Three Phase Separation Trainer

Categories: Chemical Engineering Manufacturer and SupplierIn this trainer air, water and oil are mixed to emulate a crude oil stream. This fluid mixture flows into a horizontal separator vesselfabricated of clear Plexiglas and equipped with industry-typical...

Product

Description

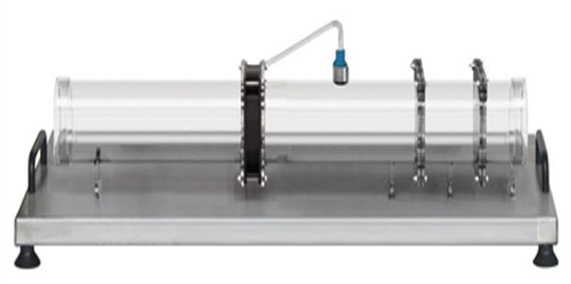

In this trainer air, water and oil are mixed to emulate a crude oil stream. This fluid mixture flows into a horizontal separator vessel

fabricated of clear Plexiglas and equipped with industry-typical process measurement devices. Separator works on the principle that the three components have different densities, which allows them to stratify when moving slowly with gas on top, water on the bottom and oil in the middle. The separator vessel is equipped of diverter baffle, demister and control loop for air and oil flow rate, for the level of oil, water and a loop for controlling the gas pressure. The liquid separated products are recollected by gravity to feed

tanks and gas (air) vented. The system is equipped with two PID controllers with electric and pneumatic system and it is integrated with computerized control system (SCADA).

Note that the process uses safety fluid in operation (water, oil, air) and have emergence push button.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Mass balance and separator design

• Measurements, instrumentation and PID control

• Automatic flow rate control

• Automatic level control

• Automatic pressure control

• Functioning of separator in different operative condition (flow of water, oil, air, pressure)

TECHNICAL SPECIFICATIONS:

• AISI 304 stainless steel structure with castors

• 50 litres AISI 304 stainless steel water tank

• 50 litres AISI 304 stainless steel oil tank

• Clear plastic horizontal separator, d = 300 mm, L = 600 mm

• Metering pump for water

• Gear pump for oil

• Compressor for air feeding

• Thermal mass flow meter for air

• Gear flowmeter for oil

• Differential pressure transmitter, made of AISI 316 stainless steel, range 0-500 mmH2O

• Differential pressure transmitter, made of AISI 316 stainless steel, range 0-300 mmH2O

• Pressure transmitter, made of AISI 316 stainless steel, range 0-0.5 bar

• Pneumatic control valve for air flow control, AISI 316 stainless steel

• Pneumatic control valve for pressure control, AISI 316 stainless steel

• Pneumatic control valve for water level control, AISI 316 stainless steel

• Pneumatic control valve for oil level control, AISI 316 stainless steel

• Pressure safety valve calibrated @ 0.5 bar

• High level switch

• Connecting lines and valves of AISI 304 and 316 stainless steel

• 2 microprocessor PID controllers

• IP 55 switchboard with E.L.C.B. and plant synoptic

• Emergency pushbutton

• Power supply: 230 Vac 50 Hz single-phase - 0,5 kVA (Other voltage and frequency on request)

quick overview :

In this trainer air, water and oil are mixed to emulate a crude oil stream. This fluid mixture flows into a horizontal separator vessel

fabricated of clear Plexiglas and equipped with industry-typical process measurement devices. Separator works on the principle that the three components have different densities, which allows them to stratify when moving slowly with gas on top, water on the bottom and oil in the middle. The separator vessel is equipped of diverter baffle, demister and control loop for air and oil flow rate, for the level of oil, water and a loop for controlling the gas pressure. The liquid separated products are recollected by gravity to feed

tanks and gas (air) vented. The system is equipped with two PID controllers with electric and pneumatic system and it is integrated with computerized control system (SCADA).

Note that the process uses safety fluid in operation (water, oil, air) and have emergence push button.

TRAINING PROGRAM

This unit enables to deepen the following issues:

• Mass balance and separator design

• Measurements, instrumentation and PID control

• Automatic flow rate control

• Automatic level control

• Automatic pressure control

• Functioning of separator in different operative condition (flow of water, oil, air, pressure)

TECHNICAL SPECIFICATIONS:

• AISI 304 stainless steel structure with castors

• 50 litres AISI 304 stainless steel water tank

• 50 litres AISI 304 stainless steel oil tank

• Clear plastic horizontal separator, d = 300 mm, L = 600 mm

• Metering pump for water

• Gear pump for oil

• Compressor for air feeding

• Thermal mass flow meter for air

• Gear flowmeter for oil

• Differential pressure transmitter, made of AISI 316 stainless steel, range 0-500 mmH2O

• Differential pressure transmitter, made of AISI 316 stainless steel, range 0-300 mmH2O

• Pressure transmitter, made of AISI 316 stainless steel, range 0-0.5 bar

• Pneumatic control valve for air flow control, AISI 316 stainless steel

• Pneumatic control valve for pressure control, AISI 316 stainless steel

• Pneumatic control valve for water level control, AISI 316 stainless steel

• Pneumatic control valve for oil level control, AISI 316 stainless steel

• Pressure safety valve calibrated @ 0.5 bar

• High level switch

• Connecting lines and valves of AISI 304 and 316 stainless steel

• 2 microprocessor PID controllers

• IP 55 switchboard with E.L.C.B. and plant synoptic

• Emergency pushbutton

• Power supply: 230 Vac 50 Hz single-phase - 0,5 kVA (Other voltage and frequency on request)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2019 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.