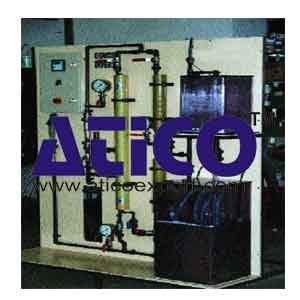

Manual Absorption Desorption Pilot Plant

Categories:Manual Absorption Desorption Pilot Plant Main characteristics of the pilot Manual Absorption Desorption Pilot Plant Industrial instrumentation Borosilicate glass and stainless steel AISI 316L man...

Product

Description

Manual Absorption Desorption Pilot Plant

Main characteristics of the pilot

Manual Absorption Desorption Pilot Plant- Industrial instrumentation

- Borosilicate glass and stainless steel AISI 316L manufacturing

- Rigid process pipes

- Cooling at the bottom of the column

- Continuous or batch processes

Principle of Working:

The absorption process is a mass transfer of a compound present in a gaseous phase to a liquid phase by dissolution. The inverse transfer operation of a gas dissolved in a liquid using an inert gas is called desorption. These processes are done in a packed column between a climbing gaseous effluent and a solution or a solvent flowing down (counter-current operation). The presence of packing increases the liquid-gas exchange surface, therefore the mass transfer. A heat exchanger at the bottom of column allows to cool the out flowing solution (the absorption is an exothermic reaction); in batch mode this heat exchanger allows to check the influence of the temperature on the efficiency of the absorption. A static mixer, situated upstream of the gas introduction in the column, is used to dilute the gas to process with an inert gas (air or nitrogen).

Teaching objectives

- Study of the following experimental parameters :

- Study of the hydrodynamics of the column.

- Study of the absorption without chemical reaction.

- Study of the absorption with chemical reaction.

- Influence of the head loss on the efficiency of the column.

- Continuous or batch functioning.

- Study of the desorption by an inert gas.

- Calculations :

- Thermal balance.

- Mass balance.

- Determination of the number of theoretical stages (McCABE and THIELE, KREMSER and BROWN).

- Determination of the number of transfer units

- Coefficient of mass transfer.

Technical Specifications of Manual Absorption Desorption Pilot Plant

Equipment:- Storage tank of the feeding solution or the feeding solvent in polyethylene.

- Feed solution metering pump, AISI 316L stainless steel body, P.T.F.E. diaphragm, manual control..

- Traps for pressure drop measurement.

- Column in borosilicate glass, in three elements with "RASCHIG" rings packing in borosilicate glass.

- Four plates made of AISI 316L stainless steel, equipped each with sampling valves (gaseous phase and liquid phase) and with a temperature plug.

- Head of column in borosilicate glass, NB50, with introduction of the solution or the solvent and draining off the gaseous phase.

- Bottom of column in borosilicate glass, NB50, with introduction of the gaseous phase.

- Vertical heat exchanger, borosilicate glass body AISI 316L stainless steel exchanger.

- Adjustable liquid seal.

- Solution receiver in borosilicate glass, equipped with a draining valve made of AISI 316L stainless steel.

- AISI 316L stainless steel connecting tubes for the process and reinforced PVC for cooling fluid tube.

- Support framework with AISI 304L stainless steel tubes, aluminium connecting nuts and adjustable feet.

Instrumentation:

- Supply of the cooling water of the heat exchanger equipped with a variable area lowmeter with its adjusting valve.

- Measurement of the column pressure drop by differential “U” type manometer.

- Control cabinet, IP55, equipped with an emergency stop button, operating buttons and the following interfaces :

- Two temperature digital indicators with nine Pt100 Ω type probes

Dimensions and weight

- 1, 3 x m 0, 75 x m 2, 9 m ~ 120 kg.

Essential requirements

- 230 V / 50 Hz / Single phase : 0.5 kW.

- Cold water 20 °C / 3 bar : 600 l/h.

- Compressed air / 6 bar : 20 Nm3/hs

- Reactive gas with relief valve 3 bar : 1 Nm3/h

- Evacuation of the toxic gases

- Drain

quick overview :

Manual Absorption Desorption Pilot Plant

Main characteristics of the pilot

Manual Absorption Desorption Pilot Plant- Industrial instrumentation

- Borosilicate glass and stainless steel AISI 316L manufacturing

- Rigid process pipes

- Cooling at the bottom of the column

- Continuous or batch processes

Principle of Working:

The absorption process is a mass transfer of a compound present in a gaseous phase to a liquid phase by dissolution. The inverse transfer operation of a gas dissolved in a liquid using an inert gas is called desorption. These processes are done in a packed column between a climbing gaseous effluent and a solution or a solvent flowing down (counter-current operation). The presence of packing increases the liquid-gas exchange surface, therefore the mass transfer. A heat exchanger at the bottom of column allows to cool the out flowing solution (the absorption is an exothermic reaction); in batch mode this heat exchanger allows to check the influence of the temperature on the efficiency of the absorption. A static mixer, situated upstream of the gas introduction in the column, is used to dilute the gas to process with an inert gas (air or nitrogen).

Teaching objectives

- Study of the following experimental parameters :

- Study of the hydrodynamics of the column.

- Study of the absorption without chemical reaction.

- Study of the absorption with chemical reaction.

- Influence of the head loss on the efficiency of the column.

- Continuous or batch functioning.

- Study of the desorption by an inert gas.

- Calculations :

- Thermal balance.

- Mass balance.

- Determination of the number of theoretical stages (McCABE and THIELE, KREMSER and BROWN).

- Determination of the number of transfer units

- Coefficient of mass transfer.

Technical Specifications of Manual Absorption Desorption Pilot Plant

Equipment:- Storage tank of the feeding solution or the feeding solvent in polyethylene.

- Feed solution metering pump, AISI 316L stainless steel body, P.T.F.E. diaphragm, manual control..

- Traps for pressure drop measurement.

- Column in borosilicate glass, in three elements with "RASCHIG" rings packing in borosilicate glass.

- Four plates made of AISI 316L stainless steel, equipped each with sampling valves (gaseous phase and liquid phase) and with a temperature plug.

- Head of column in borosilicate glass, NB50, with introduction of the solution or the solvent and draining off the gaseous phase.

- Bottom of column in borosilicate glass, NB50, with introduction of the gaseous phase.

- Vertical heat exchanger, borosilicate glass body AISI 316L stainless steel exchanger.

- Adjustable liquid seal.

- Solution receiver in borosilicate glass, equipped with a draining valve made of AISI 316L stainless steel.

- AISI 316L stainless steel connecting tubes for the process and reinforced PVC for cooling fluid tube.

- Support framework with AISI 304L stainless steel tubes, aluminium connecting nuts and adjustable feet.

Instrumentation:

- Supply of the cooling water of the heat exchanger equipped with a variable area lowmeter with its adjusting valve.

- Measurement of the column pressure drop by differential “U” type manometer.

- Control cabinet, IP55, equipped with an emergency stop button, operating buttons and the following interfaces :

- Two temperature digital indicators with nine Pt100 Ω type probes

Dimensions and weight

- 1, 3 x m 0, 75 x m 2, 9 m ~ 120 kg.

Essential requirements

- 230 V / 50 Hz / Single phase : 0.5 kW.

- Cold water 20 °C / 3 bar : 600 l/h.

- Compressed air / 6 bar : 20 Nm3/hs

- Reactive gas with relief valve 3 bar : 1 Nm3/h

- Evacuation of the toxic gases

- Drain

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.