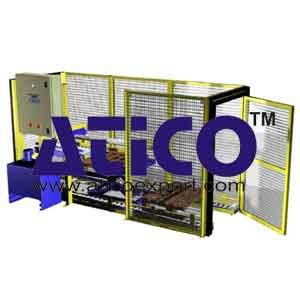

Pallet Storage System

Categories:It permits to pallet the fertilizer bag according to two types of configurations: Chimney Configuration Epi Configuration : The industrial PLC wich manages the process must take in account different i...

Product

Description

It permits to pallet the fertilizer bag according to two types of configurations:

Chimney Configuration Epi Configuration :

The industrial PLC wich manages the process must take in account different informations relative to physical states as:- The presence of a bag to the input of the system.

- The switch position.

- The presence of bags at the exit.

- The rank of the bag during the palleting process.

Composition of the equipment:

The system includes a switching functional chain of the bags ref a configuration and orientation functional subset of the bags ref and a module.

These three elements permit a progressive approach of the palleting process technology, and practical works oriented toward the knowledge of the sensors, pre actuators, actuators, effectors, the mechanical links and the initiation to automatics.

Training documents supplied:

- A technical file including: The documentation of the components, the electric and pneumatics diagrams, the PLC program.

- A student file including the practical works.

Operative part

- Transfer by non end conveyor belt.

- Switching of bags by gearwheel-rack.

- Orientation of bags by air jacks.

- Configuration of the pallets by air jacks.

- Evacuation of the layer constituted by air jacks.

Pre actuators

- Contactors.

- Bistable distributors 5/2.

- Monostable distributors 5/2.

- Electro pneumatic Interfaces 3/2.

Actuators

- 2 reduction gears.

- 5 air jacks, double effect.

Sensors

- Photoelectric detectors.

- Inductive detectors.

- ILS detectors on jacks.

- Control part

- PLC SCHNEIDER.

- Control desk.

Dimensions

- L x w x h = 1000 x 600 x 510mm.

- Mass: 68 kg.

- Necessary energy.

- Electricity: 220 V AC mono phase.

- Air compressed 6 bar.

Training features

- The system permits to visualize 5 operative tasks analyzed under a S.A.D.T form.

- The cycle is described by GRAFCET and GEMMA.

- The practical works permit to understand the various sequences of the program.

Teaching objectives

Mechanical engineering- Transformation of the circular movement in rectilinear motion (motor-reduction gear-pulleys and belts). Automatics.

- The system permits the simulation of the GRAFCET and the exploitation of the GEMMA for the complete system.

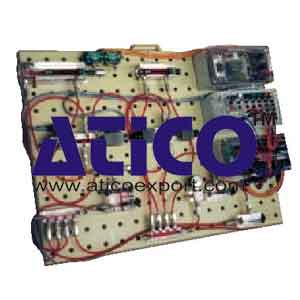

- Switching functional chain of the bag (Functions with the module).

Teaching objectives

- Transformation of the circular movement in rectilinear motion (motor-reduction gear- gearwheel-rack),

- Measure of force, distance, time, displacement, electrical tension and current,

- Energy balance, notion of efficiency.

Automatics

- Connection of the pre actuator to the motor.

- Connection of the pre actuator to the PO.

- Simulation of the GRAFCET cycle.

- Dimensions: L x w x h = 500 x 360 x 230mm.

- Mass: 8 kg.

- Configuration and orientation functional subsystem of the (Functions with the module).

Teaching objectives

- Study of links: pivot, ball an socket joint, linear straight.

- Transformation of the straight linear movement in circular movement.

Automatics

- Connection of the air actuator.

- Connection of the pneumatic pre actuator to its control devise (switch button).

- Connection of the pneumatic pre actuator to the electro pneumatic interfaces.

- Connection of the electro pneumatic interfaces to the PLC.

- Simulation of the cycle relative to the studied module.

- Dimensions: L x w x h = 500 x 360 x 230mm.

quick overview :

It permits to pallet the fertilizer bag according to two types of configurations:

Chimney Configuration Epi Configuration :

The industrial PLC wich manages the process must take in account different informations relative to physical states as:- The presence of a bag to the input of the system.

- The switch position.

- The presence of bags at the exit.

- The rank of the bag during the palleting process.

Composition of the equipment:

The system includes a switching functional chain of the bags ref a configuration and orientation functional subset of the bags ref and a module.

These three elements permit a progressive approach of the palleting process technology, and practical works oriented toward the knowledge of the sensors, pre actuators, actuators, effectors, the mechanical links and the initiation to automatics.

Training documents supplied:

- A technical file including: The documentation of the components, the electric and pneumatics diagrams, the PLC program.

- A student file including the practical works.

Operative part

- Transfer by non end conveyor belt.

- Switching of bags by gearwheel-rack.

- Orientation of bags by air jacks.

- Configuration of the pallets by air jacks.

- Evacuation of the layer constituted by air jacks.

Pre actuators

- Contactors.

- Bistable distributors 5/2.

- Monostable distributors 5/2.

- Electro pneumatic Interfaces 3/2.

Actuators

- 2 reduction gears.

- 5 air jacks, double effect.

Sensors

- Photoelectric detectors.

- Inductive detectors.

- ILS detectors on jacks.

- Control part

- PLC SCHNEIDER.

- Control desk.

Dimensions

- L x w x h = 1000 x 600 x 510mm.

- Mass: 68 kg.

- Necessary energy.

- Electricity: 220 V AC mono phase.

- Air compressed 6 bar.

Training features

- The system permits to visualize 5 operative tasks analyzed under a S.A.D.T form.

- The cycle is described by GRAFCET and GEMMA.

- The practical works permit to understand the various sequences of the program.

Teaching objectives

Mechanical engineering- Transformation of the circular movement in rectilinear motion (motor-reduction gear-pulleys and belts). Automatics.

- The system permits the simulation of the GRAFCET and the exploitation of the GEMMA for the complete system.

- Switching functional chain of the bag (Functions with the module).

Teaching objectives

- Transformation of the circular movement in rectilinear motion (motor-reduction gear- gearwheel-rack),

- Measure of force, distance, time, displacement, electrical tension and current,

- Energy balance, notion of efficiency.

Automatics

- Connection of the pre actuator to the motor.

- Connection of the pre actuator to the PO.

- Simulation of the GRAFCET cycle.

- Dimensions: L x w x h = 500 x 360 x 230mm.

- Mass: 8 kg.

- Configuration and orientation functional subsystem of the (Functions with the module).

Teaching objectives

- Study of links: pivot, ball an socket joint, linear straight.

- Transformation of the straight linear movement in circular movement.

Automatics

- Connection of the air actuator.

- Connection of the pneumatic pre actuator to its control devise (switch button).

- Connection of the pneumatic pre actuator to the electro pneumatic interfaces.

- Connection of the electro pneumatic interfaces to the PLC.

- Simulation of the cycle relative to the studied module.

- Dimensions: L x w x h = 500 x 360 x 230mm.

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.