- Admin

- 0 Comments

Technical and Vocational Training Institutes enable young minds to carve a niche for themselves in the technical field. A technical and vocational educational training institute focuses on providing a learning environment that is more practical than theoretical. Technical Vocational and Education Training - TVET Lab Equipment is required to be of distinguished quality and abet in the learning process.

Technical Vocational and Educational Lab Equipment is the perfect choice by TVET Lab Equipment Manufacturers for technical and vocational education and training institutes for giving the young aspirants a platform to do research and experimentation. TVET Lab Instruments require adherence to the safety norms to prevent any mishap or accident.

Atico Lab Export is the name in the industry that has since its inception leading to be the top manufacturer and technical educational equipment lab equipment Suppliers. The sole purpose of developing, designing, and innovating Vocational Training Lab Equipment (TVET) is to suit the requirements of the curriculum designed by Technical & Vocational Training Institutes.

Ensuring Safety in Technical Vocational Training Labs (TVET)

Safety must always come first when working with Vocational Educational Training (VET) Lab Instruments. To reduce risks and ensure both students and educators remain protected, all relevant safety protocols must be strictly implemented within vocational training laboratories:

Ensuring Safety in Technical Vocational Training Labs

Ensuring safety when working with TVET Lab Instruments is of utmost importance. To minimize risks and protect both students and educators, vocational training laboratories must adhere strictly to these safety protocols:

Introduce comprehensive awareness programs to instructors, lab personnel and students regarding the potential dangers associated with handling technical equipment.

Maintain a strict discipline and decorum within the laboratory in order to minimize accidents.

Make sure that all TVET Lab Equipment supplied comes complete with an accessible, comprehensive instruction manual which should be read and followed carefully prior to being used.

Update and maintain an inventory list for students' and teachers' personal protective equipment (PPE).

Label and guard any equipment which could pose a potential threat.

Keep lab floors dry and free from slippery substances to avoid slips, trips and falls.

Prominently display safety reminders and operating instructions near all Technical Vocational Educational lab equipment.

Secure unstable lab equipment to floors.

Prevent potential electrical hazards, electrical equipment safely

Eye protection equipment must be used like goggles, safety glasses and shields must always be accessible when necessary.

Availability of first aid kit on hand in the laboratory, with emergency contact numbers displayed clearly for quick and easy access.

Technical Vocational Educational Lab Equipment Uses and Benefits

Atico Lab Export has endeavored its best to support the growing demands of the technical education sector. The technical and vocational education and training are growing manifolds and we must provide them with the latest Vocational Training Lab Equipment to sustain their learning. In the current global workforce market, there is a high demand for experienced professionals that have thorough technical knowledge and expertise. Technical and Vocational education is a branch of technical studies that require experiential learning.

It is imperative that hands-on learning is aided with technical education training equipment with the latest technology and unrivaled quality. TVET Lab Equipment Exporters have deeply understood the market requirements and designed, developed, and exported TVET Lab Equipment that enables gaining knowledge of fundamentals of applied sciences by students all over the world.

To view our entire range of equipment along with their product description, kindly visit our website and leave a message.

21 TVET Lab Equipment List and Their Significance to Practical Training.

1. Multimeter

A multimeter is a must-have, piece of equipment in measuring voltage (V), current (I), and resistance (R) in an electric circuit. In TVET labs pertaining electrical engineering, electronics, and automotive technology, multimeters help learners perform circuit tests, fault diagnosis, and ensure precision in electrical component checks.

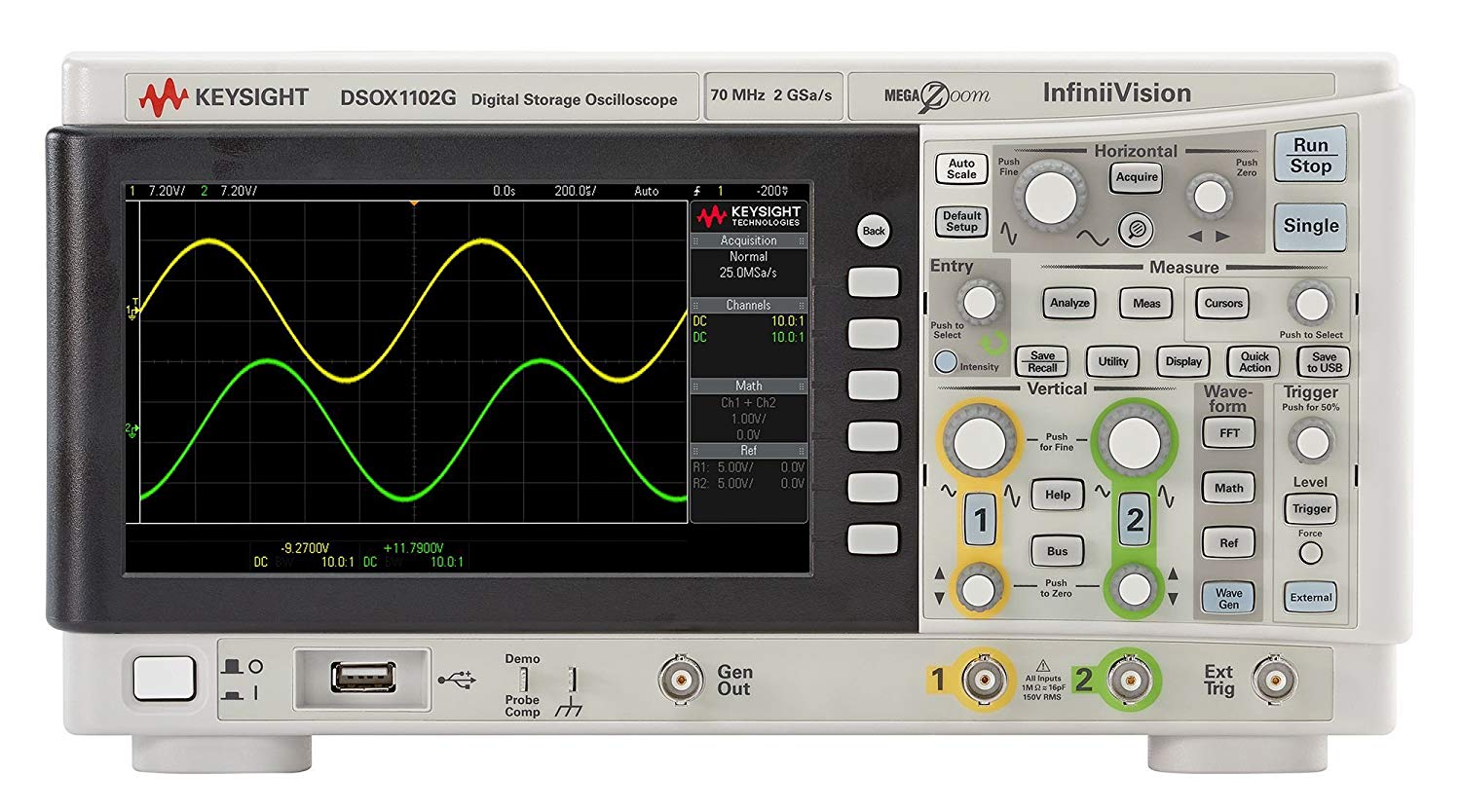

2. Oscilloscope

In addition to serving as a signal display, the oscilloscope has other uses such as measuring the frequency of signals, amplitude, and noise. A modern electronics and telecommunication laboratory would be incomplete without this implement. This apparatus is essential to grasping the operation of various circuits and identifying problems in intricate electronic systems.

3. Hydraulic Trainer Kit

Found in civils and mechanical engineering laboratories, the hydraulic trainer kit shows how certain principles of fluid mechanics and hydraulics operates. Students understand hydraulic systems utilized in construction, manufacturing, and automotive industries along with fluid pressure and flow rates.

4. Lathe Machine

The lathe machine is a core piece of equipment in workshops dealing with metalworking and mechanics. Students can do operations such as cutting, sanding, drilling, and turning into precise shapes and components from metal and wood materials. Mastering the lathe machine is essential to career paths in machining and manufacturing.

5. CNC Machine

Computer Numerical Control (CNC) machines are representative of new age technologies in the production industry. Teaching pupils in programming and operating automated machine tools used for precise fabrication is made possible with CNC machines in TVET laboratories. This technology marks the transition from conventional machining to modern practices of machining in Industry 4.0.

6. Power Supply Unit

Found in robotics, electronics, and electrical engineering labs, The power supply unit is needed for adjustable and stable electricity. While conducting experiments, The power supply unit ensures components and circuits are given the appropriate voltage and current which provides a safe environment for controlled testing.

7. Vernier Caliper

A vernier caliper enables the measuring of length, diameter, and depth with extreme precision. In mechanical, manufacturing, and quality control labs, where products need to be measured and evaluated, this tool is indispensable.

8. Soldering Station

Every electronics lab requires a soldering station to aid in the assembly and repair of circuit boards. Students acquire the ability to fuse parts through soldering to create dependable electrical connections, hence developing skills in practical electronics assembly.

9. Digital Microscope

With the aid of a digital microscope, students studying biology, material science, and even electronics are able to conduct more in-depth examinations of smaller specimens. It allows them to observe and study micro structures and circuits in detail, thereby integrating theory with observation.

10. Solar Panel Trainer Kit

In the field of renewable energy, the solar panel trainer kit teaches students about photovoltaic technology and principles of energy conversion. From an industry perspective, trainees learn the practical aspects of solar energy systems, including wiring solar panels and measuring power output, contributing to global sustainability objectives.

11. Refrigeration Trainer

The refrigeration trainer is an important tool for HVAC (Heating, Ventilation, and Air Conditioning) courses. It reproduces actual works of refrigeration cycles so students may learn the fundamentals of cooling, compression, heat exchange, and preparatory processes needed in appliance repair and climate control systems careers.

12. Tensile Testing Machine

The tenslie testing machine employed in civil engineering and materials science laboratories is used for measuring the strength and elasticity of materials. This information is necessary for assessing the suitability of the material and structural integrity in construction and manufacturing.

13. Welding Machine

Welding machine is basic equipment for training in fabrication and metalwork. It provides instruction in various welding methods, which include; arc welding, MIG and TIG, thus equipping students with skills to accurately and skillfully join metals essential in construction, automotive and manufacturing industries.

14. Pneumatic Trainer

This trainer facilitates the learning of systems that use compressed air as well as their application in automation and manufacturing. Students study valves, cylinders, and other controlling devices, practicing modern industrial automation.

15. Electronic Breadboard

An electronic breadboard is defined as a portable workspace for preparing and evaluating circuits in their prototypical forms. In academic settings, they are used in teaching robotics and electronics and in troubleshooting and developing projects.

16. Boiler Simulator

This simulator supports practical instruction within the disciplines of safety mechanisms, boiler operation, and thermodynamics. There is no other educational equipment that allows for a complete understanding of power generation and steam systems without using real boilers.

17. Digital Tachometer

These devices are also vital in mechanical and automotive training labs, where accurate measuring of machine operating speeds is key to assessing their performance and maintenance needs. A digital tachometer measures rotational speeds such as those found on shafts or disks in motors and engines.

18. Robotics Kit

These permits the students to assemble control systems and instruction devices and even program them, providing hands on experience in automation, control systems, and software engineering. Robotics Kits os [sic] combines with motors and sensors to facilitate building programmable robots.

19. Fuel Injection Trainer

As a part of a automotive and mechanical training, the fuel injection trainer shows internal combustion engines [sic] fuel injection systems function. It improves the learner’s comprehension of engine operating efficiency, emission control, and maintenance activities.

20. Water Testing Kit

In the civil engineering and environmental science laboratories, the water testing kit is used for determining the pH level, turbidity, and other water contaminants. This thus, equips learners for the workforce in public health and environmental safeguarding.

21. Thermometer and Hygrometer

These instruments are important in meteorology as well as other environmental studies. While reading temperature, a thermometer also records humidity levels and thus enables students to learn the weather and the environment.

Conclusion

A well-established TVET laboratory is important for the integration of theory and practice for learners in many fields of a particular technology. The 21 pieces of equipment which are stated above serve as a primary basis for the hands-on training that is needed. This will sharpen the students’ skills and increase their chances of employment in the rapidly developing areas of technology.

There is no doubt that the institutions that acquire these basic items will ensure that their students are well equipped to master their areas of the technology, attract, and excel in employment of their choice. Every equipment could be viewed as a building block for the students to acquire practical skills and be prepared to enter the world of work