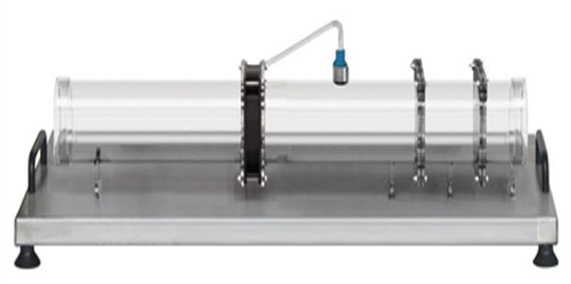

Liquid-Liquid Extraction Pilot Plant

Categories: Chemical Engineering Manufacturer and SupplierThis unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom p...

Product

Description

This unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom phase separators and with two other tanks for collecting the refined and extracted products. This unit is available in two versions:

• With “rotating-disc” extraction column

• With “packed” extraction column

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of the number of transfer units

• Height of a transfer unit

• Extraction efficiency

• Mass balance

• Calculation of mass transfer coefficient

• Calculation of the number of theoretical stages

• Exercises on 3-component systems (e.g.: acetic acid – toluene – water)

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extraction column of borosilicate glass, DN50, h = 600 mm, including disc agitator and motor with tachogenerator

• Electronic indicator of agitator speed

• Extraction column of borosilicate glass, DN50, h = 600 mm, with Raschig rings

• Top separator of borosilicate glass

• Bottom separator of borosilicate glass

• 2 metering pumps with body of AISI 316 stainless steel, flow rate of 0 to 40 l/h

• Feeding tank of plastic material for the light phase, with capacity of 30 l

• Feeding tank of plastic material for the heavy phase, with capacity of 30 l

• Tank of plastic material, with capacity of 30 l, for collecting the extracted product

• Tank of plastic material, with capacity of 30 l, for collecting the refined product

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 1 kVA (Other voltage and frequency on request)

quick overview :

This unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom phase separators and with two other tanks for collecting the refined and extracted products. This unit is available in two versions:

• With “rotating-disc” extraction column

• With “packed” extraction column

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of the number of transfer units

• Height of a transfer unit

• Extraction efficiency

• Mass balance

• Calculation of mass transfer coefficient

• Calculation of the number of theoretical stages

• Exercises on 3-component systems (e.g.: acetic acid – toluene – water)

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extraction column of borosilicate glass, DN50, h = 600 mm, including disc agitator and motor with tachogenerator

• Electronic indicator of agitator speed

• Extraction column of borosilicate glass, DN50, h = 600 mm, with Raschig rings

• Top separator of borosilicate glass

• Bottom separator of borosilicate glass

• 2 metering pumps with body of AISI 316 stainless steel, flow rate of 0 to 40 l/h

• Feeding tank of plastic material for the light phase, with capacity of 30 l

• Feeding tank of plastic material for the heavy phase, with capacity of 30 l

• Tank of plastic material, with capacity of 30 l, for collecting the extracted product

• Tank of plastic material, with capacity of 30 l, for collecting the refined product

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 1 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.