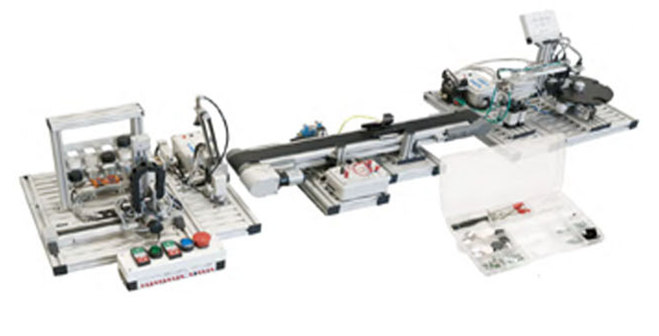

Multilevel Storage System with Piece Testing Station on Rotary Indexing Table and Conveyor Module in Closed Loop Mode

Categories: Automation TechnologiesThe mechatronic system consists of the following elements:• Swivel arm manipulator module• Rotary indexing table module• Pneumatic arm module• Cartesian control storage module• Conveyor module• Pushbu...

Product

Description

The mechatronic system consists of the following elements:

• Swivel arm manipulator module

• Rotary indexing table module

• Pneumatic arm module

• Cartesian control storage module

• Conveyor module

• Pushbutton panel

• Touchscreen operator panel

• Box of tools and workpiece

Description of the cycle:

The working cycle, completely controlled by PLC, consists of:

• The piece is withdraw from the Cartesian storage module.

• The piece is deposited on the conveyor module

• The piece is transported to the next station

• The piece is picked up from the conveyor module and released on the piece control module

• A set of sensors (inductive and optical) identify the material and color of the piece

• The piece is returned to Cartesian storage module

• The piece is stored complying with the data coming from the previous tests.

The complete system is managed by PLC.

PLC (not included) is required for controlling the process and must have at least:

• 23 digital inputs 24 VDC

• 18 digital outputs 24 VDC 0.5 A

Suggested PLCs:

2 PLC trainers interconnected via PROFINET industrial data network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 2 PLC trainers with programming and simulation software, interconnected via PROFINET industrial network or PROFIBUS data network. Connection to the modules is carried out via 2 mm sockets.

quick overview :

The mechatronic system consists of the following elements:

• Swivel arm manipulator module

• Rotary indexing table module

• Pneumatic arm module

• Cartesian control storage module

• Conveyor module

• Pushbutton panel

• Touchscreen operator panel

• Box of tools and workpiece

Description of the cycle:

The working cycle, completely controlled by PLC, consists of:

• The piece is withdraw from the Cartesian storage module.

• The piece is deposited on the conveyor module

• The piece is transported to the next station

• The piece is picked up from the conveyor module and released on the piece control module

• A set of sensors (inductive and optical) identify the material and color of the piece

• The piece is returned to Cartesian storage module

• The piece is stored complying with the data coming from the previous tests.

The complete system is managed by PLC.

PLC (not included) is required for controlling the process and must have at least:

• 23 digital inputs 24 VDC

• 18 digital outputs 24 VDC 0.5 A

Suggested PLCs:

2 PLC trainers interconnected via PROFINET industrial data network. Connection to the modules is carried out via 2 mm sockets.

Alternative:

• 2 PLC trainers with programming and simulation software, interconnected via PROFINET industrial network or PROFIBUS data network. Connection to the modules is carried out via 2 mm sockets.

Product

Reviews

add Review

reviews

No Review Yet.

Copyrights © 2025 All Rights Reserved by Atico

Product

Reviews

add Review

reviews

No Review Yet.