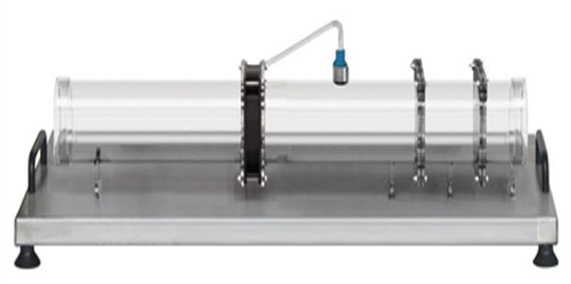

Fixed and Fluidized Beds Apparatus

Categories: Chemical Engineering Manufacturer and SupplierThis equipment has been designed to study how a water or air flow crosses fixed and fluidized beds of solid particles and to observe the difference between “aggregative” and “particulate” fluidization...

Product

Description

This equipment has been designed to study how a water or air flow crosses fixed and fluidized beds of solid particles and to observe the difference between “aggregative” and “particulate” fluidization. Moreover this unit can be used to obtain experimental data of fluidization of real beds (catalyst beds, filtration beds, etc...).

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Pressure drop in fixed or fluidized bed with water or air

• Ergun equation and simplified forms (Carman-Kozeny and Burke-Plummer equations)

• Determining bed porosity

• Checking the different types of fluidization (particulate and aggregative)

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel

• 2 measuring pipes of transparent Plexiglas with support and filter of sintered steel; height = 550 mm, inside diameter = 44 mm, range: 0 to 500 mm

• 2 beds of material with different granulometry

• Double-diaphragm compressor, Qmax = 39 l/min, Pmax = 2 bar, with air storing reservoirs

• Water tank of AISI 304 stainless steel with capacity of 6 litres

• Pump of AISI 316 stainless steel, Qmax = 1500 l/h, Hmax = 2 bar

• Variable area flowmeter with control micro-valve and range of 7 to 70 l/h

• Variable area flowmeter with control micro-valve and range of 300 to 1700 Nl/h

• Double-pipe pressure gauge, with range of 0 to 500 mmH2O

• U-tube pressure gauge for air, with range of 0 to 300 mmH2O

• Safety valve adjusted at 0.5 bar

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

quick overview :

This equipment has been designed to study how a water or air flow crosses fixed and fluidized beds of solid particles and to observe the difference between “aggregative” and “particulate” fluidization. Moreover this unit can be used to obtain experimental data of fluidization of real beds (catalyst beds, filtration beds, etc...).

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Pressure drop in fixed or fluidized bed with water or air

• Ergun equation and simplified forms (Carman-Kozeny and Burke-Plummer equations)

• Determining bed porosity

• Checking the different types of fluidization (particulate and aggregative)

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel

• 2 measuring pipes of transparent Plexiglas with support and filter of sintered steel; height = 550 mm, inside diameter = 44 mm, range: 0 to 500 mm

• 2 beds of material with different granulometry

• Double-diaphragm compressor, Qmax = 39 l/min, Pmax = 2 bar, with air storing reservoirs

• Water tank of AISI 304 stainless steel with capacity of 6 litres

• Pump of AISI 316 stainless steel, Qmax = 1500 l/h, Hmax = 2 bar

• Variable area flowmeter with control micro-valve and range of 7 to 70 l/h

• Variable area flowmeter with control micro-valve and range of 300 to 1700 Nl/h

• Double-pipe pressure gauge, with range of 0 to 500 mmH2O

• U-tube pressure gauge for air, with range of 0 to 300 mmH2O

• Safety valve adjusted at 0.5 bar

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.