Computer Controlled Heat Transfer Teaching

Categories: Thermodynamic LaboratoryComputer Controlled Heat Transfer Teaching Equipment with accessories Description The service unit is housed in a robust steel enclosure and designed for use on a bench or table. It provides control...

Product

Description

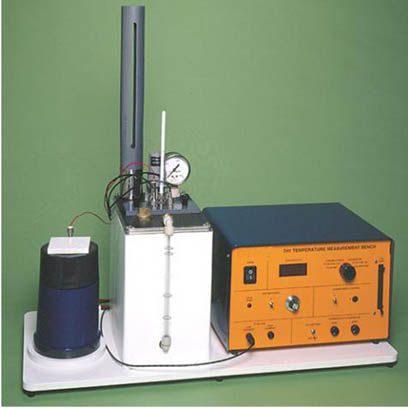

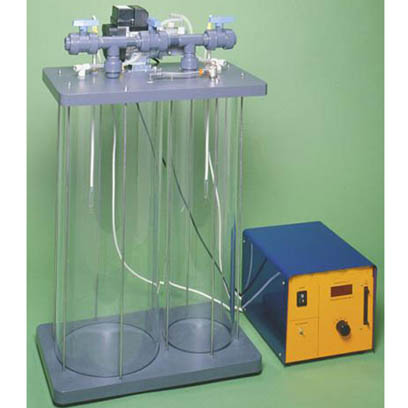

Computer Controlled Heat Transfer Teaching Equipment with accessories Description The service unit is housed in a robust steel enclosure and designed for use on a bench or table. It provides control outputs to the accessories, and instrumentation inputs from the accessories. Outputs: A stabilised, variable DC supply to the heater of the heat transfer accessory under evaluation Drive to flow-regulation valves. Drive to the variable-speed air blowers used. Inputs and Instrumentation: Temperatures: (up to 10 off, dependant on accessory being used) Heater voltage: (All accessories) Heater current: (All accessories) Heat radiated Light radiated Air velocity Cooling water flowrate In manual mode, the outputs listed above are under control of potentiometers on the front panel of the unit. In remote mode the outputs to the accessories are controlled by the computer. A ‘Watchdog’ system is implemented in remote mode to ensure operator and equipment safety in event of a computer or communications failure. In both modes the signals from the accessory can be shown on the front panel displays. Selector switches are used to select the chosen signal onto one of the two displays. These signals are also available on the USB interface for datalogging on the computer (even if the computer is not controlling the equipment). Specification

- A benchtop service unit designed to interface to a range of heat transfer accessories

- Provides a variable, stabilised 0-24V DC supply to the heater of the heat transfer accessory, with a current capability of 9 amp

- Provides a drive signal for a proportioning solenoid valve used for flow control

- Provides a control signal to a variable speed blower used for generating airflow

- 10 temperature inputs and conditioning circuits for K-type thermocouples:

- 9 off, 0-133°C, resolution <0.1°C

- 1 off, 0-500°C, resolution <0.15°C

- Instrumentation inputs for heater voltage, heater current, air flow, water flow, radiation and light meter

- Integral USB interface, and educational software for all accessories

- Outputs can be controlled manually from the front panel, or controlled by the software from a user supplied PC

- Watchdog circuit for operator and equipment safety in case of computer or interface failure when being controlled remotely(e.g. over a network or the internet using user written software)

- Easy interfacing to 3rd party software eg LabView, MatLab

quick overview :

Computer Controlled Heat Transfer Teaching Equipment with accessories Description The service unit is housed in a robust steel enclosure and designed for use on a bench or table. It provides control outputs to the accessories, and instrumentation inputs from the accessories. Outputs: A stabilised, variable DC supply to the heater of the heat transfer accessory under evaluation Drive to flow-regulation valves. Drive to the variable-speed air blowers used. Inputs and Instrumentation: Temperatures: (up to 10 off, dependant on accessory being used) Heater voltage: (All accessories) Heater current: (All accessories) Heat radiated Light radiated Air velocity Cooling water flowrate In manual mode, the outputs listed above are under control of potentiometers on the front panel of the unit. In remote mode the outputs to the accessories are controlled by the computer. A ‘Watchdog’ system is implemented in remote mode to ensure operator and equipment safety in event of a computer or communications failure. In both modes the signals from the accessory can be shown on the front panel displays. Selector switches are used to select the chosen signal onto one of the two displays. These signals are also available on the USB interface for datalogging on the computer (even if the computer is not controlling the equipment). Specification

- A benchtop service unit designed to interface to a range of heat transfer accessories

- Provides a variable, stabilised 0-24V DC supply to the heater of the heat transfer accessory, with a current capability of 9 amp

- Provides a drive signal for a proportioning solenoid valve used for flow control

- Provides a control signal to a variable speed blower used for generating airflow

- 10 temperature inputs and conditioning circuits for K-type thermocouples:

- 9 off, 0-133°C, resolution <0.1°C

- 1 off, 0-500°C, resolution <0.15°C

- Instrumentation inputs for heater voltage, heater current, air flow, water flow, radiation and light meter

- Integral USB interface, and educational software for all accessories

- Outputs can be controlled manually from the front panel, or controlled by the software from a user supplied PC

- Watchdog circuit for operator and equipment safety in case of computer or interface failure when being controlled remotely(e.g. over a network or the internet using user written software)

- Easy interfacing to 3rd party software eg LabView, MatLab

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.