Separation In Sedimentation Tanks

Categories: Engineering Lab EquipmentIn sedimentation tanks, solids are separated out from suspensions under the influence of gravity. In this process the density of the solid particles must be greater than that of the liquid. It makes i...

Product

Description

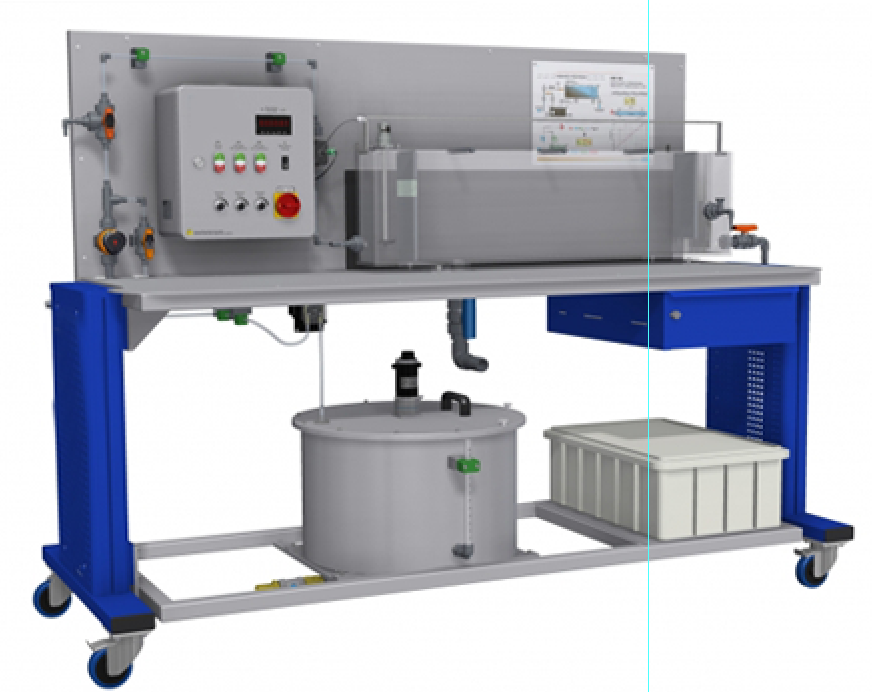

In sedimentation tanks, solids are separated out from suspensions under the influence of gravity. In this process the density of the solid particles must be greater than that of the liquid. It makes it possible to investigate the separation of solids from a suspension in a sedimentation tank.

First a concentrated suspension is prepared in a tank, comprising water and the solid to be separated. A pump transports the concentrated suspension to the sedimentation tank. Upstream of the sedimentation tank the suspension is mixed with fresh water. The raw water generated in this way flows into the sedimentation tank via an inlet weir. A stirring machine is located upstream of the inlet weir. This prevents solids sedimenting before entering the sedimentation tank. The treated water first flows under a baffle and then over a weir to the outlet.

Learning Objectives/Experiments

Bed-load transport in open channels

Subcritical and supercritical flow

Formation of ripples, dunes and antidunes

How flow velocity affects bed-load transport

Fluvial obstacle mark (siltation/scour formation)

Bridge pier

Sluice gate

Visualisation of the flow

Open-channel flow without sediment transport

Subcritical and supercritical flow

Control structure: sluice gate

Discharge measurement on the sharp-crested weir

Specification

Separation of suspensions by sedimentation in the sedimentation tank

Transparent sedimentation tank with lighting for visualisation of the flow conditions

Stirring machine in the inlet area of the sedimentation tank

Lamella unit can optionally be inserted into the sedimentation tank

Tank with pump and stirring machine to create and transport a concentrated suspension

Mixture of the concentrated suspension with fresh water gives the raw water to be studied

Adjustment of the concentration of solids via valves for fresh water flow rate and suspension flow rate

Adjustable water level in the sedimentation tank and adjustable flow velocity in the inlet

Electromagnetic flow rate sensor for raw water

Lmhoff cones for determining settleable substances of a water sample

Technical data

Sedimentation tank (experimental section)

LxWxH: 900x110x300mm

max. filling capacity: approx. 25L

material: plexiglass

Lamella unit

angle of inclination of lamellas: 60°

number of lamellas: 16

Suspension tank

capacity: approx. 85L

material: stainless steel

Pump

max. flow rate: 75L/h

Stirring machines (max. speed)

suspension tank: 600min-1

sedimentation tank: 330min-1

Measuring ranges

flow rate: 30…600L/h

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

quick overview :

In sedimentation tanks, solids are separated out from suspensions under the influence of gravity. In this process the density of the solid particles must be greater than that of the liquid. It makes it possible to investigate the separation of solids from a suspension in a sedimentation tank.

First a concentrated suspension is prepared in a tank, comprising water and the solid to be separated. A pump transports the concentrated suspension to the sedimentation tank. Upstream of the sedimentation tank the suspension is mixed with fresh water. The raw water generated in this way flows into the sedimentation tank via an inlet weir. A stirring machine is located upstream of the inlet weir. This prevents solids sedimenting before entering the sedimentation tank. The treated water first flows under a baffle and then over a weir to the outlet.

Learning Objectives/Experiments

Bed-load transport in open channels

Subcritical and supercritical flow

Formation of ripples, dunes and antidunes

How flow velocity affects bed-load transport

Fluvial obstacle mark (siltation/scour formation)

Bridge pier

Sluice gate

Visualisation of the flow

Open-channel flow without sediment transport

Subcritical and supercritical flow

Control structure: sluice gate

Discharge measurement on the sharp-crested weir

Specification

Separation of suspensions by sedimentation in the sedimentation tank

Transparent sedimentation tank with lighting for visualisation of the flow conditions

Stirring machine in the inlet area of the sedimentation tank

Lamella unit can optionally be inserted into the sedimentation tank

Tank with pump and stirring machine to create and transport a concentrated suspension

Mixture of the concentrated suspension with fresh water gives the raw water to be studied

Adjustment of the concentration of solids via valves for fresh water flow rate and suspension flow rate

Adjustable water level in the sedimentation tank and adjustable flow velocity in the inlet

Electromagnetic flow rate sensor for raw water

Lmhoff cones for determining settleable substances of a water sample

Technical data

Sedimentation tank (experimental section)

LxWxH: 900x110x300mm

max. filling capacity: approx. 25L

material: plexiglass

Lamella unit

angle of inclination of lamellas: 60°

number of lamellas: 16

Suspension tank

capacity: approx. 85L

material: stainless steel

Pump

max. flow rate: 75L/h

Stirring machines (max. speed)

suspension tank: 600min-1

sedimentation tank: 330min-1

Measuring ranges

flow rate: 30…600L/h

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.