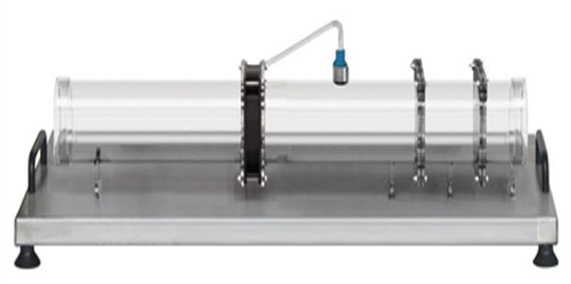

Liquid-Liquid Extraction Pilot Plant (Large Line)

Categories:This unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom p...

Product

Description

This unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom phase separators and with two other tanks for collecting the refined and extracted products. This unit is available in two versions: with rotating disc column or with Raschig rings packed column; each version may be manual or automated:

• manual version with rotating-disc column

• automated version with rotating-disc column

• manual version with Raschig rings packed column

• automated version with Raschig rings packed column.

The automated versions are equipped with PID controller to control automatically the level in the column, also the r.p.m. of the stirrer motor

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of the number of transfer units

• Height of a transfer unit

• Extraction efficiency

• Mass balance

• Calculation of mass transfer coefficient

• Calculation of the number of theoretical stages

• Trend of concentrations along the column

• Exercises on systems of 3 partially mixable components:

- acetic acid – toluene – water

- acetic acid – isopropyl ether – water

- acetic acid – ethyl acetate – water

• Automatic control with PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extraction column of borosilicate glass, DN50, consisting of 26 stages, h = 1500 mm, and including stirrer with discs of AISI 316 stainless steel , top and bottom separators of borosilicate glass and variable speed motor (0 to 1000 rpm) with tachogenerator

• Extraction column of borosilicate glass, DN 50, h = 1500 mm, with Raschig rings packing, including top and bottom separators of borosilicate glass

• 4 graduated tanks of borosilicate glass, with capacity of 25 l

• Metering double-body pump of AISI 316 stainless steel, with flow rate of 0 to 30 l/h, including pneumatic actuator adjustable with signal of 0.2 to1 bar

• Pneumatic control valve of AISI 316 stainless steel, DN 15, Cv = 0.13

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Electronic temperature indicator

• 3 manual pneumatic control devices

• Piping and valves of AISI 304 and 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the technical specifications, this model also includes the following additional items:

• Electronic level transmitter of AISI 316 stainless steel, differential pressure type, with range of 0 to 200 mm H2O, 4-20 mA output signal

• 3 electro-pneumatic converters 4 to 20 mA/0.2 to 1 bar

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from the PID controller, real-time trend and historical trend

quick overview :

This unit includes two separate tanks for the solvent and for the phase having to be refined, that are sent to the extraction column by two metering pumps; the column is provided with top and bottom phase separators and with two other tanks for collecting the refined and extracted products. This unit is available in two versions: with rotating disc column or with Raschig rings packed column; each version may be manual or automated:

• manual version with rotating-disc column

• automated version with rotating-disc column

• manual version with Raschig rings packed column

• automated version with Raschig rings packed column.

The automated versions are equipped with PID controller to control automatically the level in the column, also the r.p.m. of the stirrer motor

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determination of the number of transfer units

• Height of a transfer unit

• Extraction efficiency

• Mass balance

• Calculation of mass transfer coefficient

• Calculation of the number of theoretical stages

• Trend of concentrations along the column

• Exercises on systems of 3 partially mixable components:

- acetic acid – toluene – water

- acetic acid – isopropyl ether – water

- acetic acid – ethyl acetate – water

• Automatic control with PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extraction column of borosilicate glass, DN50, consisting of 26 stages, h = 1500 mm, and including stirrer with discs of AISI 316 stainless steel , top and bottom separators of borosilicate glass and variable speed motor (0 to 1000 rpm) with tachogenerator

• Extraction column of borosilicate glass, DN 50, h = 1500 mm, with Raschig rings packing, including top and bottom separators of borosilicate glass

• 4 graduated tanks of borosilicate glass, with capacity of 25 l

• Metering double-body pump of AISI 316 stainless steel, with flow rate of 0 to 30 l/h, including pneumatic actuator adjustable with signal of 0.2 to1 bar

• Pneumatic control valve of AISI 316 stainless steel, DN 15, Cv = 0.13

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Electronic temperature indicator

• 3 manual pneumatic control devices

• Piping and valves of AISI 304 and 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the technical specifications, this model also includes the following additional items:

• Electronic level transmitter of AISI 316 stainless steel, differential pressure type, with range of 0 to 200 mm H2O, 4-20 mA output signal

• 3 electro-pneumatic converters 4 to 20 mA/0.2 to 1 bar

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from the PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.