Comparison of Various Heat Exchangers

Categories: Engineering Lab EquipmentIn practice, different types of heat exchanger are used depending on requirements in order to ensure efficient heat transfer and avoid losses.The trainer is used to study and compare five different he...

Product

Description

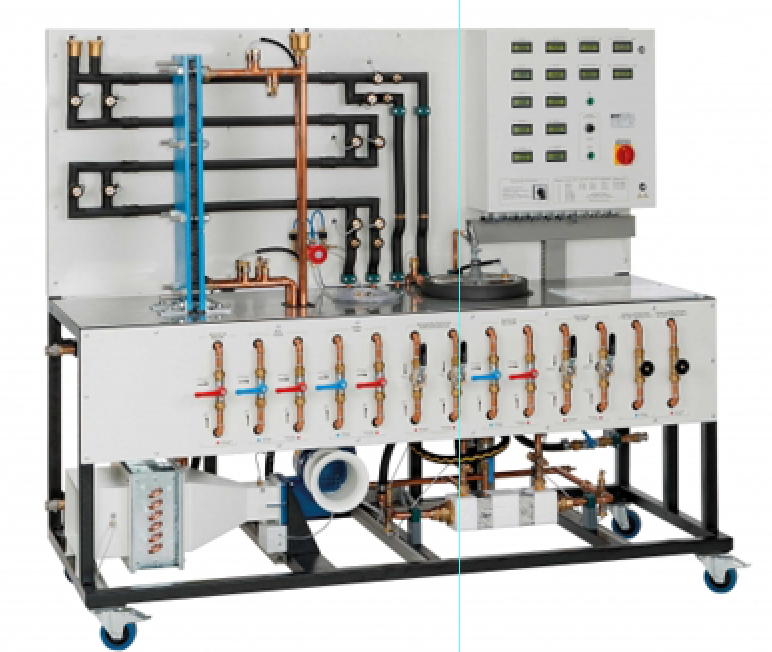

In practice, different types of heat exchanger are used depending on requirements in order to ensure efficient heat transfer and avoid losses.

The trainer is used to study and compare five different heat exchangers. Both parallel flow and counterflow operation are demonstrated, with their different temperature curves.

In the plate, tubular and shell & tube heat exchangers, heat is transferred between hot and cold water in tubes or between plates. In the finned tube heat exchanger, the air flows around pipes with hot water in crossflow.

In the stirred tank with double jacket and coiled tube, either the outer jacket or the inner coiled tube can be filled with hot water. A stirring machine ensures that the water inside the tank is mixed to achieve an even heat distribution.

Learning Objectives/Experiments

Familiarisation with heat transfer processes

Heat transfer

Heat conduction

Determination of the heat transfer coefficient

Creation of temperature curves for the different heat exchangers

Parallel flow

Counterflow

Cross parallel flow

Cross counterflow

Comparison of the different heat exchangers between each other

Plate heat exchanger

Tubular heat exchanger

Shell & tube heat exchanger

Finned tube heat exchanger

Stirred tank with double jacket and coiled tube

Specification

Investigation and comparison of five different heat exchanger types

Parallel flow or counterflow can be set via valves

Flow rates can be adjusted via valves

Electromagnetic flow meter for hot and cold water

Portable differential pressure sensor for water

Fixed differential pressure sensor for air, to determine the volumetric flow rate

Digital displays for temperature, pressure differences and flow rate

Hot water generator and water chiller available

Technical Data

Plate heat exchanger, (water-water)

number of plates: 10

heat transfer area: approx. 0,26m2

output: 15kW

Tubular heat exchanger (water-water)

heat transfer area: 0,1m2

Shell & tube heat exchanger (water-water)

output: 13kW

Finned tube heat exchanger (water-air)

heat transfer area: approx. 2,8m2

fan max. flow rate: 780m3/h

fan max. pressure difference: 430Pa

Stirred tank with double jacket and coiled tube (water-water)

double jacket heat transfer area: 0,16m2

coiled tube heat transfer area: 0,17m2

Measuring ranges

differential pressure:

1x 0…10mbar (air)

1x 0…1000mbar (water)

flow rate: 2x 0…3m3/h

temperature: 10x 0…100°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

quick overview :

In practice, different types of heat exchanger are used depending on requirements in order to ensure efficient heat transfer and avoid losses.

The trainer is used to study and compare five different heat exchangers. Both parallel flow and counterflow operation are demonstrated, with their different temperature curves.

In the plate, tubular and shell & tube heat exchangers, heat is transferred between hot and cold water in tubes or between plates. In the finned tube heat exchanger, the air flows around pipes with hot water in crossflow.

In the stirred tank with double jacket and coiled tube, either the outer jacket or the inner coiled tube can be filled with hot water. A stirring machine ensures that the water inside the tank is mixed to achieve an even heat distribution.

Learning Objectives/Experiments

Familiarisation with heat transfer processes

Heat transfer

Heat conduction

Determination of the heat transfer coefficient

Creation of temperature curves for the different heat exchangers

Parallel flow

Counterflow

Cross parallel flow

Cross counterflow

Comparison of the different heat exchangers between each other

Plate heat exchanger

Tubular heat exchanger

Shell & tube heat exchanger

Finned tube heat exchanger

Stirred tank with double jacket and coiled tube

Specification

Investigation and comparison of five different heat exchanger types

Parallel flow or counterflow can be set via valves

Flow rates can be adjusted via valves

Electromagnetic flow meter for hot and cold water

Portable differential pressure sensor for water

Fixed differential pressure sensor for air, to determine the volumetric flow rate

Digital displays for temperature, pressure differences and flow rate

Hot water generator and water chiller available

Technical Data

Plate heat exchanger, (water-water)

number of plates: 10

heat transfer area: approx. 0,26m2

output: 15kW

Tubular heat exchanger (water-water)

heat transfer area: 0,1m2

Shell & tube heat exchanger (water-water)

output: 13kW

Finned tube heat exchanger (water-air)

heat transfer area: approx. 2,8m2

fan max. flow rate: 780m3/h

fan max. pressure difference: 430Pa

Stirred tank with double jacket and coiled tube (water-water)

double jacket heat transfer area: 0,16m2

coiled tube heat transfer area: 0,17m2

Measuring ranges

differential pressure:

1x 0…10mbar (air)

1x 0…1000mbar (water)

flow rate: 2x 0…3m3/h

temperature: 10x 0…100°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.