Absorption Pilot Plant (Medium Line)

Categories:This absorption unit has been designed to explain the principles of gas-liquid absorption, and for the practical training on absorption plants. The absorption packed column of borosilicate glass is in...

Product

Description

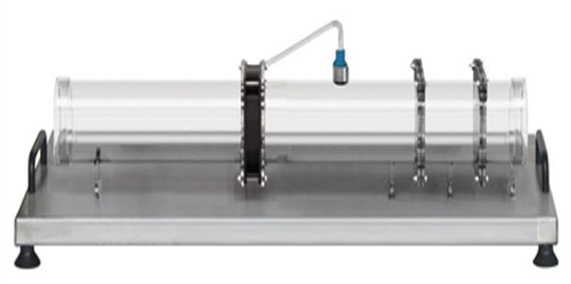

This absorption unit has been designed to explain the principles of gas-liquid absorption, and for the practical training on absorption plants. The absorption packed column of borosilicate glass is installed vertically on a framework of stainless steel with castors. This column is packed with glass Raschig rings for gas absorption. The liquid used in the process is stored in a tank of stainless steel and it is sent to the column top by a centrifugal pump of stainless steel. Then the liquid flows down the column wetting the packing and returns to the tank. A variable area flowmeter enables to measure the flow rate of liquid. Generally the gas to be absorbed is carbon dioxide, stored in a cylinder (not included in the equipment) placed near the unit. The gas crosses a variable area flowmeter and it is mixed with an air flow of known flow rate coming from a compressor installed on the framework. Then the composition of the mixture entering the column is known and it can be modified easily. This gaseous mixture enters the column bottom, then it mounts the column meeting the liquid falling down the column in counter flow. Some test points available at the top, at the centre and at the bottom of the column enable to measure the pressure drop on the packing with some pressure gauges. These test points can also be used to sample the gaseous phase. The content of carbon dioxide in gaseous phase is determined by an Hempl apparatus. Flowmeters, pressure gauges and gas analysis system are installed at a suitable height for operation.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Study of the main principles of the absorption of a gas into a liquid through a packed column

• Demonstration of quantitative methods of analysis of gaseous and liquid phase

• Mass balance for an absorption column

• Determination of mass transfer coefficient

• Study of hydrodynamic characteristics of a packed column

• Determination of flooding and loading points

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Absorption column of borosilicate glass DN80, consisting of 2 sections of 750 mm, with inside diameter of 80 mm, with 10 mm Raschig rings packing of borosilicate glass

• Feeding tank of AISI 304 stainless steel, with volume of 50 litres

• Centrifugal feeding pump of AISI 316 stainless steel, Qmax = 28 l/min, Hmax = 1 bar

• Rotary compressor, Qmax = 10 m3/h, Pmax = 0.8 bar

• Flowmeter for water, with range of 60-600 l/h

• Flowmeter for CO2 with range of 2-22 Nl/min

• Flowmeter for air with range of 20-200 Nl/min

• 2 differential U-tube pressure gauges, with range of 0-500 mm H2O

• Hempl apparatus for gas analysis

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

quick overview :

This absorption unit has been designed to explain the principles of gas-liquid absorption, and for the practical training on absorption plants. The absorption packed column of borosilicate glass is installed vertically on a framework of stainless steel with castors. This column is packed with glass Raschig rings for gas absorption. The liquid used in the process is stored in a tank of stainless steel and it is sent to the column top by a centrifugal pump of stainless steel. Then the liquid flows down the column wetting the packing and returns to the tank. A variable area flowmeter enables to measure the flow rate of liquid. Generally the gas to be absorbed is carbon dioxide, stored in a cylinder (not included in the equipment) placed near the unit. The gas crosses a variable area flowmeter and it is mixed with an air flow of known flow rate coming from a compressor installed on the framework. Then the composition of the mixture entering the column is known and it can be modified easily. This gaseous mixture enters the column bottom, then it mounts the column meeting the liquid falling down the column in counter flow. Some test points available at the top, at the centre and at the bottom of the column enable to measure the pressure drop on the packing with some pressure gauges. These test points can also be used to sample the gaseous phase. The content of carbon dioxide in gaseous phase is determined by an Hempl apparatus. Flowmeters, pressure gauges and gas analysis system are installed at a suitable height for operation.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Study of the main principles of the absorption of a gas into a liquid through a packed column

• Demonstration of quantitative methods of analysis of gaseous and liquid phase

• Mass balance for an absorption column

• Determination of mass transfer coefficient

• Study of hydrodynamic characteristics of a packed column

• Determination of flooding and loading points

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Absorption column of borosilicate glass DN80, consisting of 2 sections of 750 mm, with inside diameter of 80 mm, with 10 mm Raschig rings packing of borosilicate glass

• Feeding tank of AISI 304 stainless steel, with volume of 50 litres

• Centrifugal feeding pump of AISI 316 stainless steel, Qmax = 28 l/min, Hmax = 1 bar

• Rotary compressor, Qmax = 10 m3/h, Pmax = 0.8 bar

• Flowmeter for water, with range of 60-600 l/h

• Flowmeter for CO2 with range of 2-22 Nl/min

• Flowmeter for air with range of 20-200 Nl/min

• 2 differential U-tube pressure gauges, with range of 0-500 mm H2O

• Hempl apparatus for gas analysis

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.