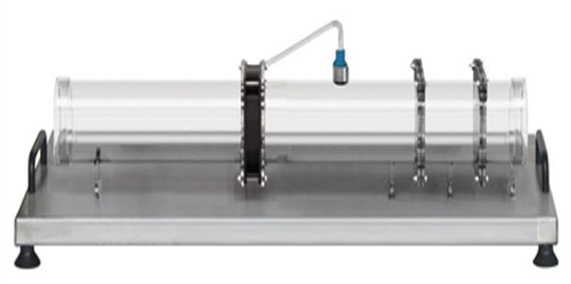

Continuous Reaction Pilot Plant (PFR)

Categories: Chemical Engineering Manufacturer and SupplierThis unit is equipped with a tubular reactor thermostated and fed by two gear pumps; the flow rate of reagents is measured by two magnetic flowmeters. The study of kinetics is carried out versus the v...

Product

Description

This unit is equipped with a tubular reactor thermostated and fed by two gear pumps; the flow rate of reagents is measured by two magnetic flowmeters. The study of kinetics is carried out versus the variation of conductivity at the reactor outlet. The automated version is equipped with PID controller for the automatic control of reaction temperature and of the flow rate of reagents.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of reaction kinetics

• Reaction thermodynamics

• Mass and energy balance

• Automatic temperature and flow control with PID controller

• Plant supervision by P.C.

• Exercises than can be carried out:

- kinetics of hydrolysis of ethyl acetate

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• 2 feeding tanks of AISI 316 stainless steel with capacity of 10 l

• Tank of AISI 316 stainless steel with capacity of 20 l, for collecting the product

• Tubular reactor, with capacity of 2 l and jacket of AISI 304 stainless steel

• Electronic conductivity meter

• 2 variable area flow meters

• Tube-in-tube heat exchanger at the reactor outlet

• Tank of borosilicate glass, with capacity of 2 l, for the neutralization solution

• 2 gear pumps of AISI 316 stainless steel

• Metering pump for the neutralization solution

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• 2 magnetic induction flow meters

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 1 kVA (Other voltage and frequency on request)

quick overview :

This unit is equipped with a tubular reactor thermostated and fed by two gear pumps; the flow rate of reagents is measured by two magnetic flowmeters. The study of kinetics is carried out versus the variation of conductivity at the reactor outlet. The automated version is equipped with PID controller for the automatic control of reaction temperature and of the flow rate of reagents.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of reaction kinetics

• Reaction thermodynamics

• Mass and energy balance

• Automatic temperature and flow control with PID controller

• Plant supervision by P.C.

• Exercises than can be carried out:

- kinetics of hydrolysis of ethyl acetate

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• 2 feeding tanks of AISI 316 stainless steel with capacity of 10 l

• Tank of AISI 316 stainless steel with capacity of 20 l, for collecting the product

• Tubular reactor, with capacity of 2 l and jacket of AISI 304 stainless steel

• Electronic conductivity meter

• 2 variable area flow meters

• Tube-in-tube heat exchanger at the reactor outlet

• Tank of borosilicate glass, with capacity of 2 l, for the neutralization solution

• 2 gear pumps of AISI 316 stainless steel

• Metering pump for the neutralization solution

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• 2 magnetic induction flow meters

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

• Power supply: 230 Vac 50 Hz single-phase - 1 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.