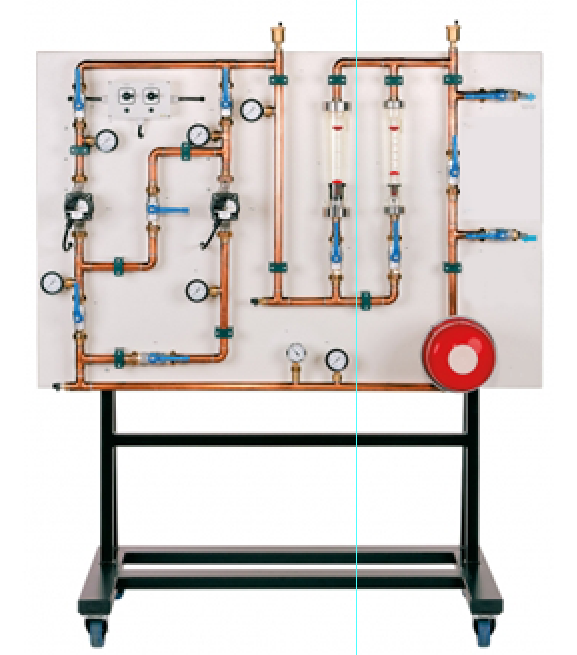

Circulating Pumps Training Panel

Categories: Engineering Lab EquipmentThe trainer contains a pipe system with two circulating pumps. It is possible to switch between series and parallel operation using ball valves. Two rotameters with different measuring ranges are pro...

Product

Description

The trainer contains a pipe system with two circulating

pumps. It is possible to switch between series and parallel operation using

ball valves.

Two rotameters with different measuring ranges are provided

for the measurement of the flow rate. Manometers indicate the pressure at all

relevant points in the system. The temperature can be read on a bimetallic

thermometer.

The trainer has a closed water circuit with expansion vessel

and is thus independent of the water mains.

Learning Objectives/Experiments

Pump characteristics at varying speeds

Determination of pipework characteristics and operating

points

Series operation of circulating pumps

Parallel operation of circulating pumps

Comparison of experiment and calculation

In conjunction with other training panels in the series, it

is possible to set up a complete heating system.

Specification

Series and parallel operation of 2 pumps

Training panel can be changed to various operating modes

using ball valves

2 rotameters

Pressure measurement with 6 Bourdon tube manometers

1 bimetallic thermometer

Water connections made using quick-release couplings

Technical Data

2 pumps

power consumption: 70W

max. flow rate: 60L/min

max. head: 4m

Measuring ranges

flow rate:

1x 150…1600L/h

1x 400…4000L/h

temperature: 0…60°C

pressure: 0…2,5bar

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

quick overview :

The trainer contains a pipe system with two circulating

pumps. It is possible to switch between series and parallel operation using

ball valves.

Two rotameters with different measuring ranges are provided

for the measurement of the flow rate. Manometers indicate the pressure at all

relevant points in the system. The temperature can be read on a bimetallic

thermometer.

The trainer has a closed water circuit with expansion vessel

and is thus independent of the water mains.

Learning Objectives/Experiments

Pump characteristics at varying speeds

Determination of pipework characteristics and operating

points

Series operation of circulating pumps

Parallel operation of circulating pumps

Comparison of experiment and calculation

In conjunction with other training panels in the series, it

is possible to set up a complete heating system.

Specification

Series and parallel operation of 2 pumps

Training panel can be changed to various operating modes

using ball valves

2 rotameters

Pressure measurement with 6 Bourdon tube manometers

1 bimetallic thermometer

Water connections made using quick-release couplings

Technical Data

2 pumps

power consumption: 70W

max. flow rate: 60L/min

max. head: 4m

Measuring ranges

flow rate:

1x 150…1600L/h

1x 400…4000L/h

temperature: 0…60°C

pressure: 0…2,5bar

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.