Biodiesel Production Pilot Plant

Categories: Chemical Engineering Manufacturer and SupplierBiodiesel is a liquid fuel obtained by transesterification from renewable raw materials such as, for instance, vegetable oils or animal fats. If compared to fossil fuels, this type of fuel offers a lo...

Product

Description

Biodiesel is a liquid fuel obtained by transesterification from renewable raw materials such as, for instance, vegetable oils or animal fats. If compared to fossil fuels, this type of fuel offers a lot of advantages:

• Very low content of sulphur (< 0.001%) that provokes the phenomenon of acid rains

• Reduction of dust emissions down to 50%

• Absence of benzene and of other carcinogenic components

• As it has a high flash point, it is not classified as dangerous material, consequently it can be handled easily and safely

• High biodegradation (in case of dispersion it does not pollute)

• High lubricating power (it reduces the wear of engines)

• It develops a closed loop of CO2 (the quantity of CO2 released by its combustion is equal to that absorbed by plants from the air during their growing process).

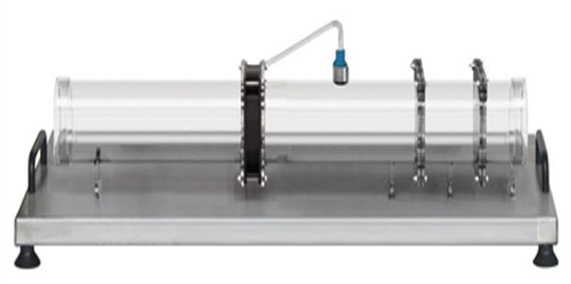

This unit is mainly equipped with a multi-function reactor that enables to carry out all the typical operations of biodiesel production: esterification, transesterification, washing and restoring of methanol.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Transesterification of a vegetable oil

• Separation of glycerine

• Washing of biodiesel

• Restoring methanol

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Multi-function reactor of borosilicate glass and AISI 304 stainless steel, with capacity of 18 litres, equipped with motor-driven stirrer and condenser

• Heating system by electric heaters, provided with thermostat

• Tank of borosilicate glass and AISI 304 stainless steel for reagent/catalyst, including stirring system

• 2 restoring tanks of borosilicate glass

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ONOFF signals, analog signals coming from PID controller, real time

trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

quick overview :

Biodiesel is a liquid fuel obtained by transesterification from renewable raw materials such as, for instance, vegetable oils or animal fats. If compared to fossil fuels, this type of fuel offers a lot of advantages:

• Very low content of sulphur (< 0.001%) that provokes the phenomenon of acid rains

• Reduction of dust emissions down to 50%

• Absence of benzene and of other carcinogenic components

• As it has a high flash point, it is not classified as dangerous material, consequently it can be handled easily and safely

• High biodegradation (in case of dispersion it does not pollute)

• High lubricating power (it reduces the wear of engines)

• It develops a closed loop of CO2 (the quantity of CO2 released by its combustion is equal to that absorbed by plants from the air during their growing process).

This unit is mainly equipped with a multi-function reactor that enables to carry out all the typical operations of biodiesel production: esterification, transesterification, washing and restoring of methanol.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Transesterification of a vegetable oil

• Separation of glycerine

• Washing of biodiesel

• Restoring methanol

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Multi-function reactor of borosilicate glass and AISI 304 stainless steel, with capacity of 18 litres, equipped with motor-driven stirrer and condenser

• Heating system by electric heaters, provided with thermostat

• Tank of borosilicate glass and AISI 304 stainless steel for reagent/catalyst, including stirring system

• 2 restoring tanks of borosilicate glass

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ONOFF signals, analog signals coming from PID controller, real time

trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.