Refrigerator Model

Categories: Engineering Lab EquipmentIt is part of the HSI training system for refrigeration and air conditioning technology. In combination with the base unit the operational model of a domestic refrigerator is created. The model is plu...

Product

Description

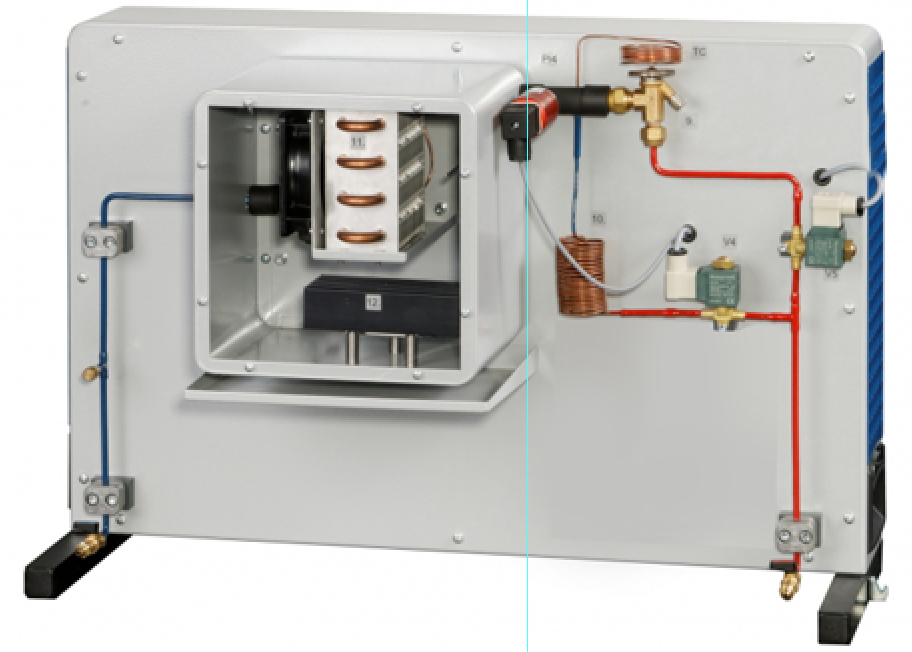

It is part of the HSI training system for refrigeration and

air conditioning technology. In combination with the base unit the operational

model of a domestic refrigerator is created. The model is plugged onto the base

unit, secured using fasteners and connected with refrigerant hoses to become a

complete refrigeration circuit. It consists of a refrigeration chamber with a

heater as cooling load, evaporator, fan and various expansion elements. The fan

supports the achievement of an even temperature distribution in the chamber. A

cooling load can additionally be simulated with the heater. Solenoid valves

enable the operation of the system with capillary tube or with expansion valve.

All components are clearly arranged on a panel. The operation of individual

system components, here the temperature control, fan, heater, compressor and

solenoid valves, takes place via the software. The software offers the option

to simulate faults.

Learning Objectives/Experiments

Design and operation of a simple refrigeration system

Different expansion elements

Operation with capillary tube

Operation with expansion valve

Operating behaviour under load

Refrigeration cycle in the log p-h diagram

Fault simulation

Features

Simple model of a domestic refrigerator for connection to

the HSI Training System Refrigeration And Air Conditioning Unit

Component operation and fault simulation via the software

Specification

Model of a refrigerator to plug onto the base unit

Training system with HSI technology

Refrigeration chamber with evaporator, fan and cooling load

Chamber with transparent front

Electric heater to generate the cooling load

Expansion elements selectable via solenoid valves: expansion

valve or capillary tube

Sensors to record temperature and pressure

Operation of solenoid valves, fan, heater and fault

simulation via software

Software: educational software, data acquisition, system

operation

Technical Data

Refrigeration chamber, LxWxH: 270x270x220mm

Electric PTC heater as cooling load: 210W

Capillary tube: length 2m

Measuring ranges

temperature: 3x -50…50°C

pressure: -1…9bar

quick overview :

It is part of the HSI training system for refrigeration and

air conditioning technology. In combination with the base unit the operational

model of a domestic refrigerator is created. The model is plugged onto the base

unit, secured using fasteners and connected with refrigerant hoses to become a

complete refrigeration circuit. It consists of a refrigeration chamber with a

heater as cooling load, evaporator, fan and various expansion elements. The fan

supports the achievement of an even temperature distribution in the chamber. A

cooling load can additionally be simulated with the heater. Solenoid valves

enable the operation of the system with capillary tube or with expansion valve.

All components are clearly arranged on a panel. The operation of individual

system components, here the temperature control, fan, heater, compressor and

solenoid valves, takes place via the software. The software offers the option

to simulate faults.

Learning Objectives/Experiments

Design and operation of a simple refrigeration system

Different expansion elements

Operation with capillary tube

Operation with expansion valve

Operating behaviour under load

Refrigeration cycle in the log p-h diagram

Fault simulation

Features

Simple model of a domestic refrigerator for connection to

the HSI Training System Refrigeration And Air Conditioning Unit

Component operation and fault simulation via the software

Specification

Model of a refrigerator to plug onto the base unit

Training system with HSI technology

Refrigeration chamber with evaporator, fan and cooling load

Chamber with transparent front

Electric heater to generate the cooling load

Expansion elements selectable via solenoid valves: expansion

valve or capillary tube

Sensors to record temperature and pressure

Operation of solenoid valves, fan, heater and fault

simulation via software

Software: educational software, data acquisition, system

operation

Technical Data

Refrigeration chamber, LxWxH: 270x270x220mm

Electric PTC heater as cooling load: 210W

Capillary tube: length 2m

Measuring ranges

temperature: 3x -50…50°C

pressure: -1…9bar

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.