Installation Technology Losses In Pipe Bends

Categories: Engineering Lab EquipmentIn addition to pressure losses due to pipe friction, pipes through which water flows experience pressure losses at changes in pipe direction. In practice, various changes in pipe direction with differ...

Product

Description

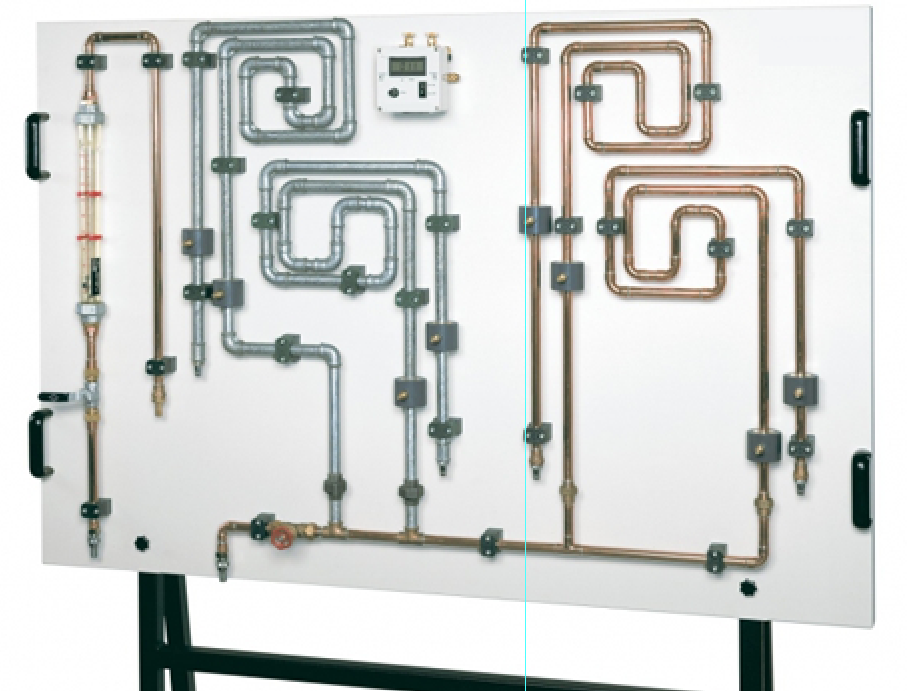

In addition to pressure losses due to pipe friction, pipes

through which water flows experience pressure losses at changes in pipe

direction. In practice, various changes in pipe direction with different

geometries are used in pipe networks. It can be used to investigate how

different changes in pipe direction made from different materials affect the

pipe flow. The pipe elements used are commercially standard components in

heating and sanitary engineering. The clear panel is mounted on a sturdy,

movable frame. The trainer consists of four pipe elements with ten deflections

each with the same pipe length. Two measuring sections have different radii and

are made of different materials. A hose connects the desired measuring section.

The flow is adjusted using valves in the inflow and return and read on a

rotameter.

Learning Objectives/Experiments

Flow measurement

Differential pressure measurement

Effect of flow and surface roughness

Effect of the flow velocity

Effect of changes in pipe direction

Specification

Investigation of the pressure loss at pipe elements with

different changes in pipe direction and materials

Pipe elements are commercially standard components in

heating and sanitary engineering

Clear panel mounted on a sturdy, movable frame

Simply selection of the measuring sections via hose

connection with quick-release couplings

Flow can be adjusted via valves

Flow measurement using rotameter

Differential pressure measurement via differential pressure

meter with display

Technical Data

Measuring sections, length: 2300mm

pipe section 1: steel, diameter: 1/2”, 90° pipe angle

pipe section 2: steel, diameter: 1/2”, 90° pipe bend

pipe section 3: copper, diameter: 18x1mm, 90° pipe angle

pipe section 4: copper, diameter: 18x1mm, 90° pipe bend

Measuring ranges

flow rate: 150…1600L/h

differential pressure: ±350mbar

quick overview :

In addition to pressure losses due to pipe friction, pipes

through which water flows experience pressure losses at changes in pipe

direction. In practice, various changes in pipe direction with different

geometries are used in pipe networks. It can be used to investigate how

different changes in pipe direction made from different materials affect the

pipe flow. The pipe elements used are commercially standard components in

heating and sanitary engineering. The clear panel is mounted on a sturdy,

movable frame. The trainer consists of four pipe elements with ten deflections

each with the same pipe length. Two measuring sections have different radii and

are made of different materials. A hose connects the desired measuring section.

The flow is adjusted using valves in the inflow and return and read on a

rotameter.

Learning Objectives/Experiments

Flow measurement

Differential pressure measurement

Effect of flow and surface roughness

Effect of the flow velocity

Effect of changes in pipe direction

Specification

Investigation of the pressure loss at pipe elements with

different changes in pipe direction and materials

Pipe elements are commercially standard components in

heating and sanitary engineering

Clear panel mounted on a sturdy, movable frame

Simply selection of the measuring sections via hose

connection with quick-release couplings

Flow can be adjusted via valves

Flow measurement using rotameter

Differential pressure measurement via differential pressure

meter with display

Technical Data

Measuring sections, length: 2300mm

pipe section 1: steel, diameter: 1/2”, 90° pipe angle

pipe section 2: steel, diameter: 1/2”, 90° pipe bend

pipe section 3: copper, diameter: 18x1mm, 90° pipe angle

pipe section 4: copper, diameter: 18x1mm, 90° pipe bend

Measuring ranges

flow rate: 150…1600L/h

differential pressure: ±350mbar

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.