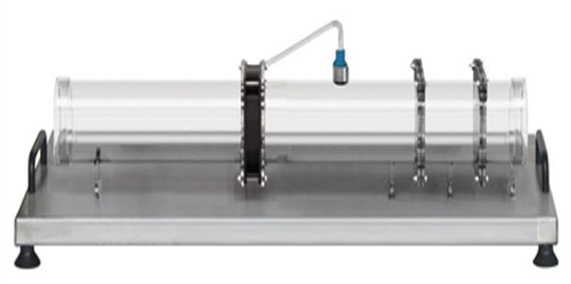

Thin Film Evaporation Pilot Plant (Large Line)

Categories:This evaporator consists of a cylindrical tube provided with a steam heating jacket and with a three-blade inner rotor that produces a very thin film of liquid on the walls. The solution having to be...

Product

Description

This evaporator consists of a cylindrical tube provided with a steam heating jacket and with a three-blade inner rotor that produces a very thin film of liquid on the walls. The solution having to be concentrated is transferred from the storage tank to the evaporator by a metering pump; the vaporized solvent is condensed in a shell-and-tube condenser and then it is collected into a tank. This type of evaporator is widely used in the industries for concentrating thermosensitive, viscous products, or dirtying products such as solutions containing sugar, enzymes, vitamins, proteins, fruit juices, fermentation broths, etc. The automated version is equipped with PID

controller that enables to control the flow rate of steam to the evaporator and the vacuum degree of the plant, automatically.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Mass balances

• Energy balances

• Determination of global heat transfer coefficient

• Optimization of evaporation process

• Automatic flow and vacuum control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Feeding tank of borosilicate glass, with capacity of 10 l

• Tank of borosilicate glass, with capacity of 10 l, for collecting the concentrated solution

• Tank of borosilicate glass, with capacity of 10 l, for collecting the evaporated solvent

• Thin-film evaporator of AISI 316 stainless steel, provided with 3-blade rotor 0.5 mm far from the wall; speed variable from 0 to 1500 rpm by inverter; exchange surface: 0.12 m2; evaporating capacity: 10 kg/h of H2O; double mechanical seal lubricated with silicone oil and water cooled

• Shell-and-tube condenser of AISI 304 stainless steel with exchange surface of 1.1 m2

• Feed metering pump of AISI 316 stainless steel (0 to 20 l/h), equipped with pneumatic actuator that can be driven by a signal of 0.2 to 1 bar

• Liquid-ring vacuum pump with air/water separator and solenoid on-off valve for feeding water

• Steam trap of AISI 304 stainless steel

• Pneumatic valve of AISI 316 stainless steel, Cv = 0.32, for the control of steam flow rate

• Differential-pressure transmitter of AISI 316 stainless steel for measuring the steam flow rate, with calibrated diaphragm of AISI 304 stainless steel

• 2 pressure gauges of AISI 304 stainless steel, with range of 0 to 1.6 and of 0 to 6 bar

• Vacuum gauge of AISI 304 stainless steel, with range of –1 to 0 bar

• 2 sight glasses of stainless steel

• 6 thermo-resistances Pt 100 with sheath of AISI 316 stainless steel

• 6 electronic temperature indicators

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic flow transmitter of differential pressure type, with body of AISI 316 stainless steel , range of 0 to 1000mm H2O, 4-20 mA output signal

• Electronic vacuum transmitter of AISI 316 stainless steel, with range of 0 to 1000 mbar and 4-20 mA output signal

• Interface (included in the switchboard) for the connection with a PC

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Pneumatic valve of AISI 316 stainless steel, Cv = 2.5, for the control of working pressure

• Electronic vacuum transmitter of AISI 316 stainless steel, with range of 0 to 1000 mbar and 4-20 mA output signal

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

quick overview :

This evaporator consists of a cylindrical tube provided with a steam heating jacket and with a three-blade inner rotor that produces a very thin film of liquid on the walls. The solution having to be concentrated is transferred from the storage tank to the evaporator by a metering pump; the vaporized solvent is condensed in a shell-and-tube condenser and then it is collected into a tank. This type of evaporator is widely used in the industries for concentrating thermosensitive, viscous products, or dirtying products such as solutions containing sugar, enzymes, vitamins, proteins, fruit juices, fermentation broths, etc. The automated version is equipped with PID

controller that enables to control the flow rate of steam to the evaporator and the vacuum degree of the plant, automatically.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Mass balances

• Energy balances

• Determination of global heat transfer coefficient

• Optimization of evaporation process

• Automatic flow and vacuum control by PID controller

• Plant supervision by P.C.

TECHNICAL SPECIFICATIONS:

• Framework of AISI 304 stainless steel with castors

• Feeding tank of borosilicate glass, with capacity of 10 l

• Tank of borosilicate glass, with capacity of 10 l, for collecting the concentrated solution

• Tank of borosilicate glass, with capacity of 10 l, for collecting the evaporated solvent

• Thin-film evaporator of AISI 316 stainless steel, provided with 3-blade rotor 0.5 mm far from the wall; speed variable from 0 to 1500 rpm by inverter; exchange surface: 0.12 m2; evaporating capacity: 10 kg/h of H2O; double mechanical seal lubricated with silicone oil and water cooled

• Shell-and-tube condenser of AISI 304 stainless steel with exchange surface of 1.1 m2

• Feed metering pump of AISI 316 stainless steel (0 to 20 l/h), equipped with pneumatic actuator that can be driven by a signal of 0.2 to 1 bar

• Liquid-ring vacuum pump with air/water separator and solenoid on-off valve for feeding water

• Steam trap of AISI 304 stainless steel

• Pneumatic valve of AISI 316 stainless steel, Cv = 0.32, for the control of steam flow rate

• Differential-pressure transmitter of AISI 316 stainless steel for measuring the steam flow rate, with calibrated diaphragm of AISI 304 stainless steel

• 2 pressure gauges of AISI 304 stainless steel, with range of 0 to 1.6 and of 0 to 6 bar

• Vacuum gauge of AISI 304 stainless steel, with range of –1 to 0 bar

• 2 sight glasses of stainless steel

• 6 thermo-resistances Pt 100 with sheath of AISI 316 stainless steel

• 6 electronic temperature indicators

• Piping and valves of AISI 304 and AISI 316 stainless steel

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency button

Besides being provided with all the characteristics, this model also includes the following additional items:

• Electronic flow transmitter of differential pressure type, with body of AISI 316 stainless steel , range of 0 to 1000mm H2O, 4-20 mA output signal

• Electronic vacuum transmitter of AISI 316 stainless steel, with range of 0 to 1000 mbar and 4-20 mA output signal

• Interface (included in the switchboard) for the connection with a PC

• Data acquisition software for Windows

Besides being provided with all the characteristics, this model also includes the following additional items:

• Pneumatic valve of AISI 316 stainless steel, Cv = 2.5, for the control of working pressure

• Electronic vacuum transmitter of AISI 316 stainless steel, with range of 0 to 1000 mbar and 4-20 mA output signal

• Microprocessor digital PID controller with serial card

• Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID controller, real-time trend and historical trend

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.