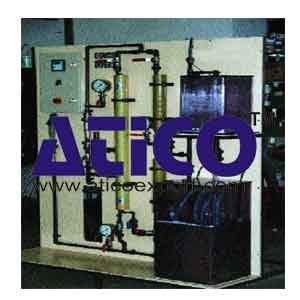

Reaction Crystallization Pilot

Categories:Reaction Crystallization Pilot The bench allows two types of crystallization : Reaction Crystallization Pilot By cooling of the mixture, while exploiting the reduced solubility of the component to sep...

Product

Description

Reaction Crystallization Pilot

The bench allows two types of crystallization :

Reaction Crystallization PilotBy cooling of the mixture, while exploiting the reduced solubility of the component to separate, at lower temperature. In crystallization by cooling, the solution to treat is stocked in a thermostatic vat, and stirred in order to maintain the component to separate in solution. The treatment at high temperature is assured by of hot water circulation (80°C to 90°C) in the jacket of the vat. When the complete solubility is gotten until the separation of the thermostatic compound, a measuring pump provides on control the transfer of mixture in the crystallizer, this one also include a vat with a double jacket in which circulate the cooling water. When the crystallization of the product we wants to separate is obtained, the solid part is discharged in a vat, through the bottom vat valve. - by evaporation of the solvent, while decreasing the solubility of the component to separate in the solution. In crystallization by evaporation, the solution to treat is immediately loaded in the crystallizer, the thermal fluid is a low-pressure steam (110°C. 1,4 bar). The generated steams are sent then in a condenser, in a cooler, and in a test-tube. The complete installation can be put under vacuum, in order to decrease the temperature of the heating thermal fluid. In this case, we can use a thermal fluid in liquid state.

Teaching objectives

- Study of liquid-liquid and solid-liquid reaction.

- Flowing back heating.

- Atmospheric pressure and reduced pressure boiling evaporation.

- Crystallization by cooling with double jacket and under vacuum.

- Study of crystallization : solubility. Over saturation.

- Balances mass and energy balance of the process.

Technical specifications of Reaction Crystallization Pilot

Reactor :- Double jacket reactor in stainless steel.

- Pressure : 0 (vacuum) to 2 bars (absolute).

- Tapping of the products without retention by bottom valve.

- Heating by refrigerant.

- Measure of the internal pressure.

- Cooling by network water circulating in the double jacket or in a coiled device

- Variable-speed stirrer 0 to 300 rpm

- Loading of solid powders

- loading of liquids under vacuum

- Sampling tube with tap

Heating unit :

- Maximum temperature 160°C, minimum temperature 30°C, refrigerant with circulation pump.

Measuring device :

- Vacuum loading

- Vacuum pump

- Variable and controlled flow

- Level measurement

- Draining valve

Condenser :

- Condensation of the water steam

- The refrigerant fluid is water from network

Distillate circuit :

- An observation device at the outlet of the condenser

- A discharge to the recipe

- A refrigerant for cooling the distillate : the refrigerant fluid is the network water

- A return circuit to the reactor

- Distillate flow measuring device

Recipe :

- 2 recipes,

- Level measurement

- Breathing

- Draining

Breathing circuit :

- The breathings are made of stainless steel pipes

Option 1 :

- Vacuum filter

- Stainless steel 316 L design

- Diameter 400 mm, height 350 mm

- Vacuum fitting connexion

- Mounted on wheels

Option 2 :

- Vacuum pump, water ring pump

- Essential requirements

- Power supply : 220 V - 50 Hz

- Heating unit 140°C, 3 bars, 10 kW

quick overview :

Reaction Crystallization Pilot

The bench allows two types of crystallization :

Reaction Crystallization PilotBy cooling of the mixture, while exploiting the reduced solubility of the component to separate, at lower temperature. In crystallization by cooling, the solution to treat is stocked in a thermostatic vat, and stirred in order to maintain the component to separate in solution. The treatment at high temperature is assured by of hot water circulation (80°C to 90°C) in the jacket of the vat. When the complete solubility is gotten until the separation of the thermostatic compound, a measuring pump provides on control the transfer of mixture in the crystallizer, this one also include a vat with a double jacket in which circulate the cooling water. When the crystallization of the product we wants to separate is obtained, the solid part is discharged in a vat, through the bottom vat valve. - by evaporation of the solvent, while decreasing the solubility of the component to separate in the solution. In crystallization by evaporation, the solution to treat is immediately loaded in the crystallizer, the thermal fluid is a low-pressure steam (110°C. 1,4 bar). The generated steams are sent then in a condenser, in a cooler, and in a test-tube. The complete installation can be put under vacuum, in order to decrease the temperature of the heating thermal fluid. In this case, we can use a thermal fluid in liquid state.

Teaching objectives

- Study of liquid-liquid and solid-liquid reaction.

- Flowing back heating.

- Atmospheric pressure and reduced pressure boiling evaporation.

- Crystallization by cooling with double jacket and under vacuum.

- Study of crystallization : solubility. Over saturation.

- Balances mass and energy balance of the process.

Technical specifications of Reaction Crystallization Pilot

Reactor :- Double jacket reactor in stainless steel.

- Pressure : 0 (vacuum) to 2 bars (absolute).

- Tapping of the products without retention by bottom valve.

- Heating by refrigerant.

- Measure of the internal pressure.

- Cooling by network water circulating in the double jacket or in a coiled device

- Variable-speed stirrer 0 to 300 rpm

- Loading of solid powders

- loading of liquids under vacuum

- Sampling tube with tap

Heating unit :

- Maximum temperature 160°C, minimum temperature 30°C, refrigerant with circulation pump.

Measuring device :

- Vacuum loading

- Vacuum pump

- Variable and controlled flow

- Level measurement

- Draining valve

Condenser :

- Condensation of the water steam

- The refrigerant fluid is water from network

Distillate circuit :

- An observation device at the outlet of the condenser

- A discharge to the recipe

- A refrigerant for cooling the distillate : the refrigerant fluid is the network water

- A return circuit to the reactor

- Distillate flow measuring device

Recipe :

- 2 recipes,

- Level measurement

- Breathing

- Draining

Breathing circuit :

- The breathings are made of stainless steel pipes

Option 1 :

- Vacuum filter

- Stainless steel 316 L design

- Diameter 400 mm, height 350 mm

- Vacuum fitting connexion

- Mounted on wheels

Option 2 :

- Vacuum pump, water ring pump

- Essential requirements

- Power supply : 220 V - 50 Hz

- Heating unit 140°C, 3 bars, 10 kW

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.