Capacity Control and Faults In Refrigeration Systems

Categories: Engineering Lab EquipmentThe efficient control of the capacity and temperature in refrigeration systems is an important topic in refrigeration technology. With different methods of capacity control can be investigated. The c...

Product

Description

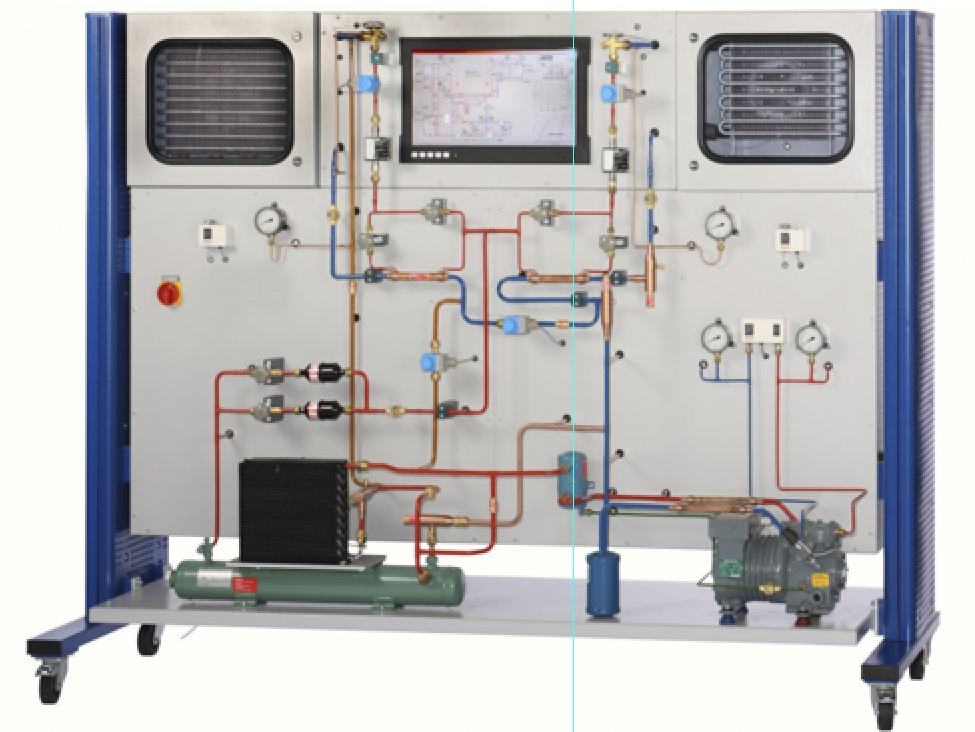

The efficient control of the capacity and temperature in

refrigeration systems is an important topic in refrigeration technology. With

different methods of capacity control can be investigated.

The components of a refrigeration circuit with refrigeration

and freezing chambers are arranged clearly in the trainer. Solenoid valves

enable the separate or parallel operation of the evaporators in the two

chambers. The circuit is equipped with a capacity controller, a start-up

controller and a combined pressures switch for the delivery and intake sides of

the compressor. One heat exchanger each in the inlet of the two evaporators

enables the supercooling of the refrigerant to be investigated for the

efficiency of the process. The refrigeration capacity of the two individual

chambers is controlled by a thermostat. The refrigeration chamber also features

an evaporation pressure controller.

Learning Objectives/Experiments

Familiarisation with the key devices for changing the

refrigeration capacity

Thermostat

Capacity controller

Start-up controller

Evaporation pressure controller

Condensation pressure controller

Fault finding in refrigeration system components

Effect of refrigerant supercooling

Familiarisation with defrosting methods

Electric defrost heater

Hot gas defrosting

Representation of the thermodynamic cycle in the log p-h

diagram

Specification

Investigation of a refrigeration system with refrigeration

and freezing chambers

Refrigeration circuit with compressor, condenser, capacity

controller, start-up controller, combined pressure switch and 2 evaporators in

insulated chambers

Each chamber with solenoid valve, thermostat, thermostatic

expansion valve, fan and heat exchanger for refrigerant supercooling

Refrigeration chamber with evaporation pressure controller

Freezing chamber with electric defrost heater and hot gas

defrosting

Separate or parallel operation of the chambers via solenoid

valves

Simulation of 12 faults

Touch panel PC for fault activation, data acquisition,

evaluation and representation in the log p-h diagram

Technical Data

Compressor

refrigeration capacity: 1640W at -10/50°C

power consumption: 980W at -10/50°C

Condenser with fan

volumetric air flow rate: 570m3/h

Evaporator transfer areas

refrigeration chamber: 1,12m2

freezing chamber: 1,88m2

Electric defrost heater: approx. 125W

Capacity controller: 0,2…6bar

Start-up controller: 0,2…6bar

Thermostat: 2x -25…15°C

Evaporation pressure controller: 0…5,5bar

Refrigerant

R449A

GWP: 1397

filling volume: 3,21kg

CO2-equivalent: 4,5t

Measuring ranges

temperature: 6x -50…50°C; 5x 0…100°C

pressure: 3x -1…15bar; 2x -1…24bar

flow rate: 2x 2…29L/h

power consumption: 0…5kW (compressor)

400V, 50Hz, 3 phases

230V, 60Hz, 3 phases; 400V, 60Hz, 3 phases

quick overview :

The efficient control of the capacity and temperature in

refrigeration systems is an important topic in refrigeration technology. With

different methods of capacity control can be investigated.

The components of a refrigeration circuit with refrigeration

and freezing chambers are arranged clearly in the trainer. Solenoid valves

enable the separate or parallel operation of the evaporators in the two

chambers. The circuit is equipped with a capacity controller, a start-up

controller and a combined pressures switch for the delivery and intake sides of

the compressor. One heat exchanger each in the inlet of the two evaporators

enables the supercooling of the refrigerant to be investigated for the

efficiency of the process. The refrigeration capacity of the two individual

chambers is controlled by a thermostat. The refrigeration chamber also features

an evaporation pressure controller.

Learning Objectives/Experiments

Familiarisation with the key devices for changing the

refrigeration capacity

Thermostat

Capacity controller

Start-up controller

Evaporation pressure controller

Condensation pressure controller

Fault finding in refrigeration system components

Effect of refrigerant supercooling

Familiarisation with defrosting methods

Electric defrost heater

Hot gas defrosting

Representation of the thermodynamic cycle in the log p-h

diagram

Specification

Investigation of a refrigeration system with refrigeration

and freezing chambers

Refrigeration circuit with compressor, condenser, capacity

controller, start-up controller, combined pressure switch and 2 evaporators in

insulated chambers

Each chamber with solenoid valve, thermostat, thermostatic

expansion valve, fan and heat exchanger for refrigerant supercooling

Refrigeration chamber with evaporation pressure controller

Freezing chamber with electric defrost heater and hot gas

defrosting

Separate or parallel operation of the chambers via solenoid

valves

Simulation of 12 faults

Touch panel PC for fault activation, data acquisition,

evaluation and representation in the log p-h diagram

Technical Data

Compressor

refrigeration capacity: 1640W at -10/50°C

power consumption: 980W at -10/50°C

Condenser with fan

volumetric air flow rate: 570m3/h

Evaporator transfer areas

refrigeration chamber: 1,12m2

freezing chamber: 1,88m2

Electric defrost heater: approx. 125W

Capacity controller: 0,2…6bar

Start-up controller: 0,2…6bar

Thermostat: 2x -25…15°C

Evaporation pressure controller: 0…5,5bar

Refrigerant

R449A

GWP: 1397

filling volume: 3,21kg

CO2-equivalent: 4,5t

Measuring ranges

temperature: 6x -50…50°C; 5x 0…100°C

pressure: 3x -1…15bar; 2x -1…24bar

flow rate: 2x 2…29L/h

power consumption: 0…5kW (compressor)

400V, 50Hz, 3 phases

230V, 60Hz, 3 phases; 400V, 60Hz, 3 phases

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.