Heat Exchangers Apparatus

Categories: Chemical Engineering Manufacturer and SupplierThis equipment consists of a service unit that supplies the necessary utilities and measuring instruments to carry out tests on five types of heat exchangers: tube-in-tube exchanger, plate exchanger,...

Product

Description

This equipment consists of a service unit that supplies the necessary utilities and measuring instruments to carry out tests on five types of heat exchangers: tube-in-tube exchanger, plate exchanger, shell-and-tube exchanger, jacketed tank and crossflow exchanger. The minimum purchasable configuration includes the service unit and one of these four exchangers. A data acquisition software with interface system is available as optional item.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Heat transfer between fluids separated by a wall

• Energy balance and calculation of efficiency

• Log Mean Temperature Difference (LMTD)

• Overall heat transfer coefficient (U)

• How flow rate and of temperature difference can affect the transfer coefficient

• Comparing the operating modes and performance of different types of heat exchangers

TECHNICAL SPECIFICATIONS:

Service unit

• Bench-top framework of AISI 304 stainless steel

• Hot water generator of AISI 304 stainless steel with electronic temperature control, pump, heater of 2 kW and level switch

• Pressure controller of cold water

• 2 electronic flowmeters

• 6 thermo-resistances Pt100

• Switchboard of painted carbon steel with ELCB

• All data can be acquired by PC via the optional data acquisition software with interface system

• Power supply: 230 Vac 50 Hz single-phase - 3 kVA (Other voltage and frequency on request)

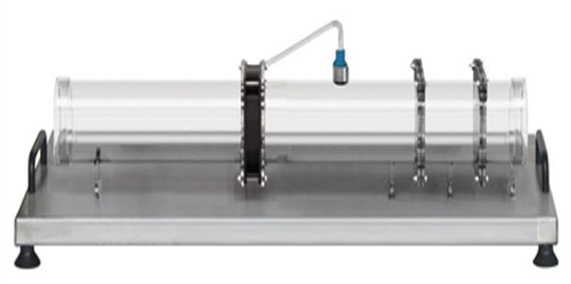

Tube-in-tube heat exchanger

• 6 sections of double pipes (outer pipe of transparent Plexiglas, inner pipe of stainless steel)

• Possibility of using 2, 4 or 6 sections to change the total exchange surface (0.027, 0.054 and 0.081 m2)

• Pipes can easily be disassembled for cleaning

Plate-type heat exchanger

• 10 plates of stainless steel with exchange surface of 0.1 m2

Shell-and-tube heat exchanger

• Shell of transparent Plexiglas with two baffles

• 7 (removable) inner pipes of stainless steel

• Surface of 0.02 m2

Jacket tank heat exchanger

• Tank with jacket and coil

• Stirrer of variable speed with baffle

Crossflow heat exchanger

• Rectangular duct

• Radiator with fan

• Air speed sensor

Supervision software with interface

• for Windows

• Synoptic with the values of the measured variables

• Real-time trend

• Historical trend

quick overview :

This equipment consists of a service unit that supplies the necessary utilities and measuring instruments to carry out tests on five types of heat exchangers: tube-in-tube exchanger, plate exchanger, shell-and-tube exchanger, jacketed tank and crossflow exchanger. The minimum purchasable configuration includes the service unit and one of these four exchangers. A data acquisition software with interface system is available as optional item.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Heat transfer between fluids separated by a wall

• Energy balance and calculation of efficiency

• Log Mean Temperature Difference (LMTD)

• Overall heat transfer coefficient (U)

• How flow rate and of temperature difference can affect the transfer coefficient

• Comparing the operating modes and performance of different types of heat exchangers

TECHNICAL SPECIFICATIONS:

Service unit

• Bench-top framework of AISI 304 stainless steel

• Hot water generator of AISI 304 stainless steel with electronic temperature control, pump, heater of 2 kW and level switch

• Pressure controller of cold water

• 2 electronic flowmeters

• 6 thermo-resistances Pt100

• Switchboard of painted carbon steel with ELCB

• All data can be acquired by PC via the optional data acquisition software with interface system

• Power supply: 230 Vac 50 Hz single-phase - 3 kVA (Other voltage and frequency on request)

Tube-in-tube heat exchanger

• 6 sections of double pipes (outer pipe of transparent Plexiglas, inner pipe of stainless steel)

• Possibility of using 2, 4 or 6 sections to change the total exchange surface (0.027, 0.054 and 0.081 m2)

• Pipes can easily be disassembled for cleaning

Plate-type heat exchanger

• 10 plates of stainless steel with exchange surface of 0.1 m2

Shell-and-tube heat exchanger

• Shell of transparent Plexiglas with two baffles

• 7 (removable) inner pipes of stainless steel

• Surface of 0.02 m2

Jacket tank heat exchanger

• Tank with jacket and coil

• Stirrer of variable speed with baffle

Crossflow heat exchanger

• Rectangular duct

• Radiator with fan

• Air speed sensor

Supervision software with interface

• for Windows

• Synoptic with the values of the measured variables

• Real-time trend

• Historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.