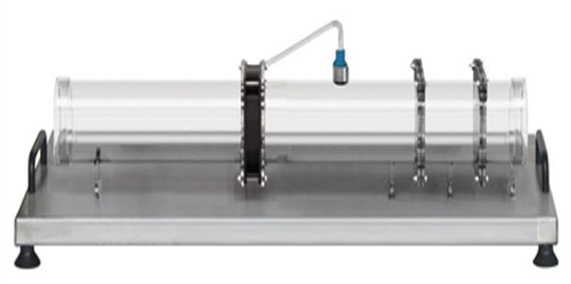

Pressure Losses Pilot Plant (Medium Line)

Categories: Chemical Engineering Manufacturer and SupplierThis equipment consists of a hydraulic circuit including pump and flowmeter and enabling to be connected with various hydraulic components, where the pressure drops on these elements can be measured....

Product

Description

This equipment consists of a hydraulic circuit including pump and flowmeter and enabling to be connected with various hydraulic components, where the pressure drops on these elements can be measured. The automated version includes a PID controller for the automatic control of the flow rate of the water crossing the circuit.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determining pressure drops in pipes of different diameter

• Determining pressure drops in bends and elbows

• Determining pressure drops in pipe expansions and restrictions

• Measuring the flow rate with calibrated orifice and computing the discharge coefficient α

• Measuring the flow rate with Venturi tube and computing the discharge coefficient α

• Checking the laminar, transition and turbulent flows by tracer

• Verifying Bernoulli’s theorem

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Centrifugal pump, with body and impeller of bronze, flow rate of 10 m3/h

• Electronic frequency inverter for the control of pump r.p.m.

• Tank of AISI 304 stainless steel, with capacity of 80 l

• Stainless steel differential mercury gauge (mercury not supplied; the instrument can be replaced with a digital pressure gauge on request during order placement)

• Flowmeter of steel and glass, with range of 1 to 10 m3/h

• Pipe of AISI 304 stainless steel of ½”

• Pipe of AISI 304 stainless steel of ¾”

• Pipe of AISI 304 stainless steel with U bends

• Pipe of AISI 304 stainless steel with L bends

• Pipe of AISI 304 stainless steel with sudden expansion and restriction

• Pipe of AISI 304 stainless steel with calibrated orifice

• Pipe of AISI 304 stainless steel with Venturi tube of Plexiglas

• Pipe of borosilicate glass for checking the laminar and turbulent flows by tracer

• Tank of borosilicate glass, with capacity of 1 l, for tracer

• Bourdon gauge of AISI 304 stainless steel with range of 0 to 6 bar

• Thermometer with range of 0 to 120 °C

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 3,2 kVA (Other voltage and frequency on request)

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 10000 mm H2O and 4-20 mA output signal

• Electronic variable area flow transmitter of AISI 304 stainless steel, with range of 1 to 10 m3/h and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 10000 mmH2O and 4-20 mA output signal

• Electronic variable area flow transmitter of AISI 304 stainless steel, with range of 1 to 10 m3/h and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

quick overview :

This equipment consists of a hydraulic circuit including pump and flowmeter and enabling to be connected with various hydraulic components, where the pressure drops on these elements can be measured. The automated version includes a PID controller for the automatic control of the flow rate of the water crossing the circuit.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Determining pressure drops in pipes of different diameter

• Determining pressure drops in bends and elbows

• Determining pressure drops in pipe expansions and restrictions

• Measuring the flow rate with calibrated orifice and computing the discharge coefficient α

• Measuring the flow rate with Venturi tube and computing the discharge coefficient α

• Checking the laminar, transition and turbulent flows by tracer

• Verifying Bernoulli’s theorem

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Centrifugal pump, with body and impeller of bronze, flow rate of 10 m3/h

• Electronic frequency inverter for the control of pump r.p.m.

• Tank of AISI 304 stainless steel, with capacity of 80 l

• Stainless steel differential mercury gauge (mercury not supplied; the instrument can be replaced with a digital pressure gauge on request during order placement)

• Flowmeter of steel and glass, with range of 1 to 10 m3/h

• Pipe of AISI 304 stainless steel of ½”

• Pipe of AISI 304 stainless steel of ¾”

• Pipe of AISI 304 stainless steel with U bends

• Pipe of AISI 304 stainless steel with L bends

• Pipe of AISI 304 stainless steel with sudden expansion and restriction

• Pipe of AISI 304 stainless steel with calibrated orifice

• Pipe of AISI 304 stainless steel with Venturi tube of Plexiglas

• Pipe of borosilicate glass for checking the laminar and turbulent flows by tracer

• Tank of borosilicate glass, with capacity of 1 l, for tracer

• Bourdon gauge of AISI 304 stainless steel with range of 0 to 6 bar

• Thermometer with range of 0 to 120 °C

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

• Power supply: 230 Vac 50 Hz single-phase - 3,2 kVA (Other voltage and frequency on request)

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 10000 mm H2O and 4-20 mA output signal

• Electronic variable area flow transmitter of AISI 304 stainless steel, with range of 1 to 10 m3/h and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Interface for the connection with a PC included in the switchboard

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic differential pressure transmitter of AISI 316 stainless steel, range of 0 to 10000 mmH2O and 4-20 mA output signal

• Electronic variable area flow transmitter of AISI 304 stainless steel, with range of 1 to 10 m3/h and 4-20 mA output signal

• Thermo-resistance Pt 100 with sheath of AISI 316 stainless steel

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2019 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.