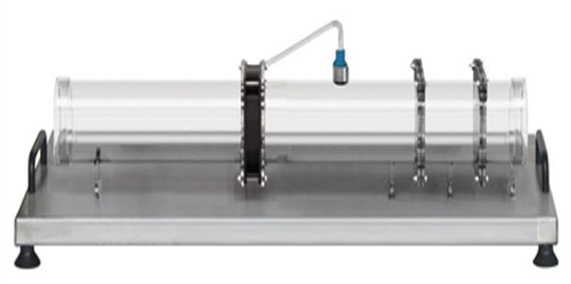

Continuous Distillation Pilot Plant

Categories:The solution having to be distilled, stored in a tank of plastic material, is sent to the distillation column by a metering pump after crossing a pre-heating exchanger. The distillation column is comp...

Product

Description

The solution having to be distilled, stored in a tank of plastic material, is sent to the distillation column by a metering pump after crossing a pre-heating exchanger. The distillation column is completely of glass and it consists of a reboiler, of a sieve-tray column and of a condenser with reflux head and valve. The bottom product and the distillate are collected into two tanks after being cooled by two heat exchangers.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Distillation of different mixtures (water / ethanol, water /methanol, methanol / propanol, etc...) at atmospheric pressure, versus the variation of the following operational parameters:

- reflux ratio

- feeding flow rate

- feeding composition

• Mass balance

• Energy balance

• Flooding

• Calculation of the number of theoretical trays

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Distillation column of borosilicate glass with 7 sieve trays, DN50, h = 600 mm

• Reboiler of borosilicate glass, with capacity of 5 l, provided with electric heater of 1600 W

• Condenser of borosilicate glass with reflux head

• Feeding tank of plastic material, with capacity of 5 l

• Tank of borosilicate glass with capacity of 1 l, for the collection of distillate

• Tank of plastic material, with capacity of 5 l, for the collection of bottom product

• 3 tube-in-tube heat exchangers of AISI 304 stainless steel

• Metering pump with flow rate of 0 to 8.5 l/h

• 6 digital thermometers with sheath of stainless steel

• Thyristor unit for controlling the power of the reboiler electric heater

• 2 programmable timers for the control of reflux ratio

• Variable area flowmeter of glass and steel, with range of 20 to 200 l/h

• Switchboard IP55, complying with EC standards

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

quick overview :

The solution having to be distilled, stored in a tank of plastic material, is sent to the distillation column by a metering pump after crossing a pre-heating exchanger. The distillation column is completely of glass and it consists of a reboiler, of a sieve-tray column and of a condenser with reflux head and valve. The bottom product and the distillate are collected into two tanks after being cooled by two heat exchangers.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Distillation of different mixtures (water / ethanol, water /methanol, methanol / propanol, etc...) at atmospheric pressure, versus the variation of the following operational parameters:

- reflux ratio

- feeding flow rate

- feeding composition

• Mass balance

• Energy balance

• Flooding

• Calculation of the number of theoretical trays

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Distillation column of borosilicate glass with 7 sieve trays, DN50, h = 600 mm

• Reboiler of borosilicate glass, with capacity of 5 l, provided with electric heater of 1600 W

• Condenser of borosilicate glass with reflux head

• Feeding tank of plastic material, with capacity of 5 l

• Tank of borosilicate glass with capacity of 1 l, for the collection of distillate

• Tank of plastic material, with capacity of 5 l, for the collection of bottom product

• 3 tube-in-tube heat exchangers of AISI 304 stainless steel

• Metering pump with flow rate of 0 to 8.5 l/h

• 6 digital thermometers with sheath of stainless steel

• Thyristor unit for controlling the power of the reboiler electric heater

• 2 programmable timers for the control of reflux ratio

• Variable area flowmeter of glass and steel, with range of 20 to 200 l/h

• Switchboard IP55, complying with EC standards

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 2 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.