Bioethanol Production Pilot Plant

Categories:Bioethanol is ethanol obtained from the fermentation of agricultural products and it is mainly used as alternative fuel. This equipment enables to carry out a realistic test of conversion of starch in...

Product

Description

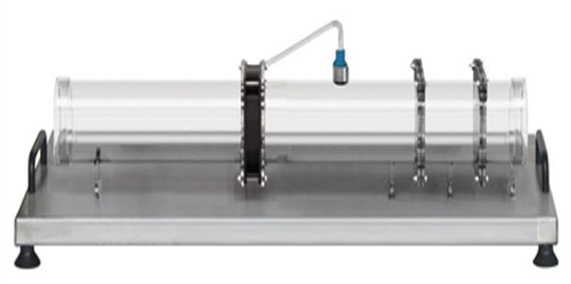

Bioethanol is ethanol obtained from the fermentation of agricultural products and it is mainly used as alternative fuel. This equipment enables to carry out a realistic test of conversion of starch into ethanol through all the phases of this process in a multi-function reactor that can implement liquefaction, scarification, fermentation and distillation.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Gelification

• Liquefaction with α-amylase

• Saccarification with glucoamylase

• Fermentation with yeast

• Separation of ethanol by distillation

• Automatic temperature control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Multi-function reactor of AISI 304 stainless steel, with capacity of 13 litres, equipped with:

- stirrer of AISI 304 stainless steel, with mechanical seal, turning at variable speed

- baffles

- sight glass

- cooling/heating coil

- insulation with sheet steel

- thrmoresistor Pt100

- sensor for measuring pH

- safety valve

- distillation column of borosilicate glass with bubble cap trays and 2 thermoresistances Pt100

- condenser of AISI 304 stainless steel with 2 thermoresistances Pt100

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Pneumatic valve of AISI 316 stainless steel for controlling the flow rate of steam

• Pneumatic valve of AISI 316 stainless steel for controlling the flow rate of cooling water

• 2 electro-pneumatic converters 4 to 20 mA/ 0.2 to 1 bar

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

quick overview :

Bioethanol is ethanol obtained from the fermentation of agricultural products and it is mainly used as alternative fuel. This equipment enables to carry out a realistic test of conversion of starch into ethanol through all the phases of this process in a multi-function reactor that can implement liquefaction, scarification, fermentation and distillation.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Gelification

• Liquefaction with α-amylase

• Saccarification with glucoamylase

• Fermentation with yeast

• Separation of ethanol by distillation

• Automatic temperature control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Multi-function reactor of AISI 304 stainless steel, with capacity of 13 litres, equipped with:

- stirrer of AISI 304 stainless steel, with mechanical seal, turning at variable speed

- baffles

- sight glass

- cooling/heating coil

- insulation with sheet steel

- thrmoresistor Pt100

- sensor for measuring pH

- safety valve

- distillation column of borosilicate glass with bubble cap trays and 2 thermoresistances Pt100

- condenser of AISI 304 stainless steel with 2 thermoresistances Pt100

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Pneumatic valve of AISI 316 stainless steel for controlling the flow rate of steam

• Pneumatic valve of AISI 316 stainless steel for controlling the flow rate of cooling water

• 2 electro-pneumatic converters 4 to 20 mA/ 0.2 to 1 bar

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.