Laboratory Reactor

Categories:Laboratory Reactor Main characteristics of the pilot Laboratory Reactor Bench apparatus Flow switch of the condenser cooling water for operators safety Temperature switch to protect heating ele...

Product

Description

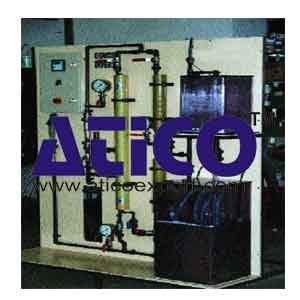

Laboratory Reactor

Main characteristics of the pilot

Laboratory Reactor- Bench apparatus

- Flow switch of the condenser cooling water for operators safety

- Temperature switch to protect heating element

- Borosilicate glass and stainless steel AISI 316L manufacturing

- Rigid process pipes

- Downwards dismantling of reactor vessel without dismantling upper section of reactor

- Temperature control unit with thermal oil medium

- Heating control with set point programmer

- Variable reflux column head controlled by ATEX solenoid valve

Principle of Working

The reaction is a fundamental operation of the chemical industry, allowing the production, from simple molecules (reagents), of increasingly complex compounds destined for a growing number of industries (chemistry, pharmacy etc). The reactor is of the well-mixed type and operates in a batch process: the quantity of reagent is introduced at the start of processing in a single quantity or controlled over time. The reaction mixture is brought to the required temperature (fixed or programmed according to time). The presence of a distillation column makes it possible to evaporate a solvent in the same reactor vessel, to separate the reaction products once the desired conversion rate has been reached, or to remove one of the products of the reaction (in the case of reversible reactions to displace the thermodynamic equilibrium). At the end of processing, the products of the reaction are collected after cooling. The reactor also allows “batch” crystallizations to be performed (the borosilicate glass vessel option allows the crystal nucleation and growth phase to be seen).

Teaching objectives

- Study of the following experimental parameters :

- Study of reaction kinetics.

- Study of reversible or irreversible reactions.

- Study of evaporation.

- Crystallization by evaporation, chemical reaction or cooling.

Total reflux reactions.

- Calculations :

- Mass balance.

- Conversion rate.

Technical Specifications of Laboratory Reactor

Equipment:- Borosilicate glass feed tank for storing reagents, graduated with product vacuum supply system for filling reagents.

- “Grignard” type cylindrical reactor: AISI 316L stainless steel vessel, with insulated double jacket for thermal oil medium and flush mounted drain valve; borosilicate glass lid.

- Variable speed stirring assembly in AISI 316L stainless steel with helical type rotor.

- Reaction mixture cooling coil in AISI 316L stainless steel.

- Borosilicate glass column in one piece 250 mm length with “MULTIKNIT” type packing in AISI 316L stainless steel.

- Borosilicate glass column head, with temperature plug, fitted with a solenoid valve to control the reflux rate.

- Vertical condenser, borosilicate glass body, AISI 316L stainless steel exchanger, single effet with baffles.

- Borosilicate glass distillate cooler.

- Graduated borosilicate glass distillate receiver.

- AISI 316L stainless steel connecting tubes for the process and reinforced PVC for cooling fluid tube.

- Support framework with AISI 304L stainless steel tubes, aluminium connecting nuts and adjustable feet.

Instrumentation:

- Cooling water feed to condenser fitted with variable area flowmeter with its adjusting valve and water flow switch to turn off heating in case of lack of cooling water.

- Temperature control unit with thermal oil medium.

- Command and control cabinet fitted with an emergency stop, operating buttons and the following interfaces:

- Electronic timer controlling valve at the head of the column.

- Reactor or thermal oil medium temperature controller.

- Stirring speed controller.

- Digital stirring speed indicator. Two digital temperature indicators with four Pt100 Ω type probes.

Dimensions and weight

- 1000 mm x 600 mm x 1500 mm ~ 80 kg.

Essential requirements

- 230 V / 50 Hz / Single phase: 3 kW.

- Cold water 20°C / 3 bar: 1 m³/h.

- Vacuum 100 mbar: 2 Nm³/h

- Drain.

quick overview :

Laboratory Reactor

Main characteristics of the pilot

Laboratory Reactor- Bench apparatus

- Flow switch of the condenser cooling water for operators safety

- Temperature switch to protect heating element

- Borosilicate glass and stainless steel AISI 316L manufacturing

- Rigid process pipes

- Downwards dismantling of reactor vessel without dismantling upper section of reactor

- Temperature control unit with thermal oil medium

- Heating control with set point programmer

- Variable reflux column head controlled by ATEX solenoid valve

Principle of Working

The reaction is a fundamental operation of the chemical industry, allowing the production, from simple molecules (reagents), of increasingly complex compounds destined for a growing number of industries (chemistry, pharmacy etc). The reactor is of the well-mixed type and operates in a batch process: the quantity of reagent is introduced at the start of processing in a single quantity or controlled over time. The reaction mixture is brought to the required temperature (fixed or programmed according to time). The presence of a distillation column makes it possible to evaporate a solvent in the same reactor vessel, to separate the reaction products once the desired conversion rate has been reached, or to remove one of the products of the reaction (in the case of reversible reactions to displace the thermodynamic equilibrium). At the end of processing, the products of the reaction are collected after cooling. The reactor also allows “batch” crystallizations to be performed (the borosilicate glass vessel option allows the crystal nucleation and growth phase to be seen).

Teaching objectives

- Study of the following experimental parameters :

- Study of reaction kinetics.

- Study of reversible or irreversible reactions.

- Study of evaporation.

- Crystallization by evaporation, chemical reaction or cooling.

Total reflux reactions.

- Calculations :

- Mass balance.

- Conversion rate.

Technical Specifications of Laboratory Reactor

Equipment:- Borosilicate glass feed tank for storing reagents, graduated with product vacuum supply system for filling reagents.

- “Grignard” type cylindrical reactor: AISI 316L stainless steel vessel, with insulated double jacket for thermal oil medium and flush mounted drain valve; borosilicate glass lid.

- Variable speed stirring assembly in AISI 316L stainless steel with helical type rotor.

- Reaction mixture cooling coil in AISI 316L stainless steel.

- Borosilicate glass column in one piece 250 mm length with “MULTIKNIT” type packing in AISI 316L stainless steel.

- Borosilicate glass column head, with temperature plug, fitted with a solenoid valve to control the reflux rate.

- Vertical condenser, borosilicate glass body, AISI 316L stainless steel exchanger, single effet with baffles.

- Borosilicate glass distillate cooler.

- Graduated borosilicate glass distillate receiver.

- AISI 316L stainless steel connecting tubes for the process and reinforced PVC for cooling fluid tube.

- Support framework with AISI 304L stainless steel tubes, aluminium connecting nuts and adjustable feet.

Instrumentation:

- Cooling water feed to condenser fitted with variable area flowmeter with its adjusting valve and water flow switch to turn off heating in case of lack of cooling water.

- Temperature control unit with thermal oil medium.

- Command and control cabinet fitted with an emergency stop, operating buttons and the following interfaces:

- Electronic timer controlling valve at the head of the column.

- Reactor or thermal oil medium temperature controller.

- Stirring speed controller.

- Digital stirring speed indicator. Two digital temperature indicators with four Pt100 Ω type probes.

Dimensions and weight

- 1000 mm x 600 mm x 1500 mm ~ 80 kg.

Essential requirements

- 230 V / 50 Hz / Single phase: 3 kW.

- Cold water 20°C / 3 bar: 1 m³/h.

- Vacuum 100 mbar: 2 Nm³/h

- Drain.

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.