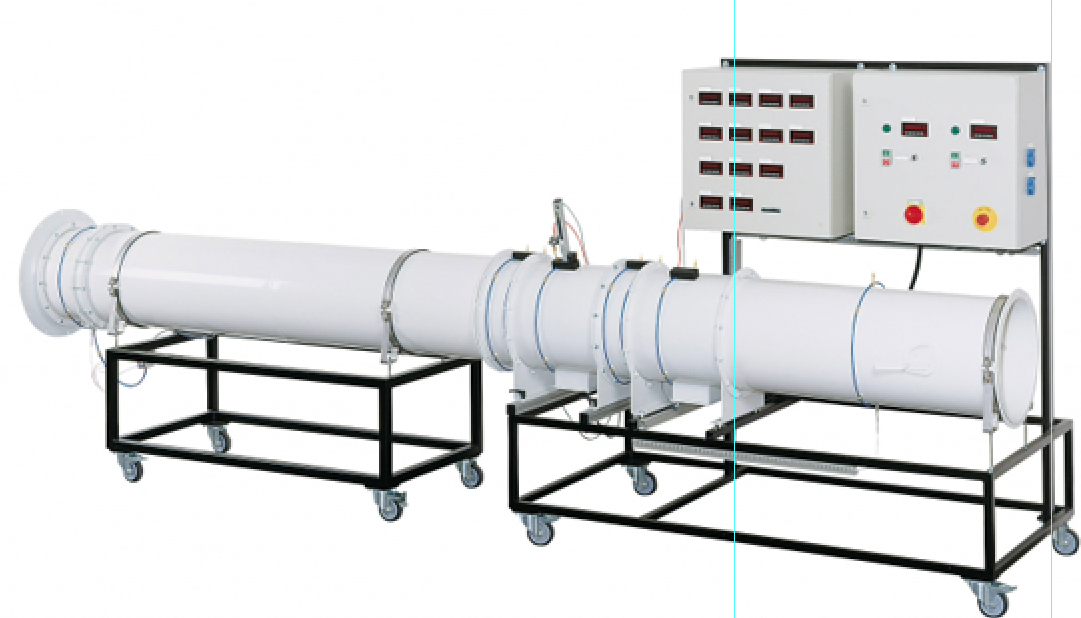

Two Stage Axial Fan

Categories: Engineering Lab EquipmentAxial fans are connected in series in plants to increase the pressure. In theory, connecting two fans in series doubles the pressure increase.The trainer allows the investigation of a two-stage axial...

Product

Description

Axial fans are connected in series in plants to increase the pressure. In theory, connecting two fans in series doubles the pressure increase.

The trainer allows the investigation of a two-stage axial fan. A measuring device is used to determine the pressure and velocity distribution.

The trainer includes a measuring section with two identical axial fans. The carefully designed nozzle contour and a flow straightener at the air inlet ensure a uniform velocity distribution with little turbulence in the measuring section. The rotors are equipped with individually adjustable blades to change the angle of attack. The fans are equipped with outlet guide vane systems. These guide mechanisms redirect the angular momentum of the outflow in the axial direction and allow an increase in pressure. A pipe bend may optionally be installed to rotate the flow at the outlet of the measuring section. One of the fans can be removed from the measuring section so that the remaining fan can be studied in individual operation.

Learning Objectives/Experiments

Determining the fan characteristic

Series configuration or individual operation of axial fans

Determining the energy balance

Determining the radial pressure and velocity distribution on rotor and guide vane system by means of a probe

Effect of the blade position

Features

Two axial fans in series configuration or in individual operation

Three-hole probe for determining pressure and velocity profile

Specification

Investigate two-stage axial fan

2 identical single-stage fans in series configuration or individual operation

Individually adjustable blades

Fans both with variable speed via frequency converter

Flow-optimised nozzle and flow straightener for smooth, low-turbulence flow

Air flow in the pipe section can be adjusted via throttle valve

Optional pipe bend at the outlet for flow deflection

Measuring device with three-hole probe for determining the differential pressure on rotor and guide vane system

Sensors for pressure and temperature upstream and downstream of each fan

Volumetric flow rate measured via inlet nozzle

Technical data

2 fans

drive motor rated output: 3,45kW

max. pressure difference: 798Pa

speed: 0…2850min-1

blade angle adjustable up to 39°

Measuring section inner diameter: 400mm

Measuring ranges

temperature: 0…100°C

differential pressure: ±25mbar

radial position of the probe: 100…200mm

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases

quick overview :

Axial fans are connected in series in plants to increase the pressure. In theory, connecting two fans in series doubles the pressure increase.

The trainer allows the investigation of a two-stage axial fan. A measuring device is used to determine the pressure and velocity distribution.

The trainer includes a measuring section with two identical axial fans. The carefully designed nozzle contour and a flow straightener at the air inlet ensure a uniform velocity distribution with little turbulence in the measuring section. The rotors are equipped with individually adjustable blades to change the angle of attack. The fans are equipped with outlet guide vane systems. These guide mechanisms redirect the angular momentum of the outflow in the axial direction and allow an increase in pressure. A pipe bend may optionally be installed to rotate the flow at the outlet of the measuring section. One of the fans can be removed from the measuring section so that the remaining fan can be studied in individual operation.

Learning Objectives/Experiments

Determining the fan characteristic

Series configuration or individual operation of axial fans

Determining the energy balance

Determining the radial pressure and velocity distribution on rotor and guide vane system by means of a probe

Effect of the blade position

Features

Two axial fans in series configuration or in individual operation

Three-hole probe for determining pressure and velocity profile

Specification

Investigate two-stage axial fan

2 identical single-stage fans in series configuration or individual operation

Individually adjustable blades

Fans both with variable speed via frequency converter

Flow-optimised nozzle and flow straightener for smooth, low-turbulence flow

Air flow in the pipe section can be adjusted via throttle valve

Optional pipe bend at the outlet for flow deflection

Measuring device with three-hole probe for determining the differential pressure on rotor and guide vane system

Sensors for pressure and temperature upstream and downstream of each fan

Volumetric flow rate measured via inlet nozzle

Technical data

2 fans

drive motor rated output: 3,45kW

max. pressure difference: 798Pa

speed: 0…2850min-1

blade angle adjustable up to 39°

Measuring section inner diameter: 400mm

Measuring ranges

temperature: 0…100°C

differential pressure: ±25mbar

radial position of the probe: 100…200mm

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.