Distillation Column Simulator

Categories: Chemical Engineering Manufacturer and SupplierThis unit consists of a column of transparent plastic material equipped with two sieve trays and of a bubble cap tray. The upper sieve tray will distribute gas and liquid onto the bubble cap tray inst...

Product

Description

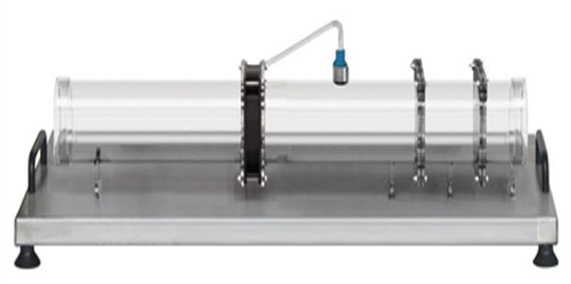

This unit consists of a column of transparent plastic material equipped with two sieve trays and of a bubble cap tray. The upper sieve tray will distribute gas and liquid onto the bubble cap tray installed below. Three pressure taps along the column supply the pressure

drops to the bubble cap tray and to the lower sieve tray. The unit also includes a tank for the water, a pump that recycles the water to the column top, and a blower connected with the column bottom. The water flow rate is measured by a variable area flowmeter,

whereas the air flow rate is measured by an electronic anemometer. The big diameter of the column (600 mm) enables to observe

the operation of the different types of tray easily in the various testing conditions.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Design of trays of distillation columns

• Operation of trays of distillation columns

• Hydraulics of bubble cap trays and of sieve trays

TECHNICAL SPECIFICATIONS:

• Framework of stainless AISI 304 with castors

• Column of transparent plastic, diameter = 600 mm, with two sieve trays, a bubble cap tray and three pressure taps

• 2 differential manometers

• Feeding tank of AISI 304 stainless steel with capacity of 100 l

• Centrifugal pump of AISI 304 stainless steel

• Variable area flow meter

• Centrifugal fan

• Switchboard IP55

• Power supply: 230 Vac 50 Hz single-phase - 3 kVA (Other voltage and frequency on request)

quick overview :

This unit consists of a column of transparent plastic material equipped with two sieve trays and of a bubble cap tray. The upper sieve tray will distribute gas and liquid onto the bubble cap tray installed below. Three pressure taps along the column supply the pressure

drops to the bubble cap tray and to the lower sieve tray. The unit also includes a tank for the water, a pump that recycles the water to the column top, and a blower connected with the column bottom. The water flow rate is measured by a variable area flowmeter,

whereas the air flow rate is measured by an electronic anemometer. The big diameter of the column (600 mm) enables to observe

the operation of the different types of tray easily in the various testing conditions.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Design of trays of distillation columns

• Operation of trays of distillation columns

• Hydraulics of bubble cap trays and of sieve trays

TECHNICAL SPECIFICATIONS:

• Framework of stainless AISI 304 with castors

• Column of transparent plastic, diameter = 600 mm, with two sieve trays, a bubble cap tray and three pressure taps

• 2 differential manometers

• Feeding tank of AISI 304 stainless steel with capacity of 100 l

• Centrifugal pump of AISI 304 stainless steel

• Variable area flow meter

• Centrifugal fan

• Switchboard IP55

• Power supply: 230 Vac 50 Hz single-phase - 3 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.