Solid-Liquid Extraction Pilot Plant

Categories: Chemical Engineering Manufacturer and SupplierThis unit enables to study countercurrent solid-liquid extractions in a continuous extractor with Archimedean screw. The solid, stored in a hopper, is fed to the extractor via an Archimedean screw. Th...

Product

Description

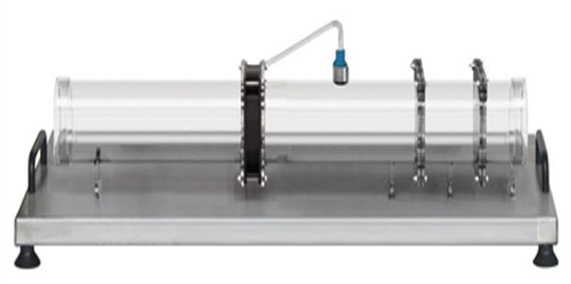

This unit enables to study countercurrent solid-liquid extractions in a continuous extractor with Archimedean screw. The solid, stored in a hopper, is fed to the extractor via an Archimedean screw. The solvent, stored in a tank, is sent to the top of the extractor by a metering pump. The solid phase is conveyed in the extractor by an Archimedean screw of PTFE, whereas the solvent will fall in countercurrent by gravity. Solvent and extracted product, as well as the exhausted solid, are stored in proper tanks. The automated version also includes a PID controller that enables to control the solvent pre-heating temperature automatically

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Calculation of the number of theoretical stages

• Study of the extraction performance versus the nature and flow rate of the solid, and the type, flow rate and temperature of the solvent

• Extraction of oil from soybean laminate with hexane

• Extraction of chorophyl from spinach with ethanol

• Extraction of oil from olive husk with hexane

• Extraction of starch from potatoes with water

• Automatic temperature control with PID controller

• Plant supervision by PC

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extractor of borosilicate glass, DN 100, l = 1000 mm, with Archimedean screw of PTFE

• Hopper of AISI 304 stainless steel with capacity of 2 l, for storing the solid

• Geared motor for solid feeding Archimedean screw, with speed of 0 to 20 r.p.m.

• Geared motor for the Archimedean screw of the extractor, with speed of 0 to 10 r.p.m.

• 2 programmable timers for controlling the starting and stopping times of the feeding Archimedean screw

• Tank of borosilicate glass for storing the solvent, with capacity of 10 l

• Tank of borosilicate glass for storing the extracted phase, with capacity of 10 l

• Tank of borosilicate glass for storing the exhausted solid, with capacity of 10 l

• Condenser of AISI 304 stainless steel, with exchange surface of 0.1 m²

• 3 thermo-resistances Pt 100 with sheath of AISI 316 stainless steel

• 3 electronic temperature indicators

• Thyristor unit for controlling the heating power

• Electric heater of quartz for solvent pre-heating, P = 0.3 kW

• Metering pump of AISI 316 stainless steel for the solvent, with flow rate of 0 to 12 l/h; it can be adjusted with signal of 0.2 to 1 bar by a pneumatic actuator

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

quick overview :

This unit enables to study countercurrent solid-liquid extractions in a continuous extractor with Archimedean screw. The solid, stored in a hopper, is fed to the extractor via an Archimedean screw. The solvent, stored in a tank, is sent to the top of the extractor by a metering pump. The solid phase is conveyed in the extractor by an Archimedean screw of PTFE, whereas the solvent will fall in countercurrent by gravity. Solvent and extracted product, as well as the exhausted solid, are stored in proper tanks. The automated version also includes a PID controller that enables to control the solvent pre-heating temperature automatically

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Calculation of the number of theoretical stages

• Study of the extraction performance versus the nature and flow rate of the solid, and the type, flow rate and temperature of the solvent

• Extraction of oil from soybean laminate with hexane

• Extraction of chorophyl from spinach with ethanol

• Extraction of oil from olive husk with hexane

• Extraction of starch from potatoes with water

• Automatic temperature control with PID controller

• Plant supervision by PC

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Extractor of borosilicate glass, DN 100, l = 1000 mm, with Archimedean screw of PTFE

• Hopper of AISI 304 stainless steel with capacity of 2 l, for storing the solid

• Geared motor for solid feeding Archimedean screw, with speed of 0 to 20 r.p.m.

• Geared motor for the Archimedean screw of the extractor, with speed of 0 to 10 r.p.m.

• 2 programmable timers for controlling the starting and stopping times of the feeding Archimedean screw

• Tank of borosilicate glass for storing the solvent, with capacity of 10 l

• Tank of borosilicate glass for storing the extracted phase, with capacity of 10 l

• Tank of borosilicate glass for storing the exhausted solid, with capacity of 10 l

• Condenser of AISI 304 stainless steel, with exchange surface of 0.1 m²

• 3 thermo-resistances Pt 100 with sheath of AISI 316 stainless steel

• 3 electronic temperature indicators

• Thyristor unit for controlling the heating power

• Electric heater of quartz for solvent pre-heating, P = 0.3 kW

• Metering pump of AISI 316 stainless steel for the solvent, with flow rate of 0 to 12 l/h; it can be adjusted with signal of 0.2 to 1 bar by a pneumatic actuator

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2019 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.