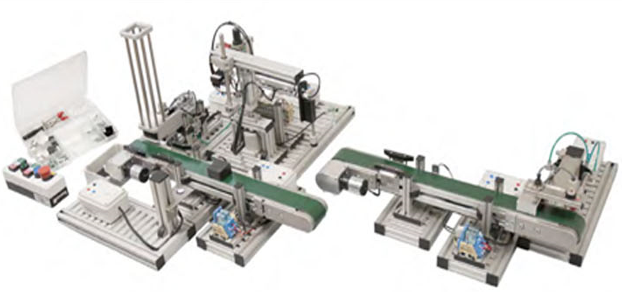

Automatic Weighting and Selection System with Pneumatic Robot and Double Conveyor

Categories: Automation TechnologiesThe mechatronic system consists of the following elements:• Storage module for prismatic pieces• 2 conveyor modules• Robot module• Weighting module• Module for testing and selecting pieces• Pushbutton...

Product

Description

The mechatronic system consists of the following elements:

• Storage module for prismatic pieces

• 2 conveyor modules

• Robot module

• Weighting module

• Module for testing and selecting pieces

• Pushbutton panel

• Box of tools and workpieces

Description of the cycle:

The working cycle, completely controlled by PLC, consists of:

• The piece is ejected from the storage module to the conveyor module 1

• Conveyor 1 transports the piece until the Optical Fiber sensor detects its presence and stops Conveyor 1;

• The piece is picked up by the robot module

• The piece is put on the weighting module

• Piece weighting (the piece is accepted or rejected).

If the piece complies with the preset weight, the working cycle continues as follows:

• The piece is taken from the weighting module and put on Conveyor module 2.

• Conveyor module 2 starts for material and color identification (plastic or aluminum/white or black) with inductive / optical sensors.

• Pieces are then classified and stored by the Module for Testing and Selecting pieces according to the above mentioned parameters

If the piece does not comply with the preset weight, the working cycle follows in this way:

• The piece is taken from the weighting module and put on Conveyor module 1.

• Conveyor module 1 starts again and the piece is stored in the storage module.

The complete system is managed by PLC.

PLC (not included) is required for controlling the process and must have at least:

• 17 digital inputs 24 VDC

• 13 digital outputs 24 VDC 0.5 A

• 1 Analog input 0-10 V

Suggested PLC:

2 PLC trainers interconnected via PROFINET industrial data network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 2 PLC trainers with programming and simulation software, interconnected via PROFINET industrial network or PROFIBUS data network.

Connection to the modules is carried out via 2 mm sockets.

quick overview :

The mechatronic system consists of the following elements:

• Storage module for prismatic pieces

• 2 conveyor modules

• Robot module

• Weighting module

• Module for testing and selecting pieces

• Pushbutton panel

• Box of tools and workpieces

Description of the cycle:

The working cycle, completely controlled by PLC, consists of:

• The piece is ejected from the storage module to the conveyor module 1

• Conveyor 1 transports the piece until the Optical Fiber sensor detects its presence and stops Conveyor 1;

• The piece is picked up by the robot module

• The piece is put on the weighting module

• Piece weighting (the piece is accepted or rejected).

If the piece complies with the preset weight, the working cycle continues as follows:

• The piece is taken from the weighting module and put on Conveyor module 2.

• Conveyor module 2 starts for material and color identification (plastic or aluminum/white or black) with inductive / optical sensors.

• Pieces are then classified and stored by the Module for Testing and Selecting pieces according to the above mentioned parameters

If the piece does not comply with the preset weight, the working cycle follows in this way:

• The piece is taken from the weighting module and put on Conveyor module 1.

• Conveyor module 1 starts again and the piece is stored in the storage module.

The complete system is managed by PLC.

PLC (not included) is required for controlling the process and must have at least:

• 17 digital inputs 24 VDC

• 13 digital outputs 24 VDC 0.5 A

• 1 Analog input 0-10 V

Suggested PLC:

2 PLC trainers interconnected via PROFINET industrial data network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 2 PLC trainers with programming and simulation software, interconnected via PROFINET industrial network or PROFIBUS data network.

Connection to the modules is carried out via 2 mm sockets.

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.