Electrical Installation In Refrigeration Systems

Categories: Engineering Lab EquipmentThe wiring of electrical components is a typical task in the field of refrigeration. Besides the design and operation of the individual components, knowledge about the interaction of the components in...

Product

Description

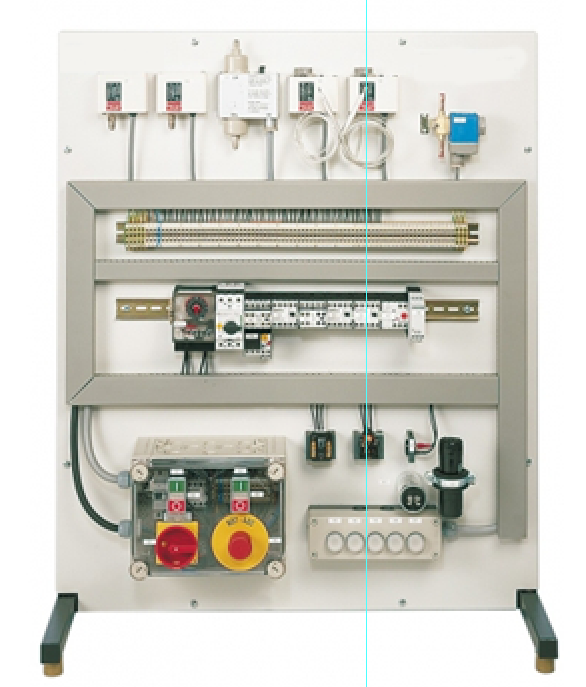

The wiring of electrical components is a typical task in the

field of refrigeration. Besides the design and operation of the individual

components, knowledge about the interaction of the components in circuits is an

important learning objective. Safety aspects also play an important role. With

this knowledge and these skills can be acquired.

The electrical components are arranged clearly visible. All

components are connected on terminal blocks. Using the cables included in the

scope of delivery it is possible to set up different circuits correctly and

operationally. Lamps simulate the consumers. All components are operated and

tested with mains voltage to provide high relevance for practice.

Learning Objectives/Experiments

Read, understand, wire and test electric circuit diagrams

Design and operation of electrical components from

refrigeration

Start-up capacitor

Operating capacitor

Start-up relay

Time relay

Timer

Circuit breaker

Start-up current limiter

Contactors

Pressure switch

Thermostat

Solenoid valve

Design and testing of a safety chain

Star / delta connection

Change of direction of rotation in an alternating current

circuit

Safety aspects when handling mains voltage

Specification

Experimental unit from the practical series for the training

of mechatronics engineers for refrigeration

Design and investigation of circuits with electrical

components from refrigeration

Electrical components mounted clearly visible and connected

on terminal blocks

1 set of cables with wire end ferrules for wiring electrical

components on terminal blocks

3 pressure switches, 2 thermostats, 1 solenoid valve, 1

timer, 4 circuit breakers, 5 contactors, 3 relays, 2 capacitors

5 lamps to simulate consumers

Technical Data

3 pressure switches

high pressure: 8…32bar

low pressure: -0,9…7bar

differential pressure: 0,3…4,5bar

2 thermostats: -5…20°C

1 timer

2 switchable outputs

switching time: 1…60min

4 circuit breakers

bimetallic circuit breaker

thermistor circuit breaker

circuit breaker with start-up current limiter

adjustable protection relay

5 contactors

2x: 3 NO, 1 NC

3x: 4 NO

3 relays

electromagnetic start-up relay

PTC start-up relay

time relay

Start-up and operating capacitor: 15µF, 80µF

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases; 230V, 60Hz, 3 phases

quick overview :

The wiring of electrical components is a typical task in the

field of refrigeration. Besides the design and operation of the individual

components, knowledge about the interaction of the components in circuits is an

important learning objective. Safety aspects also play an important role. With

this knowledge and these skills can be acquired.

The electrical components are arranged clearly visible. All

components are connected on terminal blocks. Using the cables included in the

scope of delivery it is possible to set up different circuits correctly and

operationally. Lamps simulate the consumers. All components are operated and

tested with mains voltage to provide high relevance for practice.

Learning Objectives/Experiments

Read, understand, wire and test electric circuit diagrams

Design and operation of electrical components from

refrigeration

Start-up capacitor

Operating capacitor

Start-up relay

Time relay

Timer

Circuit breaker

Start-up current limiter

Contactors

Pressure switch

Thermostat

Solenoid valve

Design and testing of a safety chain

Star / delta connection

Change of direction of rotation in an alternating current

circuit

Safety aspects when handling mains voltage

Specification

Experimental unit from the practical series for the training

of mechatronics engineers for refrigeration

Design and investigation of circuits with electrical

components from refrigeration

Electrical components mounted clearly visible and connected

on terminal blocks

1 set of cables with wire end ferrules for wiring electrical

components on terminal blocks

3 pressure switches, 2 thermostats, 1 solenoid valve, 1

timer, 4 circuit breakers, 5 contactors, 3 relays, 2 capacitors

5 lamps to simulate consumers

Technical Data

3 pressure switches

high pressure: 8…32bar

low pressure: -0,9…7bar

differential pressure: 0,3…4,5bar

2 thermostats: -5…20°C

1 timer

2 switchable outputs

switching time: 1…60min

4 circuit breakers

bimetallic circuit breaker

thermistor circuit breaker

circuit breaker with start-up current limiter

adjustable protection relay

5 contactors

2x: 3 NO, 1 NC

3x: 4 NO

3 relays

electromagnetic start-up relay

PTC start-up relay

time relay

Start-up and operating capacitor: 15µF, 80µF

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases; 230V, 60Hz, 3 phases

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.