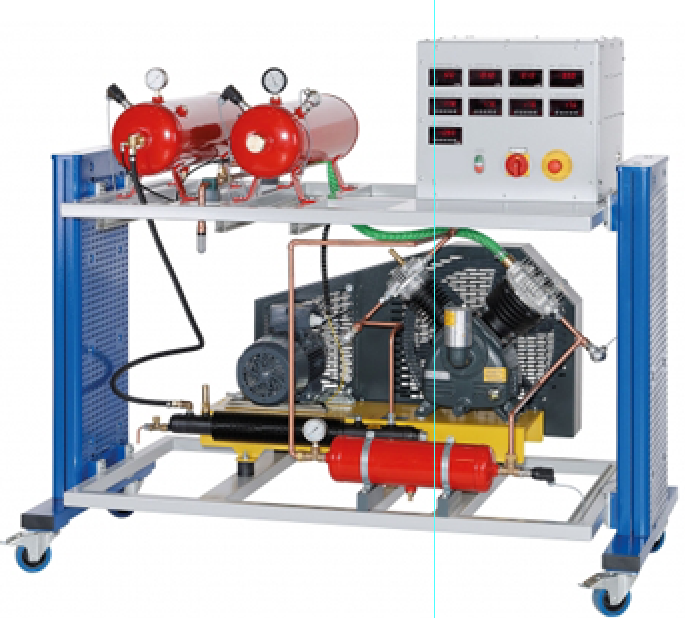

Two Stage Piston Compressor

Categories: Engineering Lab EquipmentCompressed air for industry and businesses that use compressed air as an energy source is generated by means of so-called compressed air generation systems. A key component of these systems is the com...

Product

Description

Compressed air for industry and businesses that use compressed air as an energy source is generated by means of so-called compressed air generation systems. A key component of these systems is the compressor. It converts the supplied mechanical energy into a higher air pressure. Compressed air generation systems are used to drive machines in mining, for pneumatic control systems in assembly plants or tyre inflation systems at petrol stations.

It includes a complete compressed air generation system with a two-stage compressor and an additional pressure vessel as intercooler. The trainer enables the recording of compressor characteristics and representing the compression process in a p-V diagram.

Learning Objectives/Experiments

Design and function of a two-stage compressor

Measurement of relevant pressures and temperatures

Determination of the intake volumetric air flow rate

Compression process on a p-V diagram

Determination of the efficiency

Features

Two-stage compressor with intercooler

Compression process on a p-V diagram

Specification

Recording the characteristic of a two-stage compressor

Piston compressor with 2 cylinders in V-arrangement

Intake vessel with nozzle to measure the intake volumetric flow rate, pressure sensor and additional manometer

Pressure vessel after the first stage as intercooler

Pressure vessel after the second stage with safety valve, blow-off valve and silencer as well as an additional manometer and a pressure switch

Sensors for pressures, temperatures and electric power output

Digital displays for temperatures, pressures, differential pressures and electric power output

Technical Data

Compressor

two-stage

with 2 cylinders in a V-arrangement

power consumption: 3kW

speed: 710min-1

intake capacity: 250L/min

quantity delivered: 202L/min (at 12bar)

operating pressure: 12bar, max. 35bar

Intake vessel: 20L

Pressure vessels, 16bar; capacity:

after 1st stage: 5L

after 2nd stage: 20L

Safety valve: 16bar

Measuring ranges

differential pressure: 0…25mbar

pressure: 1x 0…1,5bar; 2x 0…16bar

temperature: 4x 0…200°C

power: 0…3500W

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases

230V, 60Hz, 3 phases

quick overview :

Compressed air for industry and businesses that use compressed air as an energy source is generated by means of so-called compressed air generation systems. A key component of these systems is the compressor. It converts the supplied mechanical energy into a higher air pressure. Compressed air generation systems are used to drive machines in mining, for pneumatic control systems in assembly plants or tyre inflation systems at petrol stations.

It includes a complete compressed air generation system with a two-stage compressor and an additional pressure vessel as intercooler. The trainer enables the recording of compressor characteristics and representing the compression process in a p-V diagram.

Learning Objectives/Experiments

Design and function of a two-stage compressor

Measurement of relevant pressures and temperatures

Determination of the intake volumetric air flow rate

Compression process on a p-V diagram

Determination of the efficiency

Features

Two-stage compressor with intercooler

Compression process on a p-V diagram

Specification

Recording the characteristic of a two-stage compressor

Piston compressor with 2 cylinders in V-arrangement

Intake vessel with nozzle to measure the intake volumetric flow rate, pressure sensor and additional manometer

Pressure vessel after the first stage as intercooler

Pressure vessel after the second stage with safety valve, blow-off valve and silencer as well as an additional manometer and a pressure switch

Sensors for pressures, temperatures and electric power output

Digital displays for temperatures, pressures, differential pressures and electric power output

Technical Data

Compressor

two-stage

with 2 cylinders in a V-arrangement

power consumption: 3kW

speed: 710min-1

intake capacity: 250L/min

quantity delivered: 202L/min (at 12bar)

operating pressure: 12bar, max. 35bar

Intake vessel: 20L

Pressure vessels, 16bar; capacity:

after 1st stage: 5L

after 2nd stage: 20L

Safety valve: 16bar

Measuring ranges

differential pressure: 0…25mbar

pressure: 1x 0…1,5bar; 2x 0…16bar

temperature: 4x 0…200°C

power: 0…3500W

400V, 50Hz, 3 phases

400V, 60Hz, 3 phases

230V, 60Hz, 3 phases

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.