Heat Transfer Pilot Plant with Tube-in-Tube, Shell-and-Tube and Plate Exchangers

Categories: Chemical Engineering Manufacturer and SupplierThis unit enables to study heat exchanges by using a tube-intube exchanger, a shell-and-tube exchanger or a plate heat exchanger. The automated version includes a PID controller that controls flow rat...

Product

Description

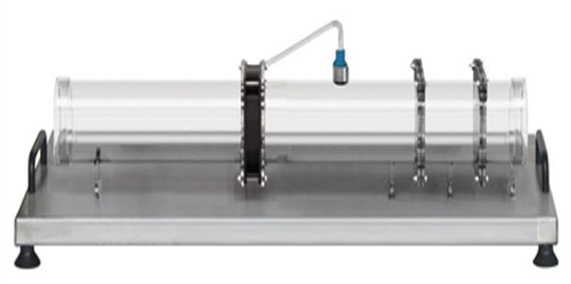

This unit enables to study heat exchanges by using a tube-intube exchanger, a shell-and-tube exchanger or a plate heat exchanger. The automated version includes a PID controller that controls flow rates automatically via two pneumatic valves.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Heat transfer between fluids separated by a wall in co-current and counter-current

• Energy balance and calculation of efficiency

• Log Mean Temperature Difference (LMTD)

• Overall heat transfer coefficient (U)

• How flow rate and of temperature difference can affect the transfer coefficient

• Comparing the operating modes and performance of different types of heat exchangers

• Automatic flow control by PID controller

• System supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Tube-in-tube heat exchanger of AISI 304 stainless steel, with exchange surface of 0.1 m2

• Shell-and-tube heat exchanger with shell of borosilicate glass and tubes of AISI 304 stainless steel, with exchange surface of 0.1 m2

• Plate-type heat exchanger of AISI 304 stainless steel, with exchange surface of 0.1 m2

• 2 magnetic induction flow meters with range of 0 to 1000 l/h, 4-20 mA output signal

• 2 pneumatic control valves of AISI 316 stainless steel, DN 15, Cv = 2.5

• 12 temperature sensors Pt 100 with sheath of AISI 316 stainless steel

• 12 electronic temperature indicators

• 2 manual controls for adjusting pneumatic valves

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

Besides being provided with all the characteristics, this model also includes the following additional items:

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• 2 microprocessor digital PID controllers with serial cards

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

quick overview :

This unit enables to study heat exchanges by using a tube-intube exchanger, a shell-and-tube exchanger or a plate heat exchanger. The automated version includes a PID controller that controls flow rates automatically via two pneumatic valves.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Heat transfer between fluids separated by a wall in co-current and counter-current

• Energy balance and calculation of efficiency

• Log Mean Temperature Difference (LMTD)

• Overall heat transfer coefficient (U)

• How flow rate and of temperature difference can affect the transfer coefficient

• Comparing the operating modes and performance of different types of heat exchangers

• Automatic flow control by PID controller

• System supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Tube-in-tube heat exchanger of AISI 304 stainless steel, with exchange surface of 0.1 m2

• Shell-and-tube heat exchanger with shell of borosilicate glass and tubes of AISI 304 stainless steel, with exchange surface of 0.1 m2

• Plate-type heat exchanger of AISI 304 stainless steel, with exchange surface of 0.1 m2

• 2 magnetic induction flow meters with range of 0 to 1000 l/h, 4-20 mA output signal

• 2 pneumatic control valves of AISI 316 stainless steel, DN 15, Cv = 2.5

• 12 temperature sensors Pt 100 with sheath of AISI 316 stainless steel

• 12 electronic temperature indicators

• 2 manual controls for adjusting pneumatic valves

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Power supply: 230 Vac 50 Hz single-phase - 0.5 kVA (Other voltage and frequency on request)

Besides being provided with all the characteristics, this model also includes the following additional items:

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• 2 microprocessor digital PID controllers with serial cards

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.