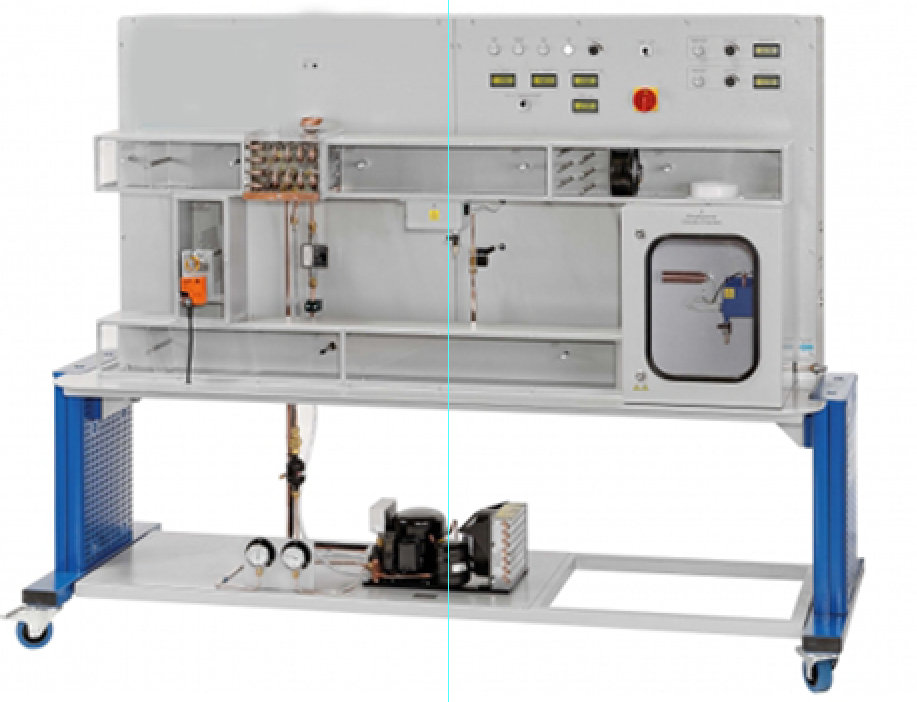

Air Conditioning System Model

Categories: Engineering Lab EquipmentAir conditioning technology is a key topic in building services engineering. For this reason air conditioning technology plays an important role during the training of skilled workers and engineers....

Product

Description

Air conditioning technology is a key topic in building

services engineering. For this reason air conditioning technology plays an

important role during the training of skilled workers and engineers.

The clear trainer represents a complete air conditioning

system with an air duct and a climatic chamber. The main components of the air

conditioning system are the air cooler with condensing unit, fan, steam

humidifier and air heater. Three motorised ventilation flaps control the air

distribution in the air conditioning system. The climatic chamber is equipped

with two different heat sources (wet and dry). Temperature and relative

humidity are measured at relevant points in the air duct and displayed

digitally. For the refrigeration circuit two manometers with integrated

temperature scale and a flow meter provide all relevant measurements.

Learning Objectives/Experiments

Air conditioning system and its components

Conditioning room air

Mixing different air flows

Representation in the h-x diagram for humid air

Humidification and dehumidification

Heating and cooling

Representation of the circuit in the log p-h diagram

Effect of a cooling load (dry and wet)

Recirculating and outer air operation

In conjunction with optional accessories

Automation in an air conditioning system

Specification

Model of an air conditioning system with outer air and

recirculating operation

Air duct with transparent front

Air duct with fan, air cooler, humidifier, flaps, air heater

and sensors

Chamber with wet (latent) and dry (sensitive) heat source as

cooling load

Motorised flaps for recirculating and outer air operation

Process schematic with signal lamps

Air conditioning system ready for different automation

solutions: 4 data cable connections to integrate the accessories

Technical Data

Compressor (air-cooled condensing unit)

power consumption: 159W at 7,2/54,4°C

refrigeration capacity: 380W at 7,2/54,4°C

Humidifier

heating power: 400W

Air heater

heating power: 360W

2 heaters in the chamber as cooling load

power output: 0…250W each, freely adjustable

Flow cross-section of the air duct

WxH: 155x155mm

Refrigerant: R513A, GWP: 631

filling volume: 1,2kg

CO2-equivalent: 0,8t

Measuring ranges

temperature: 0…50°C

rel. humidity: 10…90%

power consumption: 0…600W (condensing unit)

power: 2x 0…300W (cooling load)

pressure: -1…9bar / -1…24bar (refrigerant)

flow rate: 1,5…23,5L/h (refrigerant)

air velocity: 0…2,5m/s

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

230V, 60Hz, 3 phases

quick overview :

Air conditioning technology is a key topic in building

services engineering. For this reason air conditioning technology plays an

important role during the training of skilled workers and engineers.

The clear trainer represents a complete air conditioning

system with an air duct and a climatic chamber. The main components of the air

conditioning system are the air cooler with condensing unit, fan, steam

humidifier and air heater. Three motorised ventilation flaps control the air

distribution in the air conditioning system. The climatic chamber is equipped

with two different heat sources (wet and dry). Temperature and relative

humidity are measured at relevant points in the air duct and displayed

digitally. For the refrigeration circuit two manometers with integrated

temperature scale and a flow meter provide all relevant measurements.

Learning Objectives/Experiments

Air conditioning system and its components

Conditioning room air

Mixing different air flows

Representation in the h-x diagram for humid air

Humidification and dehumidification

Heating and cooling

Representation of the circuit in the log p-h diagram

Effect of a cooling load (dry and wet)

Recirculating and outer air operation

In conjunction with optional accessories

Automation in an air conditioning system

Specification

Model of an air conditioning system with outer air and

recirculating operation

Air duct with transparent front

Air duct with fan, air cooler, humidifier, flaps, air heater

and sensors

Chamber with wet (latent) and dry (sensitive) heat source as

cooling load

Motorised flaps for recirculating and outer air operation

Process schematic with signal lamps

Air conditioning system ready for different automation

solutions: 4 data cable connections to integrate the accessories

Technical Data

Compressor (air-cooled condensing unit)

power consumption: 159W at 7,2/54,4°C

refrigeration capacity: 380W at 7,2/54,4°C

Humidifier

heating power: 400W

Air heater

heating power: 360W

2 heaters in the chamber as cooling load

power output: 0…250W each, freely adjustable

Flow cross-section of the air duct

WxH: 155x155mm

Refrigerant: R513A, GWP: 631

filling volume: 1,2kg

CO2-equivalent: 0,8t

Measuring ranges

temperature: 0…50°C

rel. humidity: 10…90%

power consumption: 0…600W (condensing unit)

power: 2x 0…300W (cooling load)

pressure: -1…9bar / -1…24bar (refrigerant)

flow rate: 1,5…23,5L/h (refrigerant)

air velocity: 0…2,5m/s

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

230V, 60Hz, 3 phases

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.