Hydronic Balancing of Radiators

Categories: Engineering Lab EquipmentHydronic balancing is used to limit the amount of water which is calculated for each radiator. Balancing ensures that all radiators can be supplied with hot water at all operating points according to...

Product

Description

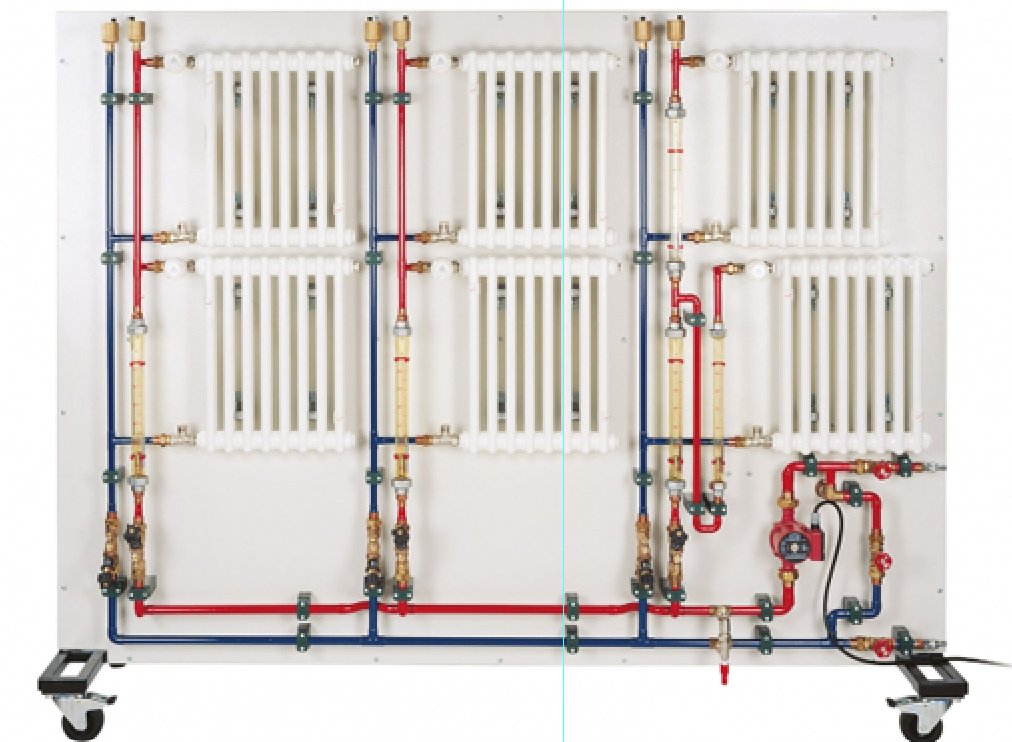

Hydronic balancing is used to limit the amount of water which is calculated for each radiator. Balancing ensures that all radiators can be supplied with hot water at all operating points according to their thermal requirement. The balancing is performed using adjustable lockshield valves. The trainer uses commercially available components to implement three heating subcircuits with radiators, thermostatic valves and a circulating pump. All three subcircuits can be shut-off individually. Once filled, the system is independent of the water mains or feed flow and return flow pipe connections. However, it can be operated in conjunction with a heating circuit.

Learning Objectives/Experiments

Variable pipework resistance

Balancing valve

Preset thermostatic valve

Differential pressure relief valve

Features

Balancing of a heating system

Water connections made using quick-release couplings

Specification

Trainer for heating and plumbing

6 radiators with thermostatic valve, bleed valve and adjustable lockshield valve

Expansion vessel, safety group according to DIN 4751, overflow valve

5 rotameters

1 surface thermometer for temperature measurement at radiator inlets and outlets

Water connections using quick-release couplings, diameter inside 13mm, for optional connection to an external heating circuit

Technical Data

Pump

power consumption: 60W

max. flow rate: 60L/min

max. head: 4m

6 balancing valves: PN 16

Measuring ranges

flow rate: 1x 30…320L/h, 4x 50…640L/h

temperature: 1x -50…300°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

quick overview :

Hydronic balancing is used to limit the amount of water which is calculated for each radiator. Balancing ensures that all radiators can be supplied with hot water at all operating points according to their thermal requirement. The balancing is performed using adjustable lockshield valves. The trainer uses commercially available components to implement three heating subcircuits with radiators, thermostatic valves and a circulating pump. All three subcircuits can be shut-off individually. Once filled, the system is independent of the water mains or feed flow and return flow pipe connections. However, it can be operated in conjunction with a heating circuit.

Learning Objectives/Experiments

Variable pipework resistance

Balancing valve

Preset thermostatic valve

Differential pressure relief valve

Features

Balancing of a heating system

Water connections made using quick-release couplings

Specification

Trainer for heating and plumbing

6 radiators with thermostatic valve, bleed valve and adjustable lockshield valve

Expansion vessel, safety group according to DIN 4751, overflow valve

5 rotameters

1 surface thermometer for temperature measurement at radiator inlets and outlets

Water connections using quick-release couplings, diameter inside 13mm, for optional connection to an external heating circuit

Technical Data

Pump

power consumption: 60W

max. flow rate: 60L/min

max. head: 4m

6 balancing valves: PN 16

Measuring ranges

flow rate: 1x 30…320L/h, 4x 50…640L/h

temperature: 1x -50…300°C

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.