Shell and Tube Exchanger

Categories: Heating Cooling Trainer[subtitle2]Shell and Tube Exchanger[/subtitle2] Our enterprise holds the specialization in the manufacturing, trading and exporting of optimum quality Shell & Tube Type Heat Exchanger. M...

Product

Description

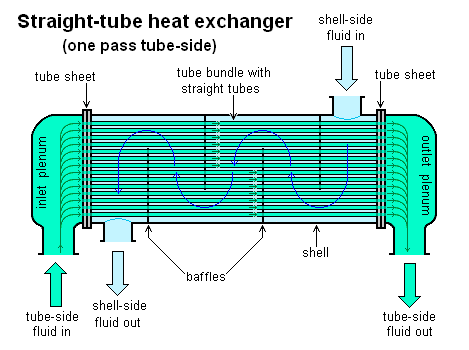

[subtitle2]Shell and Tube Exchanger[/subtitle2] Our enterprise holds the specialization in the manufacturing, trading and exporting of optimum quality Shell & Tube Type Heat Exchanger. Manufactured under strict supervision, these heat exchangers are provided with rigid MS Structure. To manufacture best quality heat exchangers, our professionals use best quality metal and latest technologies. Offered heat exchangers are easy to install and appreciated for hassle-free performance. Description:

- Shell and Tube Heat Exchanger are popular in process industries because they occupy less space and offer reasonable temperature drop. The apparatus consists of fabricated shell, inside which tubes with baffles on outer side are fitted. The present set up is a 1-2 heat exchangers, with cold water flows through shell. Valves are provided to control the flow rates of hot and cold water. Flow rates of hot and cold water are measured using Rotameters. A magnetic drive pump is used to circulate the hot water from a re-cycled type water tank, which is fitted with heaters and Digital Temperature Controller.

- LMTD

- Heat transfer rate

- Overall Heat Transfer Co-efficient

- Water supply 20 lit/min (approx.) and drain.

- Electricity Supply : 1 Phase, 220 V AC, 4 kW.

- Floor area of 1.5 m x 0.75 m.

- System: Water to Water. (1–2 shell & tube type)

- Shell: Material Stainless steel. Insulated with ceramic wool and cladded with aluminum foil. Dia. 220 mm, Length 500 mm (Approx.)

- 25% cut baffles at 100 mm distance 4 Nos

- Tube: OD 16mm approx., Length 500mm (24 Nos.)

- Water Flow Measurement: Rotameters (2Nos.) one each for cold & hot fluid

- Hot Water Tank: Made of Stainless steel Insulated with ceramic fibre wool

- Hot Water Circulation: Magnetic Pump

- Heaters: Nichrome wire heater (2 Nos.)

- Digital Temp. Controller: 0-199.90C, (For Hot Water Tank)

- Digital Temp. Indicator: 0-199.90C, with multi-channel switch

- Temperature sensors: RTD PT-100 type

- Instruction Manual: An english instruction manual will be provided along with the Apparatus

- A good quality painted rigid MS Structure is provided to support all the parts

quick overview :

[subtitle2]Shell and Tube Exchanger[/subtitle2] Our enterprise holds the specialization in the manufacturing, trading and exporting of optimum quality Shell & Tube Type Heat Exchanger. Manufactured under strict supervision, these heat exchangers are provided with rigid MS Structure. To manufacture best quality heat exchangers, our professionals use best quality metal and latest technologies. Offered heat exchangers are easy to install and appreciated for hassle-free performance. Description:

- Shell and Tube Heat Exchanger are popular in process industries because they occupy less space and offer reasonable temperature drop. The apparatus consists of fabricated shell, inside which tubes with baffles on outer side are fitted. The present set up is a 1-2 heat exchangers, with cold water flows through shell. Valves are provided to control the flow rates of hot and cold water. Flow rates of hot and cold water are measured using Rotameters. A magnetic drive pump is used to circulate the hot water from a re-cycled type water tank, which is fitted with heaters and Digital Temperature Controller.

- LMTD

- Heat transfer rate

- Overall Heat Transfer Co-efficient

- Water supply 20 lit/min (approx.) and drain.

- Electricity Supply : 1 Phase, 220 V AC, 4 kW.

- Floor area of 1.5 m x 0.75 m.

- System: Water to Water. (1–2 shell & tube type)

- Shell: Material Stainless steel. Insulated with ceramic wool and cladded with aluminum foil. Dia. 220 mm, Length 500 mm (Approx.)

- 25% cut baffles at 100 mm distance 4 Nos

- Tube: OD 16mm approx., Length 500mm (24 Nos.)

- Water Flow Measurement: Rotameters (2Nos.) one each for cold & hot fluid

- Hot Water Tank: Made of Stainless steel Insulated with ceramic fibre wool

- Hot Water Circulation: Magnetic Pump

- Heaters: Nichrome wire heater (2 Nos.)

- Digital Temp. Controller: 0-199.90C, (For Hot Water Tank)

- Digital Temp. Indicator: 0-199.90C, with multi-channel switch

- Temperature sensors: RTD PT-100 type

- Instruction Manual: An english instruction manual will be provided along with the Apparatus

- A good quality painted rigid MS Structure is provided to support all the parts

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

.jpg)

Product

Reviews

add Review

reviews

No Review Yet.