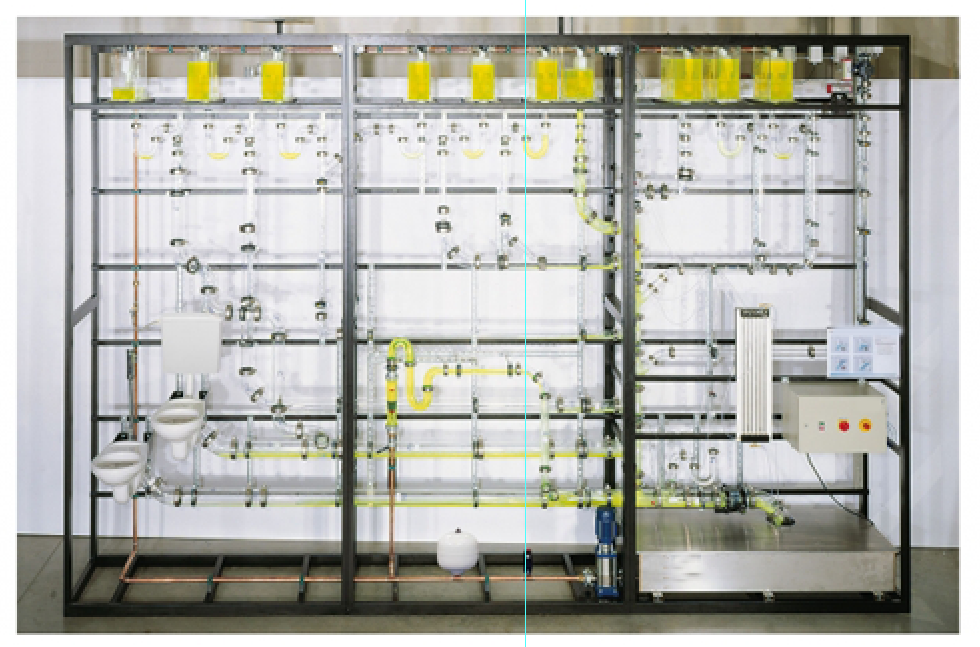

Full Scale Sewerage System

Categories: Engineering Lab EquipmentThe routing of sewers is particularly important in wastewater engineering. Pipe inclinations, pipe inlets and outlet, reducers and cross-sections must be considered when designing systems, taking into...

Product

Description

The routing of sewers is particularly important in wastewater engineering. Pipe inclinations, pipe inlets and outlet, reducers and cross-sections must be considered when designing systems, taking into account interactions between the components. In particular, the pressure distribution in complex pipe systems places high demands on design engineers. Design errors lead to noise, empty drain traps and clogged pipes.

It allows a variety of experiments in the field of wastewater engineering and enables the visualisation of flow processes in sewers.

The experimental plant includes an extensive drainage pipe system based on common real-world elements. The pipes are transparent to allow visualisation of the flow processes. The cisterns are located in the top part of the experimental plant. These are opened or closed individually via solenoid valves. In addition, the bypass, ventilation pipe and pressure flushing are equipped with solenoid valves. The solenoid valves are triggered via a remote control. The system can be used to study the flow and pressure curve at different types of junctions, pipe offsets, cross-sectional changes and drain traps under different ventilation and evacuation conditions. The system contains a closed water circuit with collection tank and pump.

Learning Objectives/Experiments

Pressure curve in the downcomer

Bypass

Incorrect flow behaviour with defective ventilation of the pipes

Incorrect flow behaviour with incorrect pipe sizing

Flow at pipe offset

Suction effect at junctions

Behaviour of sanitary valves and fittings

Function of various drainage pipes

Specification

Pressure curve in the downcomer

Bypass

Incorrect flow behaviour with defective ventilation of the pipes

Incorrect flow behaviour with incorrect pipe sizing

Flow at pipe offset

Suction effect at junctions

Behaviour of sanitary valves and fittings

Function of various drainage pipes

Technical data

Pump

power consumption: 550W

max. flow rate: 4,5m3/h

max. head: 42,6m

Collection tank

volume: approx. 300L

Transparent cisterns

4x 20L

6x 10L

Cistern

1x 9L

Flush for toilet: max. 9L

Measuring ranges

flow rate: 0,4…4L/h

pressure: 6x 1500mmWC

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

UL/CSA optional

Dimensions and weight

LxWxH: 5700x800x3900mm

Weight: approx. 1100kg

quick overview :

The routing of sewers is particularly important in wastewater engineering. Pipe inclinations, pipe inlets and outlet, reducers and cross-sections must be considered when designing systems, taking into account interactions between the components. In particular, the pressure distribution in complex pipe systems places high demands on design engineers. Design errors lead to noise, empty drain traps and clogged pipes.

It allows a variety of experiments in the field of wastewater engineering and enables the visualisation of flow processes in sewers.

The experimental plant includes an extensive drainage pipe system based on common real-world elements. The pipes are transparent to allow visualisation of the flow processes. The cisterns are located in the top part of the experimental plant. These are opened or closed individually via solenoid valves. In addition, the bypass, ventilation pipe and pressure flushing are equipped with solenoid valves. The solenoid valves are triggered via a remote control. The system can be used to study the flow and pressure curve at different types of junctions, pipe offsets, cross-sectional changes and drain traps under different ventilation and evacuation conditions. The system contains a closed water circuit with collection tank and pump.

Learning Objectives/Experiments

Pressure curve in the downcomer

Bypass

Incorrect flow behaviour with defective ventilation of the pipes

Incorrect flow behaviour with incorrect pipe sizing

Flow at pipe offset

Suction effect at junctions

Behaviour of sanitary valves and fittings

Function of various drainage pipes

Specification

Pressure curve in the downcomer

Bypass

Incorrect flow behaviour with defective ventilation of the pipes

Incorrect flow behaviour with incorrect pipe sizing

Flow at pipe offset

Suction effect at junctions

Behaviour of sanitary valves and fittings

Function of various drainage pipes

Technical data

Pump

power consumption: 550W

max. flow rate: 4,5m3/h

max. head: 42,6m

Collection tank

volume: approx. 300L

Transparent cisterns

4x 20L

6x 10L

Cistern

1x 9L

Flush for toilet: max. 9L

Measuring ranges

flow rate: 0,4…4L/h

pressure: 6x 1500mmWC

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

UL/CSA optional

Dimensions and weight

LxWxH: 5700x800x3900mm

Weight: approx. 1100kg

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.