Wind Power Drive Trainer

Categories: Engineering Lab EquipmentModern wind turbines should be optimally adapted to the wind available at their location and allow efficient operating conditions. In addition to the wind rotor itself, components of the drive train s...

Product

Description

Modern wind turbines should be optimally adapted to the wind available at their location and allow efficient operating conditions. In addition to the wind rotor itself, components of the drive train such as the transmission and the electric generator are crucial.

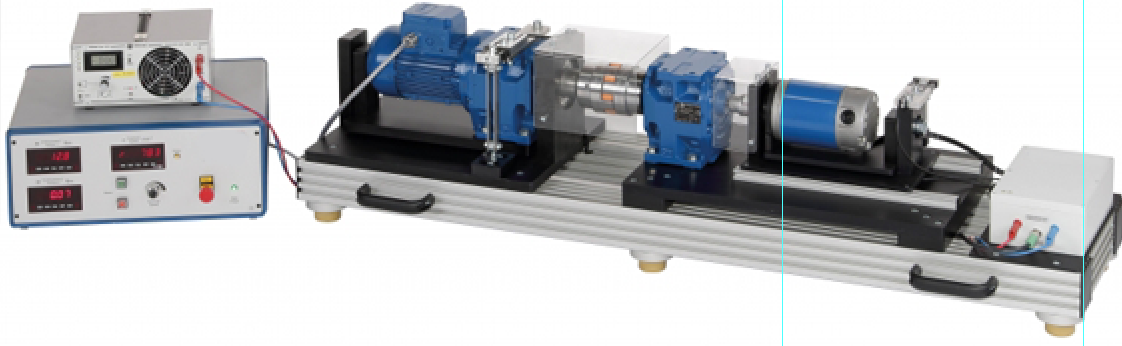

The experimental unit contains a typical wind power drive train at laboratory scale, which is driven by an electric motor. The motor enables low speeds with high torque. This simulates a typical slowly rotating wind rotor. The speed can be adjusted.

The drive train consists of the slow-rotating drive side, the fast-rotating generator side and a three-stage spur gear between the drive and the generator. The electrical load of the generator can be varied.The experiments with simulate typical operating conditions of a drive train. To do this, the electrical load of the generator and the speed of the drive motor are varied. This makes it possible to approximate operating points of a typical torque characteristic. The calculated characteristic results from the mechanical power of a wind rotor for a given wind speed.

Learning objectives/experiments

Conversion of rotational energy into electrical energy

Influence of torque and speed on the efficiency of the transmission

Influence of torque and speed on the efficiency of the generator

Influence of the typical torque characteristic of a wind rotor on the overall efficiency of the drive train

Specification

Experimental unit for measurements on a wind power drive train

Drive train with spur gear and DC generator

Low-speed drive motor with adjustable speed simulates wind rotor

Simulation of typical torque characteristics

DC generator with connections for electrical load

Adjustable load with switchable display for current or voltage

Sensors for generator speed and torques of the drive side and of the generator

Measuring amplifier with digital displays and control elements

Analogue outputs for transmitting the measured values for torque and speed

Technical data

DC generator

rated speed: 1100min-1

max. power: 150W

max. current: 10A

max. voltage: 28V

Spur gear

transmission ratio: 1:53

rated load capacity: 335Nm

rated efficiency: 94%

Drive motor

rated speed: 22min-1

speed range: 3…22min-1

rated power: 0,37kW

max. torque: 153Nm

Measuring ranges

speed: 0…1200min-1

torque: 0…200Nm

torque: 0…10Nm

current: 0,005…25A

voltage: 0…80V

230V, 50Hz, 1 phase

120V, 60Hz, 1 phase, 230V, 60Hz, 1 phase

quick overview :

Modern wind turbines should be optimally adapted to the wind available at their location and allow efficient operating conditions. In addition to the wind rotor itself, components of the drive train such as the transmission and the electric generator are crucial.

The experimental unit contains a typical wind power drive train at laboratory scale, which is driven by an electric motor. The motor enables low speeds with high torque. This simulates a typical slowly rotating wind rotor. The speed can be adjusted.

The drive train consists of the slow-rotating drive side, the fast-rotating generator side and a three-stage spur gear between the drive and the generator. The electrical load of the generator can be varied.The experiments with simulate typical operating conditions of a drive train. To do this, the electrical load of the generator and the speed of the drive motor are varied. This makes it possible to approximate operating points of a typical torque characteristic. The calculated characteristic results from the mechanical power of a wind rotor for a given wind speed.

Learning objectives/experiments

Conversion of rotational energy into electrical energy

Influence of torque and speed on the efficiency of the transmission

Influence of torque and speed on the efficiency of the generator

Influence of the typical torque characteristic of a wind rotor on the overall efficiency of the drive train

Specification

Experimental unit for measurements on a wind power drive train

Drive train with spur gear and DC generator

Low-speed drive motor with adjustable speed simulates wind rotor

Simulation of typical torque characteristics

DC generator with connections for electrical load

Adjustable load with switchable display for current or voltage

Sensors for generator speed and torques of the drive side and of the generator

Measuring amplifier with digital displays and control elements

Analogue outputs for transmitting the measured values for torque and speed

Technical data

DC generator

rated speed: 1100min-1

max. power: 150W

max. current: 10A

max. voltage: 28V

Spur gear

transmission ratio: 1:53

rated load capacity: 335Nm

rated efficiency: 94%

Drive motor

rated speed: 22min-1

speed range: 3…22min-1

rated power: 0,37kW

max. torque: 153Nm

Measuring ranges

speed: 0…1200min-1

torque: 0…200Nm

torque: 0…10Nm

current: 0,005…25A

voltage: 0…80V

230V, 50Hz, 1 phase

120V, 60Hz, 1 phase, 230V, 60Hz, 1 phase

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.