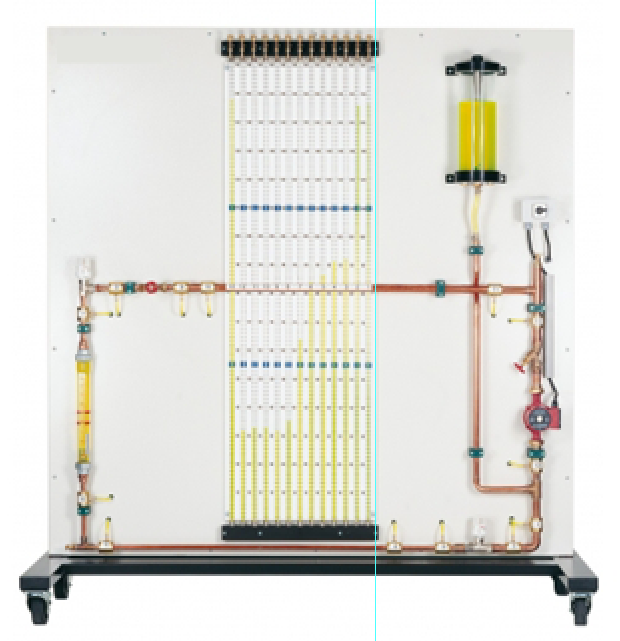

Installation Technology Losses In A Pipe System

Categories: Engineering Lab EquipmentWhen water flows through a pipe system there are resistances as a result of changes in direction, valves and fittings and pipe friction. The flow resistances are directly dependent on the geometry of...

Product

Description

When water flows through a pipe system there are resistances

as a result of changes in direction, valves and fittings and pipe friction. The

flow resistances are directly dependent on the geometry of the pipe elements

and the number and type of fittings. In addition, the flow velocity plays a key

role in the occurrence of pressure losses. The unit can be used to investigate

and visualise the pressure distribution in a pipe system. The trainer enables

the examination by experiment of different influencing factors on the pressure

losses in real pipe systems. The relationship between pump characteristic and

system characteristic is studied in the experiment. The pipe elements used are

commercially standard components in heating and sanitary engineering. The clear

panel is mounted on a sturdy, movable frame.

Learning Objectives/Experiments

Pressure curve in a closed pipe system with circulation pump

Influence of pipe diameter, flow velocity, change in

cross-section and pipe fittings on the pressure losses

Determination of pump characteristics, system

characteristics and the operating point

Specification

Investigation of the pressure losses at contractions, pipe

angles, pipe bends, valves and fittings and pipe elements of different diameter

Pipe elements are commercially standard components in

heating and sanitary engineering

Clear panel mounted on a sturdy, movable frame

Closed water circuit with pump and tank

Integrated bleed valve on manometer and in the pipe section

Flow measurement using rotameter

Measurement of the pressure distribution at 13 pressure

measuring points, display with 13 tube manometers

Technical Data

Pump

3 stages

max. flow rate: 4,5m³/h

max. head: 6m

Tank: approx. 5L

Measuring ranges

flow rate: 100…1000L/h

pressure: 1600mmWC

230V, 50Hz, 1 phase

quick overview :

When water flows through a pipe system there are resistances

as a result of changes in direction, valves and fittings and pipe friction. The

flow resistances are directly dependent on the geometry of the pipe elements

and the number and type of fittings. In addition, the flow velocity plays a key

role in the occurrence of pressure losses. The unit can be used to investigate

and visualise the pressure distribution in a pipe system. The trainer enables

the examination by experiment of different influencing factors on the pressure

losses in real pipe systems. The relationship between pump characteristic and

system characteristic is studied in the experiment. The pipe elements used are

commercially standard components in heating and sanitary engineering. The clear

panel is mounted on a sturdy, movable frame.

Learning Objectives/Experiments

Pressure curve in a closed pipe system with circulation pump

Influence of pipe diameter, flow velocity, change in

cross-section and pipe fittings on the pressure losses

Determination of pump characteristics, system

characteristics and the operating point

Specification

Investigation of the pressure losses at contractions, pipe

angles, pipe bends, valves and fittings and pipe elements of different diameter

Pipe elements are commercially standard components in

heating and sanitary engineering

Clear panel mounted on a sturdy, movable frame

Closed water circuit with pump and tank

Integrated bleed valve on manometer and in the pipe section

Flow measurement using rotameter

Measurement of the pressure distribution at 13 pressure

measuring points, display with 13 tube manometers

Technical Data

Pump

3 stages

max. flow rate: 4,5m³/h

max. head: 6m

Tank: approx. 5L

Measuring ranges

flow rate: 100…1000L/h

pressure: 1600mmWC

230V, 50Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.