Introduction To Refrigeration

Categories: Engineering Lab EquipmentWith simple and clear experiments this equipment is intended mainly as a basic introduction to refrigeration. It enables familiarisation with the operation and handling of a refrigeration system. The...

Product

Description

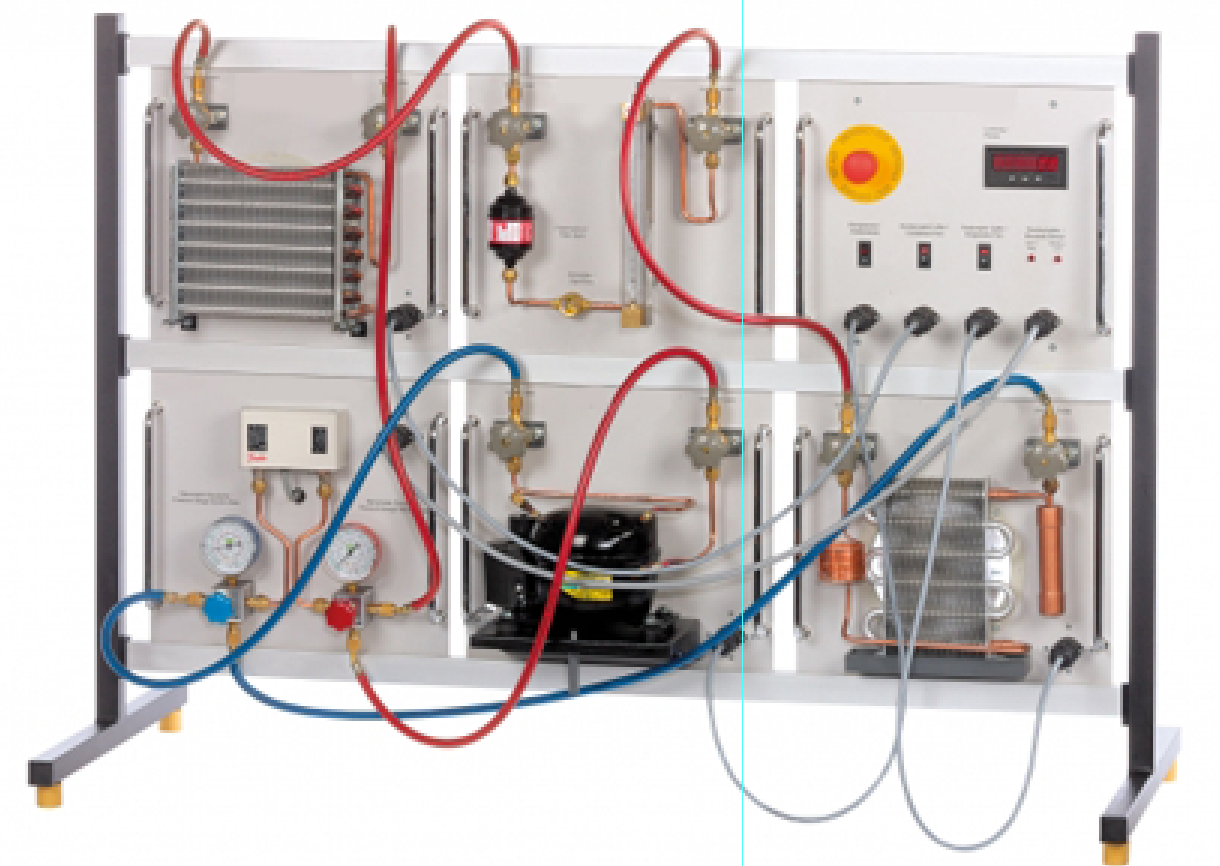

With simple and clear experiments this equipment is intended

mainly as a basic introduction to refrigeration. It enables familiarisation

with the operation and handling of a refrigeration system. The experimental

unit includes all the necessary components for a fully operational

refrigeration circuit, such as compressor, condenser, evaporator and a

capillary tube as expansion element. Other components complement the scope of

the equipment: display and control panel, pressure switches and pressure display

to protect the compressor against excessive pressure and a flow meter and sight

glass with filter/drier. Condenser and evaporator are each present twice: as

air/refrigerant heat exchanger and as water/refrigerant heat exchanger. This

allows for different component combinations. The components are mounted on

plates and form installation-ready modules. 6 of the 8 modules are positioned

in the frame at any one time and connected via hoses and supply cables. This

allows for the construction of different simple compression refrigeration

systems. For filling the system the refrigerant filling and evacuation

equipment is recommended.

Learning Objectives/Experiments

Fundamentals of a simple refrigeration circuit

Detection and understanding of the cyclic process

Changes of state of the refrigerant

Representation the refrigeration circuit in the process

schematic

Representation of the cyclic process in the log p-h diagram

Estimating key figures, refrigeration capacity and heat

fluxes

Different operating modes

Air cooling

Generating cold water

Heat pump (generate hot water)

Practical exercises

Draining and filling the refrigeration system

Fault finding

Specification

Setup of simple refrigeration circuits with different

components

8 self-contained operational modules mounted on a plate each

Light-weight aluminium frame to arrange 6 modules

Evaporator and condenser each available as air/refrigerant

heat exchanger (finned tube heat exchanger) and as water/refrigerant heat

exchanger (with pipe coil)

Modules fitted with manual valves

Components connected via hoses

Technical Data

Hermetic refrigerant compressor

power consumption: 67W at 5/40°C

refrigeration capacity: 152W at 5/40°C

Tank content

water tank, evaporator: 2L

water tank, condenser: 3L

Pressure switch activation pressure

LP: 1bar

HP: 14bar

Manometer

inlet side (low pressure): 1…10bar

outlet side (high pressure): 1…30bar

Rotameter: 0…7,4L/h

Refrigerant

R513A

GWP: 631

filling volume: 400g

CO2-equivalent: 0,3t

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

quick overview :

With simple and clear experiments this equipment is intended

mainly as a basic introduction to refrigeration. It enables familiarisation

with the operation and handling of a refrigeration system. The experimental

unit includes all the necessary components for a fully operational

refrigeration circuit, such as compressor, condenser, evaporator and a

capillary tube as expansion element. Other components complement the scope of

the equipment: display and control panel, pressure switches and pressure display

to protect the compressor against excessive pressure and a flow meter and sight

glass with filter/drier. Condenser and evaporator are each present twice: as

air/refrigerant heat exchanger and as water/refrigerant heat exchanger. This

allows for different component combinations. The components are mounted on

plates and form installation-ready modules. 6 of the 8 modules are positioned

in the frame at any one time and connected via hoses and supply cables. This

allows for the construction of different simple compression refrigeration

systems. For filling the system the refrigerant filling and evacuation

equipment is recommended.

Learning Objectives/Experiments

Fundamentals of a simple refrigeration circuit

Detection and understanding of the cyclic process

Changes of state of the refrigerant

Representation the refrigeration circuit in the process

schematic

Representation of the cyclic process in the log p-h diagram

Estimating key figures, refrigeration capacity and heat

fluxes

Different operating modes

Air cooling

Generating cold water

Heat pump (generate hot water)

Practical exercises

Draining and filling the refrigeration system

Fault finding

Specification

Setup of simple refrigeration circuits with different

components

8 self-contained operational modules mounted on a plate each

Light-weight aluminium frame to arrange 6 modules

Evaporator and condenser each available as air/refrigerant

heat exchanger (finned tube heat exchanger) and as water/refrigerant heat

exchanger (with pipe coil)

Modules fitted with manual valves

Components connected via hoses

Technical Data

Hermetic refrigerant compressor

power consumption: 67W at 5/40°C

refrigeration capacity: 152W at 5/40°C

Tank content

water tank, evaporator: 2L

water tank, condenser: 3L

Pressure switch activation pressure

LP: 1bar

HP: 14bar

Manometer

inlet side (low pressure): 1…10bar

outlet side (high pressure): 1…30bar

Rotameter: 0…7,4L/h

Refrigerant

R513A

GWP: 631

filling volume: 400g

CO2-equivalent: 0,3t

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.