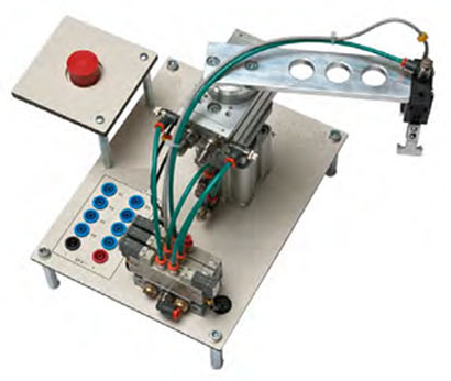

Manipulating Arm

Categories: Automation TechnologiesManipulating arm is designed to grab and release pieces in two different positions. It includes a double effect cylinder to move the piece up and down, a rotary cylinder to transport the piece b...

Product

Description

Manipulating arm is designed to grab and release pieces in two different positions. It includes a double effect cylinder to move the piece up and down, a rotary cylinder to transport the piece between the two positions and a pneumatic gripper. Different types of sensors (magnetic / inductive) enable the identification of the arm’s position and of the gripper state (close/open). A typical working cycle is as follows. When the piece is placed

on the starting point, the arm:

• Rises and turns until it is above the piece

• Lowers and grips the piece

• Rises again and makes a 180° turn

• Lowers, opens the gripper to release the piece and rises again

TRAINING PROGRAM:

• Working cycle analysis

• System I/O definition

• Process diagram

• Working cycle phases list

• Logic scheme definition

• Analysis of potential problems

• Program writing

TECHNICAL SPECIFICATIONS:

Electric characteristics

• Rotary actuator with flange

• Gripper

• 1 inductive sensor

• 3 magnetic sensors

• 2 5/2 monostable electrovalves

• 1 5/2 bistable electrovalves

• 5 flow regulators

• 10 Terminals ø 4mm

Mechanic characteristics

Silk screen synoptic bakelite panel with pins.

A PLC (not included) is needed to control the process. Minimum requirements:

• 4 24Vcc digital inputs

• 4 24Vcc transistor digital outputs

Suggested PLC:

• PLC training panel mod. PLC-V7/EV to control the system.

Alternative:

• PLC training panel mod. PLC-V8/EV

• Power supply: 24 Vcc – 0.5A (from the PLC)

quick overview :

Manipulating arm is designed to grab and release pieces in two different positions. It includes a double effect cylinder to move the piece up and down, a rotary cylinder to transport the piece between the two positions and a pneumatic gripper. Different types of sensors (magnetic / inductive) enable the identification of the arm’s position and of the gripper state (close/open). A typical working cycle is as follows. When the piece is placed

on the starting point, the arm:

• Rises and turns until it is above the piece

• Lowers and grips the piece

• Rises again and makes a 180° turn

• Lowers, opens the gripper to release the piece and rises again

TRAINING PROGRAM:

• Working cycle analysis

• System I/O definition

• Process diagram

• Working cycle phases list

• Logic scheme definition

• Analysis of potential problems

• Program writing

TECHNICAL SPECIFICATIONS:

Electric characteristics

• Rotary actuator with flange

• Gripper

• 1 inductive sensor

• 3 magnetic sensors

• 2 5/2 monostable electrovalves

• 1 5/2 bistable electrovalves

• 5 flow regulators

• 10 Terminals ø 4mm

Mechanic characteristics

Silk screen synoptic bakelite panel with pins.

A PLC (not included) is needed to control the process. Minimum requirements:

• 4 24Vcc digital inputs

• 4 24Vcc transistor digital outputs

Suggested PLC:

• PLC training panel mod. PLC-V7/EV to control the system.

Alternative:

• PLC training panel mod. PLC-V8/EV

• Power supply: 24 Vcc – 0.5A (from the PLC)

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.