an emergency stop switch. All electrical circuits are located in a bench mounted ABS supporting base, and protected by a Residual Current Device for operator safety. The ABS base includes a drip tray and drain tap in case of water spillage or leakage. Specification Benchtop service unit, designed to accommodate a range of different small-scale heat exchangers Comprises hot water vessel, hot water recirculation pump, cold water control system, computer interface and all necessary instrumentation The hot water vessel is made from clear acrylic (for visibility) and includes a 2kW heater with thermostatic over-temperature cut-out and low water level detection. The hot water pump is bi-directional (to allow co-current and counter- current investigations without re-configuring the hardware) and the flow rate is under computer control The cold water system includes a manually adjustable pressure regulator and a flow control valve which is under computer control Flow rates for both fluid streams in excess of 5 l/min are achievable, but this may be restricted by some designs of heat exchanger. Up to 10 temperatures (K-type thermocouples) can be monitored using the service unit. Operating range, 0-75°C, resolution 0.1°C Two flow meters are included, operating range 0.2 to 9 l/min resolution 0.1 l/min All data is available to a (user-supplied) Windows PC, via a USB interface. This computer is also used to control the flow rates, hot water temperature, and hot water direction Full software for educational use is included A comprehensive instruction manual is included Key Features Small-scale, benchtop equipment Fast response times allow in-depth investigations in a short time Representative of industrial heat exchangers Multiple, industrially representative heat exchangers available All functions computer controlled, including reversing of one of the fluid streams for co-current and counter-current investigations

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.