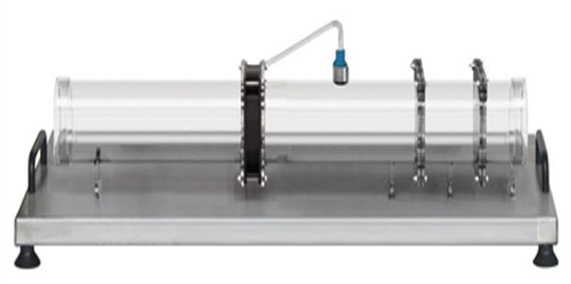

Batch Distillation Pilot Plant (Large Line)

Categories:The distillation column is completely made of glass and it consists of a reboiler, of a column with steel mesh packing and of a condenser with reflux valve and head. The distillate is collected into a...

Product

Description

The distillation column is completely made of glass and it consists of a reboiler, of a column with steel mesh packing and of a condenser with reflux valve and head. The distillate is collected into a glass tank after being cooled by a heat exchanger. The automated version is equipped with two PID controllers for controlling the feed pre-heating temperature, the flow rate of the condenser cooling water and the level of vacuum in the plant, automatically.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Distillation of different mixtures (water/ethanol, water/methanol, methanol/propanol, etc...) versus the variation of the following operational parameters:

- reflux ratio

- reboiler heating power

- feeding composition

- residual pressure

• Mass balance

• Energy balance

• Flooding

• Calculation of the number of theoretical trays

• Automatic flow, pressure and temperature control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Distillation column of borosilicate glass, DN 50, h = 1100 mm, with packing of AISI 316 stainless steel mesh

• Reflux head of borosilicate glass equipped with solenoid valve for the control of reflux ratio

• Over head condenser of borosilicate glass, with exchange surface of 0.4 m2

• Reboiler of borosilicate glass, with capacity of 5 l, equipped with quartz-sheathed electric resistor of 2.5 kW

• Vacuum gauge of AISI 304 stainless steel, with range of -1 to 0 bar

• 2 programmable timers for the control of reflux ratio

• 8 thermo-resistances Pt 100, with sheath of AISI 316 stainless steel

• 8 electronic temperature indicators

• Electronic differential pressure transmitter (between column top and bottom) of AISI 316 stainless steel , with range of 0 to 200 mm H2O, 4-20 mA output signal

• Board-type electronic indicator of the measure of differential pressure

• 2 graduated vessels of borosilicate glass for collecting the distillate, with capacity of 1 l

• Tube-in-tube heat exchanger of stainless steel for cooling the distillate

• Liquid-ring vacuum pump (P = 0.7 kW), equipped with air/water separator and check valve

• Thyristor unit for controlling the heating power

• Flowmeter of AISI 304 stainless steel for measuring the flow rate crossing the condenser: range of 0 to 250 l/h

• Piping and valves of AISI 304 and 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the technical specifications, this model also includes the following additional items:

• Flowmeter of AISI 304 stainless steel for measuring the flow rate to the condenser, 4-20 mA output, range of 0 to 250 l/h

• Electronic absolute pressure (in column) transmitter of AISI 316 stainless steel, range of 0 to 1000 mbar, 4-20 mA output signal

• Interface for the connection with PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the Technical specifications, this model also includes the following additional items:

• Flowmeter of AISI 304 stainless steel for measuring the flow rate to the condenser, 4-20 mA output signal, range of 0 to 250 l/h

• Pneumatic control valve, DN 15 of AISI 316 stainless steel, Cv = 2.5

• Electro-pneumatic converter 4 to 20 mA/0.2 to 1 bar

• Electronic absolute pressure (in column) transmitter of AISI 316 stainless steel, range of 0 to 1000 mbar, 4-20 mA output signal

• 2 microprocessor multi-loop digital controllers, with 2 PID control loops (flow rate of water to the condenser and residual pressure, input and output signals of 4 to 20 mA

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from the PID controller, real-time trend and historical trend

quick overview :

The distillation column is completely made of glass and it consists of a reboiler, of a column with steel mesh packing and of a condenser with reflux valve and head. The distillate is collected into a glass tank after being cooled by a heat exchanger. The automated version is equipped with two PID controllers for controlling the feed pre-heating temperature, the flow rate of the condenser cooling water and the level of vacuum in the plant, automatically.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Distillation of different mixtures (water/ethanol, water/methanol, methanol/propanol, etc...) versus the variation of the following operational parameters:

- reflux ratio

- reboiler heating power

- feeding composition

- residual pressure

• Mass balance

• Energy balance

• Flooding

• Calculation of the number of theoretical trays

• Automatic flow, pressure and temperature control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Distillation column of borosilicate glass, DN 50, h = 1100 mm, with packing of AISI 316 stainless steel mesh

• Reflux head of borosilicate glass equipped with solenoid valve for the control of reflux ratio

• Over head condenser of borosilicate glass, with exchange surface of 0.4 m2

• Reboiler of borosilicate glass, with capacity of 5 l, equipped with quartz-sheathed electric resistor of 2.5 kW

• Vacuum gauge of AISI 304 stainless steel, with range of -1 to 0 bar

• 2 programmable timers for the control of reflux ratio

• 8 thermo-resistances Pt 100, with sheath of AISI 316 stainless steel

• 8 electronic temperature indicators

• Electronic differential pressure transmitter (between column top and bottom) of AISI 316 stainless steel , with range of 0 to 200 mm H2O, 4-20 mA output signal

• Board-type electronic indicator of the measure of differential pressure

• 2 graduated vessels of borosilicate glass for collecting the distillate, with capacity of 1 l

• Tube-in-tube heat exchanger of stainless steel for cooling the distillate

• Liquid-ring vacuum pump (P = 0.7 kW), equipped with air/water separator and check valve

• Thyristor unit for controlling the heating power

• Flowmeter of AISI 304 stainless steel for measuring the flow rate crossing the condenser: range of 0 to 250 l/h

• Piping and valves of AISI 304 and 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the technical specifications, this model also includes the following additional items:

• Flowmeter of AISI 304 stainless steel for measuring the flow rate to the condenser, 4-20 mA output, range of 0 to 250 l/h

• Electronic absolute pressure (in column) transmitter of AISI 316 stainless steel, range of 0 to 1000 mbar, 4-20 mA output signal

• Interface for the connection with PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the Technical specifications, this model also includes the following additional items:

• Flowmeter of AISI 304 stainless steel for measuring the flow rate to the condenser, 4-20 mA output signal, range of 0 to 250 l/h

• Pneumatic control valve, DN 15 of AISI 316 stainless steel, Cv = 2.5

• Electro-pneumatic converter 4 to 20 mA/0.2 to 1 bar

• Electronic absolute pressure (in column) transmitter of AISI 316 stainless steel, range of 0 to 1000 mbar, 4-20 mA output signal

• 2 microprocessor multi-loop digital controllers, with 2 PID control loops (flow rate of water to the condenser and residual pressure, input and output signals of 4 to 20 mA

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from the PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.