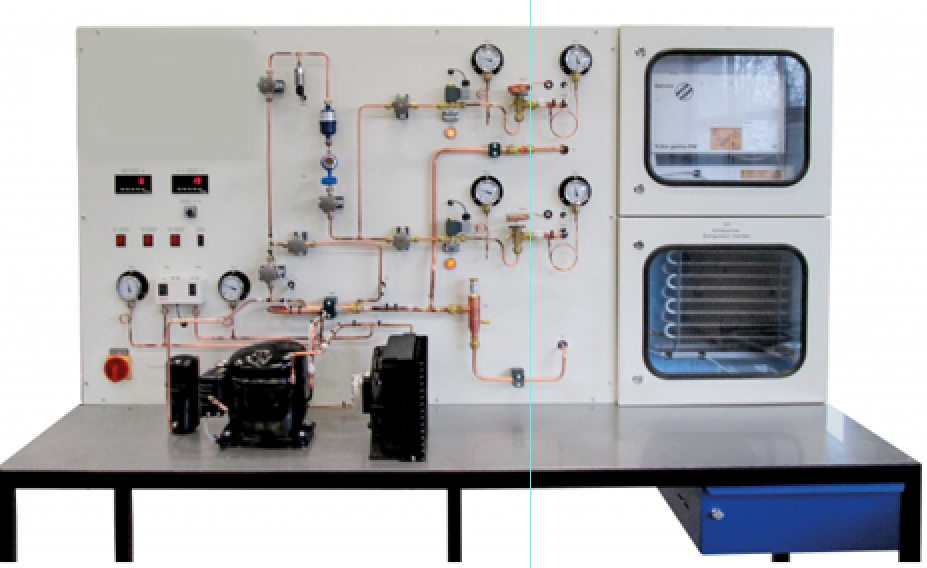

Refrigeration System With Refrigeration And Freezing Chamber

Categories: Engineering Lab EquipmentIdentifying faults in refrigeration systems requires comprehensive knowledge This includes knowledge of the structure and the task of the individual components. With this, the design and components of...

Product

Description

Identifying faults in refrigeration systems requires

comprehensive knowledge This includes knowledge of the structure and the task

of the individual components. With this, the design and components of a

refrigeration system can be examined. The simulation of typical errors extends

the scope of the experiment. The components of a refrigeration circuit with

refrigeration and freezing chambers are arranged clearly in the trainer.

Solenoid valves enable the individual or parallel operation of the evaporators

in the two chambers. The circuit is equipped with a combined pressure switch

for the delivery and intake side of the compressor. The refrigeration chamber

features an evaporation pressure controller. The effect of the evaporation

pressure controller on the overall process is being examined. An inner heat

exchanger in the inlet of the two evaporators is used for supercooling the

refrigerant to increase the efficiency of the process. At the same time the

intake gas is superheated.

Learning Objectives/Experiments

Design and components of a refrigeration system with 2

evaporators

Components and their functions

Compressor, condenser, evaporator

Thermostatic expansion valve

Evaporation pressure controller

Pressure switch

Electric defrost heater

Thermodynamics of the refrigeration cycle

Effect of refrigerant supercooling

Representation of the thermodynamic cycle in the log p-h

diagram

Determination of important characteristic variables:

coefficient of performance, refrigeration capacity, compressor work

Fault finding in refrigeration system components

Specification

Investigation of a refrigeration system with refrigeration

and freezing chambers

Refrigeration circuit with compressor, condenser and 2

evaporators with thermostatic expansion valve and evaporation pressure

controller

Insulated freezing chamber with fan and electric defrost

heater

Insulated refrigeration chamber with evaporation pressure

controller

Heat exchanger for refrigerant supercooling

Individual or parallel operation of the chambers via

solenoid valves

Sensors record pressure and temperature

Refrigerant mass flow rate calculated in the software from

recorded measured values

Simulation of 18 faults

Technical Data

Compressor

power consumption: 565W at 7,2/54,4°C

refrigeration capacity: 1363W at 7,2/54,4°C

Condenser with fan

volumetric air flow rate: 290m3/h

transfer area: 1,5m2

Refrigeration chamber

evaporator transfer area: 1,06m2

Freezing chamber

evaporator transfer area: 2,42m2

volumetric air flow rate, fan: 135m3/h

electric defrost heater: approx. 150W

Evaporation pressure controller: 0…5,5bar

Refrigerant: R513A, GWP: 631

filling volume: 1,5kg

CO2-equivalent: 0,9t

Measuring ranges

temperature: 12x -50…120°C

pressure: 3x -1…15bar, 3x -1…9bar, 3x -1…24bar

power: 0…1125W

flow rate: 1…11,5L/h

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

quick overview :

Identifying faults in refrigeration systems requires

comprehensive knowledge This includes knowledge of the structure and the task

of the individual components. With this, the design and components of a

refrigeration system can be examined. The simulation of typical errors extends

the scope of the experiment. The components of a refrigeration circuit with

refrigeration and freezing chambers are arranged clearly in the trainer.

Solenoid valves enable the individual or parallel operation of the evaporators

in the two chambers. The circuit is equipped with a combined pressure switch

for the delivery and intake side of the compressor. The refrigeration chamber

features an evaporation pressure controller. The effect of the evaporation

pressure controller on the overall process is being examined. An inner heat

exchanger in the inlet of the two evaporators is used for supercooling the

refrigerant to increase the efficiency of the process. At the same time the

intake gas is superheated.

Learning Objectives/Experiments

Design and components of a refrigeration system with 2

evaporators

Components and their functions

Compressor, condenser, evaporator

Thermostatic expansion valve

Evaporation pressure controller

Pressure switch

Electric defrost heater

Thermodynamics of the refrigeration cycle

Effect of refrigerant supercooling

Representation of the thermodynamic cycle in the log p-h

diagram

Determination of important characteristic variables:

coefficient of performance, refrigeration capacity, compressor work

Fault finding in refrigeration system components

Specification

Investigation of a refrigeration system with refrigeration

and freezing chambers

Refrigeration circuit with compressor, condenser and 2

evaporators with thermostatic expansion valve and evaporation pressure

controller

Insulated freezing chamber with fan and electric defrost

heater

Insulated refrigeration chamber with evaporation pressure

controller

Heat exchanger for refrigerant supercooling

Individual or parallel operation of the chambers via

solenoid valves

Sensors record pressure and temperature

Refrigerant mass flow rate calculated in the software from

recorded measured values

Simulation of 18 faults

Technical Data

Compressor

power consumption: 565W at 7,2/54,4°C

refrigeration capacity: 1363W at 7,2/54,4°C

Condenser with fan

volumetric air flow rate: 290m3/h

transfer area: 1,5m2

Refrigeration chamber

evaporator transfer area: 1,06m2

Freezing chamber

evaporator transfer area: 2,42m2

volumetric air flow rate, fan: 135m3/h

electric defrost heater: approx. 150W

Evaporation pressure controller: 0…5,5bar

Refrigerant: R513A, GWP: 631

filling volume: 1,5kg

CO2-equivalent: 0,9t

Measuring ranges

temperature: 12x -50…120°C

pressure: 3x -1…15bar, 3x -1…9bar, 3x -1…24bar

power: 0…1125W

flow rate: 1…11,5L/h

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.