- Educational lab Equipment

- Engineering Lab

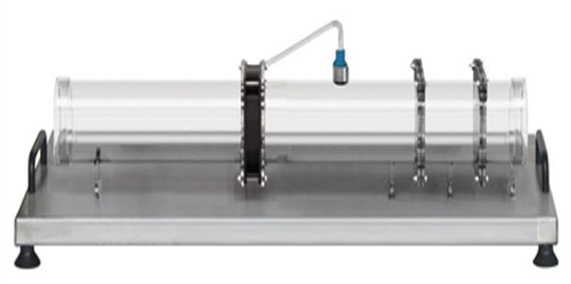

Tray Dryer Apparatus

Tray Dryer Apparatus

Categories: Chemical Engineering Manufacturer and SupplierThis dryer has been designed to study the commonest industrial drying method of solids consisting in blowing a flow of hot air onto some trays where wet material is arranged. The unit consists of a tu...

Product

Description

quick overview :

Product

Reviews

add Review

reviews

No Review Yet.

Related

Products

4 WAY LABORATORY TEST TUBE RACK

4 Way Laboratory Test Tube Rack4 Way Laboratory Test Tube...

Absorption and Stripping Pilot Plant (La...

This absorption and stripping system enables to study the ma...

Absorption Pilot Plant (Medium Line)

This absorption unit has been designed to explain the princi...

Apparatus for the Study of Ternary Syste...

This equipment enables to study the balances of ternary liqu...

The unit is composed by an axial fan mounted on a stainless...

Batch Distillation Pilot Plant (Large Li...

The distillation column is completely made of glass and it c...

Batch Distillation Pilot Plant (Medium L...

The distillation column is made completely of glass and it c...

Batch Distillation Pilot Plant

This distillation column is completely of glass and it consi...

Tray Dryer Apparatus - Query

Success!

Success

AticoExport © 2018 | Advanced Technocracy Inc.

Atico Export is providing its services to following countries: Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Anguilla, Antigua & Barbuda, Argentina, Armenia, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bonaire, Bosnia & Herzegovina, Botswana, Brazil, British Indian Ocean Ter, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Canary Islands, Cape Verde, Cayman Islands, Central African Republic, Chad, Channel Islands, Chile, China, Christmas Island, Colombia, Cocos Island, Comoros, Congo, Cook Islands, Costa Rica, Cote DIvoire, Croatia, Cuba, Curacao, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, East Timor, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Ter, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Great Britain, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guyana, Haiti, Hawaii, Honduras, Hong Kong, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Isle of Man, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Korea North, Korea South, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau, Macedonia, Madagascar, Malaysia, Malawi, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Midway Islands, Moldova, Monaco, Mongolia, Montserrat, Morocco, Mozambique, Myanmar, Nambia, Nauru, Nepal, Netherland Antilles, Netherlands (Holland, Europe), Nevis, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Norway, Oman, Pakistan, Palau Island, Palestine, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Island, Poland, Portugal, Puerto Rico, Qatar, Republic of Montenegro, Republic of Serbia, Reunion, Romania, Russia, Rwanda, St Barthelemy, St Eustatius, St Helena, St Kitts-Nevis, St Lucia, St Maarten, St Pierre & Miquelon, St Vincent & Grenadines, Saipan, Samoa, Samoa American, San Marino, Sao Tome & Principe, Saudi Arabia, Senegal, Serbia, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, Spain, Sri Lanka, Sudan, Suriname, Swaziland, Sweden, Switzerland, Syria, Tahiti, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tokelau, Tonga, Trinidad & Tobago, Tunisia, Turkey, Turkmenistan, Turks & Caicos Is, Tuvalu, Uganda, Ukraine, United Arab Emirates, United Kingdom, United States of America, Uruguay, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Vietnam, Virgin Islands (Brit), Virgin Islands (USA), Wake Island, Wallis & Futana Is, Yemen, Zaire, Zambia, Zimbabwe

Copyrights © 2019 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.