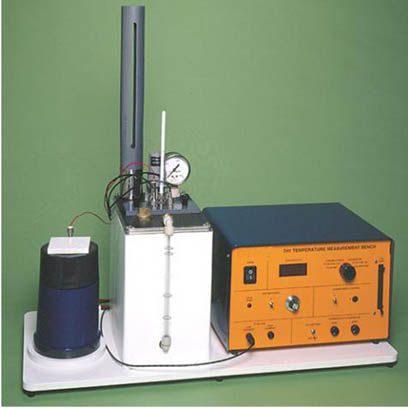

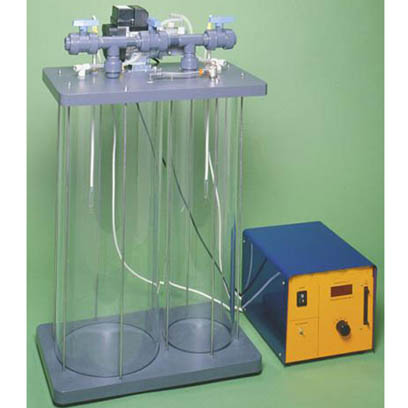

Water Hammer And Pipe Surge Apparatus

Categories: Thermodynamic LaboratoryDescription The equipment is free-standing and comprises two stainless steel test pipes connected to a constant head tank with the necessary connections to Hydraulics Bench. Pipe surge demonstration...

Product

Description

Description The equipment is free-standing and comprises two stainless steel test pipes connected to a constant head tank with the necessary connections to Hydraulics Bench. Pipe surge demonstrations are conducted using the first test pipe which incorporates a transparent surge shaft with scale and lever-operated valve at the discharge end. An additional valve downstream allows the flow through the test pipe to be varied before closing the lever operated valve. An electronic pressure sensor located at the base of the surge shaft allows the low-speed transients in water level to be measured. Water hammer demonstrations are conducted using the second test pipe, which incorporates a fast acting valve at the discharge end. An additional valve downstream allows the flow through the test pipe to be varied before closing the fast acting valve. The unique fast acting valve, allows water hammer to be generated in a relatively short length of straight pipe because of the extremely short closure time achieved using a trigger actuator. Tappings incorporating electronic pressure sensors are located in the test pipe adjacent to the fast acting valve and halfway along the test pipe. These sensors measure the high-speed pressure transients inside the pipe as the water hammer travels backward and forward along the test pipe. The time delay between the sensors can be used to determine the speed of sound through the water that is attenuated by the elasticity of the metal pipe wall. All three pressure sensors are connected to a conditioning unit with USB connection for direct connection to a PC (not supplied). The pressure sensors are connected to a conditioning unit with USB connection for direct connection to a PC. The transient pressure waves can be analysed on the PC (not supplied) using the software supplied. The pressure sensors are powered from the USB port on the PC so no additional power supply is necessary. Specification A freestanding unit designed to demonstrate the phenomena of pipe surge and water hammer when connected to a Hydraulics Bench Includes two separate stainless steel test pipes, both 3m long, constant head tank, slow acting valve, fast acting valve etc A transparent surge shaft (40 mm diameter and 800mm high) with scale allows transient water levels to be observed and timed Electronic sensors used to measure pressure transients at two locations in the water hammer test pipe, one adjacent to fast acting valve and one half way along the test pipe Pressure transients monitored using a PC (not supplied) using a USB connection from the pressure transducers (requires no external electrical supply) Straight metal pipes used, rather than a coiled arrangement, to minimize distortion to the pressure profile

quick overview :

Description The equipment is free-standing and comprises two stainless steel test pipes connected to a constant head tank with the necessary connections to Hydraulics Bench. Pipe surge demonstrations are conducted using the first test pipe which incorporates a transparent surge shaft with scale and lever-operated valve at the discharge end. An additional valve downstream allows the flow through the test pipe to be varied before closing the lever operated valve. An electronic pressure sensor located at the base of the surge shaft allows the low-speed transients in water level to be measured. Water hammer demonstrations are conducted using the second test pipe, which incorporates a fast acting valve at the discharge end. An additional valve downstream allows the flow through the test pipe to be varied before closing the fast acting valve. The unique fast acting valve, allows water hammer to be generated in a relatively short length of straight pipe because of the extremely short closure time achieved using a trigger actuator. Tappings incorporating electronic pressure sensors are located in the test pipe adjacent to the fast acting valve and halfway along the test pipe. These sensors measure the high-speed pressure transients inside the pipe as the water hammer travels backward and forward along the test pipe. The time delay between the sensors can be used to determine the speed of sound through the water that is attenuated by the elasticity of the metal pipe wall. All three pressure sensors are connected to a conditioning unit with USB connection for direct connection to a PC (not supplied). The pressure sensors are connected to a conditioning unit with USB connection for direct connection to a PC. The transient pressure waves can be analysed on the PC (not supplied) using the software supplied. The pressure sensors are powered from the USB port on the PC so no additional power supply is necessary. Specification A freestanding unit designed to demonstrate the phenomena of pipe surge and water hammer when connected to a Hydraulics Bench Includes two separate stainless steel test pipes, both 3m long, constant head tank, slow acting valve, fast acting valve etc A transparent surge shaft (40 mm diameter and 800mm high) with scale allows transient water levels to be observed and timed Electronic sensors used to measure pressure transients at two locations in the water hammer test pipe, one adjacent to fast acting valve and one half way along the test pipe Pressure transients monitored using a PC (not supplied) using a USB connection from the pressure transducers (requires no external electrical supply) Straight metal pipes used, rather than a coiled arrangement, to minimize distortion to the pressure profile

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.