Pressure Measurement And Calibration TH

Categories: Thermodynamic LaboratoryDescription A benchtop unit designed to introduce students to pressure, pressure scales and common devices available to measure pressure. The equipment utilises a Deadweight Pressure Calibrator (DPC...

Product

Description

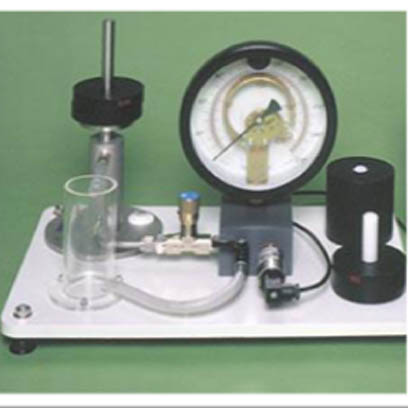

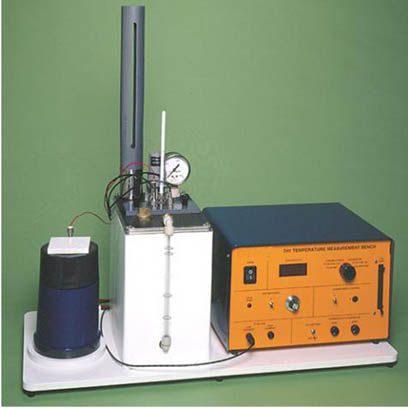

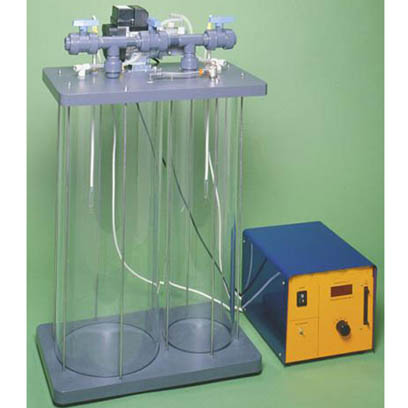

Description A benchtop unit designed to introduce students to pressure, pressure scales and common devices available to measure pressure. The equipment utilises a Deadweight Pressure Calibrator (DPC) to generate a number of predetermined pressures. This is connected to a Bourdon gauge and electronic pressure sensor to enable their characteristics, including accuracy and linearity, to be determined. The DPC consists of a precision ground piston and cylinder with a set of weights giving an operating range of 20 kNm-2 to 200 kNm-2. The Bourdon gauge and pressure sensor are mounted on a manifold block with a separate reservoir to contain the hydraulic fluid (water for safety and ease of use). Valves enable easy priming, restricted flow of water to demonstrate the application of damping and the connection of alternative devices for calibration. The gauge supplied is a traditional six inch diameter industrial instrument but fitted with a clear rotary scale to enable observation of the Bourdon tube and indicator mechanism. The scale is calibrated in degrees of rotation (independent of units of pressure) in addition to the usual scale calibrated in units of kNm-2. The electronic pressure sensor supplied incorporates a semiconductor diaphragm that deflects when pressure is applied by the working fluid. This deflection generates a voltage output that is proportional to the applied pressure. All power supplies, signal conditioning circuitry etc, are contained in an electrical console with appropriate current protection devices and an RCD for operator protection. The output voltage from the pressure sensor is displayed on a digital meter. An additional conditioning circuit with user-adjustable zero and span control enables the output to be displayed as a direct reading pressure meter calibrated in units of pressure. Both signals are simultaneously routed to an I/O port for connection to a PC when using an optional interface device with educational software package. Specification A benchtop unit comprising a simple Deadweight Pressure Calibrator with weights to generate a range of predetermined pressures. This is connected to a Bourdon gauge and electronic pressure sensor. The Bourdon gauge incorporates an arbitrary scale in addition to the pressure scale and a clear acrylic front face enables observation of the Bourdon tube and the operating mechanism. A reservoir with isolating valve enables the calibrator, Bourdon gauge and pressure sensor to be easily primed An electrical console houses the necessary electronics with current protection devices and an RCD for operator protection. A digital meter with selector switch displays the output from the pressure sensor, as well as the conditioned reading in engineering units. Corresponding signals are routed to an I/O port for connection to a PC. An optional interface device with educational software package is available The Deadweight Pressure Calibrator, Bourdon gauge and pressure sensor are mounted on a common PVC baseplate. The electrical console is free-standing Pressure sensors, manometers or Bourdon gauges other than those supplied can be calibrated over the range 20 kNm-2 to 200 kNm-2 A comprehensive instruction manual is included with a range of fully detailed laboratory teaching exercises. Key Features ncludes simple Deadweight Pressure Calibrator using water for safety and ease of use Bourdon gauge and electronic sensor included for calibration Operating mechanism of Bourdon gauge visible through clear scale Electrical sensor can be logged using a PC (not supplied). Optional teaching software is available for data logging

quick overview :

Description A benchtop unit designed to introduce students to pressure, pressure scales and common devices available to measure pressure. The equipment utilises a Deadweight Pressure Calibrator (DPC) to generate a number of predetermined pressures. This is connected to a Bourdon gauge and electronic pressure sensor to enable their characteristics, including accuracy and linearity, to be determined. The DPC consists of a precision ground piston and cylinder with a set of weights giving an operating range of 20 kNm-2 to 200 kNm-2. The Bourdon gauge and pressure sensor are mounted on a manifold block with a separate reservoir to contain the hydraulic fluid (water for safety and ease of use). Valves enable easy priming, restricted flow of water to demonstrate the application of damping and the connection of alternative devices for calibration. The gauge supplied is a traditional six inch diameter industrial instrument but fitted with a clear rotary scale to enable observation of the Bourdon tube and indicator mechanism. The scale is calibrated in degrees of rotation (independent of units of pressure) in addition to the usual scale calibrated in units of kNm-2. The electronic pressure sensor supplied incorporates a semiconductor diaphragm that deflects when pressure is applied by the working fluid. This deflection generates a voltage output that is proportional to the applied pressure. All power supplies, signal conditioning circuitry etc, are contained in an electrical console with appropriate current protection devices and an RCD for operator protection. The output voltage from the pressure sensor is displayed on a digital meter. An additional conditioning circuit with user-adjustable zero and span control enables the output to be displayed as a direct reading pressure meter calibrated in units of pressure. Both signals are simultaneously routed to an I/O port for connection to a PC when using an optional interface device with educational software package. Specification A benchtop unit comprising a simple Deadweight Pressure Calibrator with weights to generate a range of predetermined pressures. This is connected to a Bourdon gauge and electronic pressure sensor. The Bourdon gauge incorporates an arbitrary scale in addition to the pressure scale and a clear acrylic front face enables observation of the Bourdon tube and the operating mechanism. A reservoir with isolating valve enables the calibrator, Bourdon gauge and pressure sensor to be easily primed An electrical console houses the necessary electronics with current protection devices and an RCD for operator protection. A digital meter with selector switch displays the output from the pressure sensor, as well as the conditioned reading in engineering units. Corresponding signals are routed to an I/O port for connection to a PC. An optional interface device with educational software package is available The Deadweight Pressure Calibrator, Bourdon gauge and pressure sensor are mounted on a common PVC baseplate. The electrical console is free-standing Pressure sensors, manometers or Bourdon gauges other than those supplied can be calibrated over the range 20 kNm-2 to 200 kNm-2 A comprehensive instruction manual is included with a range of fully detailed laboratory teaching exercises. Key Features ncludes simple Deadweight Pressure Calibrator using water for safety and ease of use Bourdon gauge and electronic sensor included for calibration Operating mechanism of Bourdon gauge visible through clear scale Electrical sensor can be logged using a PC (not supplied). Optional teaching software is available for data logging

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.