Vertical Flow From A Tank

Categories: Engineering Lab EquipmentPressure losses in the flow from tanks are essentially the result of two processes: the jet deflection upon entry into the opening and the wall friction in the opening. As a result of the pressure los...

Product

Description

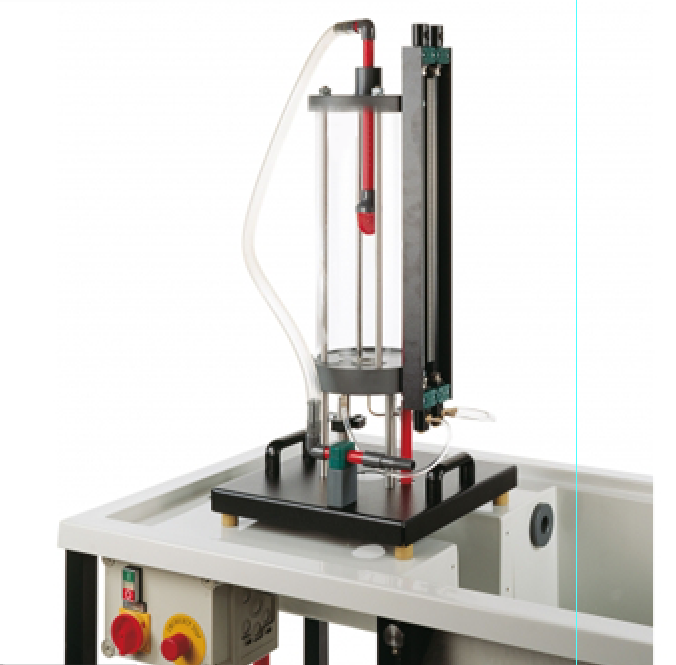

Pressure losses in the flow from tanks are essentially the result of two processes: the jet deflection upon entry into the opening and the wall friction in the opening. As a result of the pressure losses the real discharge is smaller than the theoretical flow rate.

It determines these losses at different flow rates. Different diameters as well as inlet and outlet contours of the openings can be studied. Additionally, the contraction coefficient can be determined as a characteristic for different contours.

The experimental unit includes a transparent tank, a measuring device as well as a Pitot tube and twin tube manometers. An interchangeable insert is installed in the tank’s water outlet to facilitate the investigation of various openings. Five inserts with different diameters, inlet contours and outlet contours are provided along with the unit.

The issued water jet is measured using a measuring device. A Pitot tube detects the total pressure of the flow. The pressure difference (read on the manometer) is used to determine the velocity.

Learning Objectives/Experiments

Study of the outlet jet (diameter, velocity)

Determination of pressure losses and contraction coefficient for different outlet contours

Determination of flow rate at different discharge heads

Features

Determination of the diameter and velocity of the outlet jet

Study of openings with different inlet and outlet contours

Determining the contraction coefficient

Specification

Study of pressure losses in vertical flows from tanks

Determining the contraction coefficient for different contours and diameters

Tank with adjustable overflow

5 interchangeable inserts with different contours

Measuring device for determining the jet diameter

Pitot tube for determining the total pressure

Pressure display on twin tube manometers

Flow rate determined by base module

Water supply using base module or via laboratory supply

Technical data

Tank

capacity: approx. 13L

overflow height: max. 400mm

max. flow rate: 14L/min

Inserts

Inner diameters: d1=inlet, d2=outlet

1x cylindrical hole, d=12mm

1x outlet from the insert: cone d1=24mm, d2=12mm

1x inlet to the insert: orifice plate d1=24mm, d2=12mm

1x inlet to the insert: cone d1=30mm, d2=12mm

1x inlet to the insert: rounded, d=12mm

Measuring ranges

pressure: 500mmWC

jet radius: 0…10mm

Dimensions and weight

LxWxH: 400x400x830mm

Weight: approx. 18kg

quick overview :

Pressure losses in the flow from tanks are essentially the result of two processes: the jet deflection upon entry into the opening and the wall friction in the opening. As a result of the pressure losses the real discharge is smaller than the theoretical flow rate.

It determines these losses at different flow rates. Different diameters as well as inlet and outlet contours of the openings can be studied. Additionally, the contraction coefficient can be determined as a characteristic for different contours.

The experimental unit includes a transparent tank, a measuring device as well as a Pitot tube and twin tube manometers. An interchangeable insert is installed in the tank’s water outlet to facilitate the investigation of various openings. Five inserts with different diameters, inlet contours and outlet contours are provided along with the unit.

The issued water jet is measured using a measuring device. A Pitot tube detects the total pressure of the flow. The pressure difference (read on the manometer) is used to determine the velocity.

Learning Objectives/Experiments

Study of the outlet jet (diameter, velocity)

Determination of pressure losses and contraction coefficient for different outlet contours

Determination of flow rate at different discharge heads

Features

Determination of the diameter and velocity of the outlet jet

Study of openings with different inlet and outlet contours

Determining the contraction coefficient

Specification

Study of pressure losses in vertical flows from tanks

Determining the contraction coefficient for different contours and diameters

Tank with adjustable overflow

5 interchangeable inserts with different contours

Measuring device for determining the jet diameter

Pitot tube for determining the total pressure

Pressure display on twin tube manometers

Flow rate determined by base module

Water supply using base module or via laboratory supply

Technical data

Tank

capacity: approx. 13L

overflow height: max. 400mm

max. flow rate: 14L/min

Inserts

Inner diameters: d1=inlet, d2=outlet

1x cylindrical hole, d=12mm

1x outlet from the insert: cone d1=24mm, d2=12mm

1x inlet to the insert: orifice plate d1=24mm, d2=12mm

1x inlet to the insert: cone d1=30mm, d2=12mm

1x inlet to the insert: rounded, d=12mm

Measuring ranges

pressure: 500mmWC

jet radius: 0…10mm

Dimensions and weight

LxWxH: 400x400x830mm

Weight: approx. 18kg

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.