Surface Treatment Plant

Categories: Mechanical Lab Equipment ManufacturerSurface Treatment Plant Teaching Objectives of Surface Treatment Plant This system covers a wide range of themes which can be developed. Management of the intense currents. Temperature control....

Product

Description

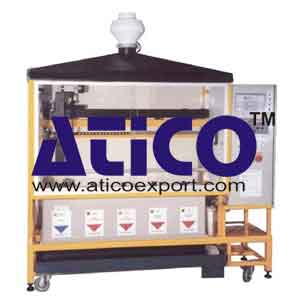

Surface Treatment Plant

Teaching Objectives of Surface Treatment Plant This system covers a wide range of themes which can be developed.- Management of the intense currents.

- Temperature control.

- Electrchemistry.

- Handling of pieces.

- Automatic.

- Study of a system with different technologies.

- Goods and people security.

- Maintenance of an automated system.

Technical specifications

A) Operative part: It is composed of a mobile frame, including:- Chemical oil cleaning station.

- Rinsing station.

- Acid dipping station.

- Acid zinc plating station.

- Horizontal translation motor.

- Vertical translation motor.

- Jib crane.

- Retention tank.

- Filtering block.

- Electrical cabinet.

- Transparent safety guard of the working area.

- Ventilation hood

- The handling of the jib cranes in the 2 axes Y and Z (horizontal and vertical) is made with a speed of displacement of about 0,2 m/s.

- Temperature control of the chemical oil cleaning bath by waves-train and static relays.

- The feeding of the electrolytic zinc plating bath is made by a current generator of 0-10 A with controlled direct current.

- Supply of the current generator from the single phase network.

- Display of tension and current.

A compact PLC with analogical inputs/outputs and TOR, PID regulation, 2 interfaces of communication. A interactive exploitation dialog terminal with 2 display lines. 20 characters. communication with the PLC on the serial line, UNI-TELWAY protocol, 12 keys function keyboard.

10 service keys and 12 numerical keys. Programming made on several application pages and alarms pages. The power supply and people protection devices : differential circuit-breaker, contactors. fuses, transformer. Current generator for the electrolytic zinc plating bath.Technical Functions of Surface Treatment Plant :

The PLC assures the following functions:- Management of 5 positions on the Y axis in order to ensure the operations of chemical oil cleaning, rinsing, acid dipping, rinsing and zinc coating.

- Management of 2 positions on axis (high and low).

- Temperature control of the chemical oil cleaning bath.

- Manual run.

- Aspiration of steams above all the tanks.

- No waste to the sewage, the wasted baths will be reconditioned in delivery cans of and sent to approved centres for the treatment.

- The sounding environment is distinctly lower to 70db.

- People security by the transparent surrounding wall locked wit a key.

- Auto-control of the door sensor by a security box.

Essential requirements

- Electric power supply : 3 x 380V + N + E. 16A.

- Sanitary water supply.

- Outside joining for draining of the noxiousness steams by 3m flexible hose.

- Inside Diameter 150 mm.

Dimensions and weight

- Length 2,4m width 0,69 m.

- Height without the hood 1,7 m.

- Height with the hood 2,25 m.

- Weight 326 kg.

- Resonant level < 70 dB(A).

quick overview :

Surface Treatment Plant

Teaching Objectives of Surface Treatment Plant This system covers a wide range of themes which can be developed.- Management of the intense currents.

- Temperature control.

- Electrchemistry.

- Handling of pieces.

- Automatic.

- Study of a system with different technologies.

- Goods and people security.

- Maintenance of an automated system.

Technical specifications

A) Operative part: It is composed of a mobile frame, including:- Chemical oil cleaning station.

- Rinsing station.

- Acid dipping station.

- Acid zinc plating station.

- Horizontal translation motor.

- Vertical translation motor.

- Jib crane.

- Retention tank.

- Filtering block.

- Electrical cabinet.

- Transparent safety guard of the working area.

- Ventilation hood

- The handling of the jib cranes in the 2 axes Y and Z (horizontal and vertical) is made with a speed of displacement of about 0,2 m/s.

- Temperature control of the chemical oil cleaning bath by waves-train and static relays.

- The feeding of the electrolytic zinc plating bath is made by a current generator of 0-10 A with controlled direct current.

- Supply of the current generator from the single phase network.

- Display of tension and current.

A compact PLC with analogical inputs/outputs and TOR, PID regulation, 2 interfaces of communication. A interactive exploitation dialog terminal with 2 display lines. 20 characters. communication with the PLC on the serial line, UNI-TELWAY protocol, 12 keys function keyboard.

10 service keys and 12 numerical keys. Programming made on several application pages and alarms pages. The power supply and people protection devices : differential circuit-breaker, contactors. fuses, transformer. Current generator for the electrolytic zinc plating bath.Technical Functions of Surface Treatment Plant :

The PLC assures the following functions:- Management of 5 positions on the Y axis in order to ensure the operations of chemical oil cleaning, rinsing, acid dipping, rinsing and zinc coating.

- Management of 2 positions on axis (high and low).

- Temperature control of the chemical oil cleaning bath.

- Manual run.

- Aspiration of steams above all the tanks.

- No waste to the sewage, the wasted baths will be reconditioned in delivery cans of and sent to approved centres for the treatment.

- The sounding environment is distinctly lower to 70db.

- People security by the transparent surrounding wall locked wit a key.

- Auto-control of the door sensor by a security box.

Essential requirements

- Electric power supply : 3 x 380V + N + E. 16A.

- Sanitary water supply.

- Outside joining for draining of the noxiousness steams by 3m flexible hose.

- Inside Diameter 150 mm.

Dimensions and weight

- Length 2,4m width 0,69 m.

- Height without the hood 1,7 m.

- Height with the hood 2,25 m.

- Weight 326 kg.

- Resonant level < 70 dB(A).

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.