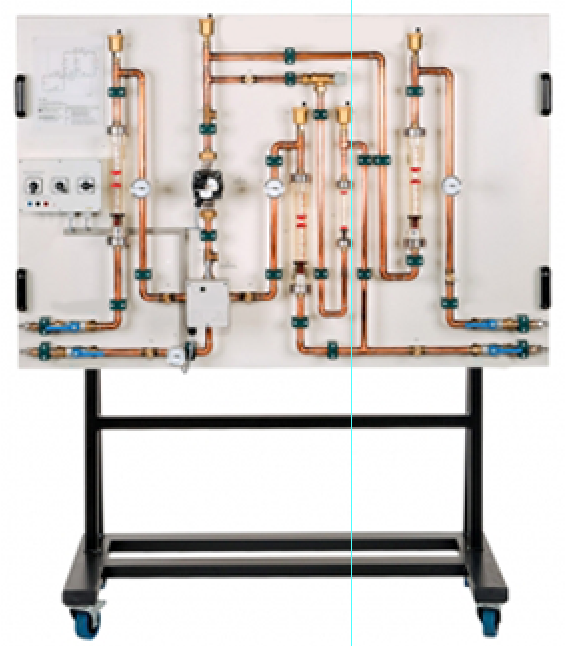

Four Way Mixing Valve Training Panel

Categories: Engineering Lab EquipmentThe trainer was designed for heating and plumbing trainees. The four-way mixing valve in a heating system controls the circulation and feed flow temperatures of the water flowing in the heating syste...

Product

Description

The trainer was designed for heating and plumbing trainees.

The four-way mixing valve in a heating system controls the

circulation and feed flow temperatures of the water flowing in the heating

system and the boiler return flow temperature. It is possible to add the hot

water required and to connect radiators. The differential pressure across the

pipe system is limited using a relief valve. Bimetallic thermometers indicate

relevant temperatures.

Learning Objectives/Experiments

Function and operating behaviour of a four-way mixing valve

Effect of the mixing ratio on feed and circulating flow

temperature

Effect of mixer setting on the flow rate

In conjunction with other trainers in the series, it is

possible to set up a complete heating system.

Specification

Trainer on heating systems and plumbing

4-way mixing valve DN 20

Circulating pump

4 rotameters

4 bimetallic thermometers

2 heating water connections DN 15

2 water connections for boiler DN 15

1 differential pressure overflow valve

Water connections made using quick-release couplings

Technical Data

Pump

power consumption: 60W

max. flow rate: 60L/min

max. head: 4m

Four-way mixing valve

setting angle: 90°

opening time: 2min

Measuring ranges

flow rate:

3x 150…1600L/h

1x 0…440L/h

temperature: 0…100°C

230V, 50Hz, 1 phase

quick overview :

The trainer was designed for heating and plumbing trainees.

The four-way mixing valve in a heating system controls the

circulation and feed flow temperatures of the water flowing in the heating

system and the boiler return flow temperature. It is possible to add the hot

water required and to connect radiators. The differential pressure across the

pipe system is limited using a relief valve. Bimetallic thermometers indicate

relevant temperatures.

Learning Objectives/Experiments

Function and operating behaviour of a four-way mixing valve

Effect of the mixing ratio on feed and circulating flow

temperature

Effect of mixer setting on the flow rate

In conjunction with other trainers in the series, it is

possible to set up a complete heating system.

Specification

Trainer on heating systems and plumbing

4-way mixing valve DN 20

Circulating pump

4 rotameters

4 bimetallic thermometers

2 heating water connections DN 15

2 water connections for boiler DN 15

1 differential pressure overflow valve

Water connections made using quick-release couplings

Technical Data

Pump

power consumption: 60W

max. flow rate: 60L/min

max. head: 4m

Four-way mixing valve

setting angle: 90°

opening time: 2min

Measuring ranges

flow rate:

3x 150…1600L/h

1x 0…440L/h

temperature: 0…100°C

230V, 50Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.